1 ...6 7 8 10 11 12 ...19 Large companies often have strict rules that lead to a hierarchical culture. Startup technology companies that focus on innovation have an entrepreneurial culture. To take advantage of the latest technologies, these companies may need to start new programs that respond faster and have more flexibility for their suppliers.

Human resources teams often have a group culture, whereas consultants may have a rational culture. The human resources team may find the consultants rude and disinterested, and the consultants may view the human resources team as being nosy and unprofessional. For these groups to work effectively through a corporate merger, for example, you may need to schedule time for their members to interact in a social setting, such as a kickoff celebration.

You can also use an understanding of group personalities to choose teams to partner with in your supply chain. If your priority is creativity and innovation, for example, you’re likely to work best with supply chain partners that are driven by an entrepreneurial culture, and you’re probably going to be disappointed by a supply chain partner with a hierarchical culture.

Gattorna makes the point that supply chains are dynamic, so balancing these forces is an ongoing process. One way to create balance is to build teams of people that include each of these tendencies. If the team has a diverse set of personalities, its members are more likely to appreciate the strengths of diverse supply chain partners and find ways to build effective relationships with other teams.

Designing Supply Chain Systems

The most complicated way to understand a supply chain is to look at it as a system. (I think that this perspective is often the most useful.) Like many other systems that we encounter every day, supply chains are made up of interconnected components that can behave in unpredictable ways.

Your car is a good example. You expect your car to move you from Point A to Point B. In fact, you probably take for granted that your car will take you to Point B any time you want to go there. But your car is a system, and it can perform the way you expect it to only if all the components are operating correctly. A dead battery, a broken fuel pump, or worn-out brakes could bring the whole thing to a halt (or, in the case of the worn-out brakes, not bring it to a halt).

Supply chains are systems too. The components that make up supply chains are people, processes, and technologies. Each of these components needs to be organized and managed correctly for the system to operate as expected.

When you look at them as systems, you begin to see that supply chains have underlying rules and patterns that are key to understanding how they work. A good example of one of these patterns occurs when a company experiences wild swings in inventory levels. It can be difficult for people in the company to understand why these swings occur until you look at the supply chain as a system. Then you can recognize a pattern called the Bullwhip Effect, in which inventory peaks and valleys are amplified as they move upstream from one step to the next in a supply chain. The Bullwhip Effect, which occurs often in supply chain systems, is a normal, predictable result when everyone in the supply chain makes decisions that seem to be logical. To fix the problem, you need to change the system, which means understanding what is really happening.

Here’s a scenario that explains how a Bullwhip Effect can occur. A customer comes in to buy a widget, which turns out to be the last widget in the store, so the store needs to order more inventory from its wholesaler. But the wholesaler doesn’t sell individual widgets; it sells widgets in cases of 100 units. Now the store has to buy a full case — 100 widgets — even though it sold only one. If that case was the last one in the warehouse, the wholesaler will replenish its inventory by ordering more widgets from the factory. The factory, however, sells widgets in batches of 100 cases, so the wholesaler has to buy 100 cases of 100 widgets each. The wholesaler just bought 10,000 widgets even though it sold only 100.

How many widgets did the factory sell? 10,000. How many did the wholesaler sell? 100. And how many did the customer buy? Yep: 1. A small demand signal at the end of the supply chain became amplified at every step, creating a Bullwhip Effect on inventory. The store may never sell another widget, so it would still be stuck with 100 widgets in inventory. The wholesaler may never sell another case of widgets, so it may be stuck with 100 cases of widgets. All that extra inventory costs money for everyone in the supply chain without adding any value.

Here are three ways that you can change the system to reduce and even eliminate the Bullwhip Effect:

Make batches smaller. The fewer widgets that the store and the wholesaler need to buy, the less amplification occurs when orders move up the supply chain.

Improve forecasting. If all the partners in the supply chain have a better forecast, there’s less chance of ordering widgets that no one will buy.

Improve communications. If the store, the wholesaler, and the manufacturer know exactly how many widgets are being sold, they can do a better job of managing their inventories.

An important point to notice is that some of the things you should do to reduce the Bullwhip Effect might seem odd to a functional manager. In fact, they might even interfere with the objectives of your functional teams. Smaller batches, for example, are likely to increase costs for both purchasing and logistics. This is why understanding the challenges that occur every day in a holistic way is so important. Your team needs to recognize that the ways in which supply chains interact aren’t always obvious.

Supply chains are systems in which the people, processes, and technologies interact in complex ways. Managing a supply chain as a system may require taking a different approach to measuring success than what functional teams normally use.

Supply chains are systems in which the people, processes, and technologies interact in complex ways. Managing a supply chain as a system may require taking a different approach to measuring success than what functional teams normally use.

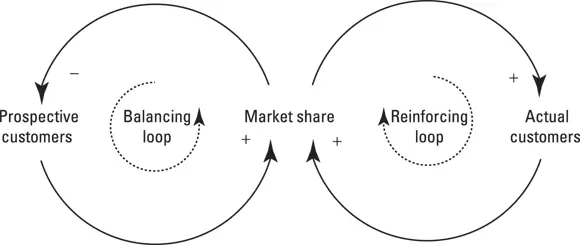

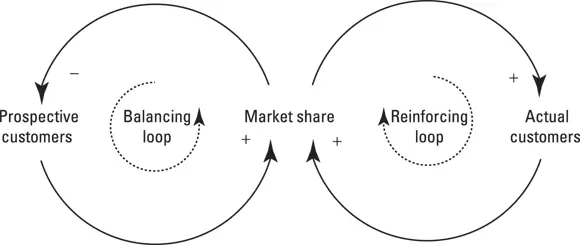

In some cases, it helps to build a model of your supply chain to show how the parts of the system interact. These models can show cause-and-effect relationships — how one thing affects another, which causes something to happen, which causes something else to happen, and so on. In other words, these models can show causal relationships. Very often, systems models reveal reinforcing loops, in which a series of events repeats over and over, getting stronger each time. Or they can show balancing loops, in which a series of events gets weaker over time.

Small events that occur in complex systems often have surprising effects, including the Law of Unintended Consequences, The Butterfly Effect, and The Cobra Effect. Understanding how systems behave can help you protect your supply chain from these outcomes.

Small events that occur in complex systems often have surprising effects, including the Law of Unintended Consequences, The Butterfly Effect, and The Cobra Effect. Understanding how systems behave can help you protect your supply chain from these outcomes.

Figure 2-4 shows a causal loop diagram, which is one of the most common tools for modeling the dynamics of a system. In this example, you see how two important supply chain dynamics affect the market share for a company. As the number of customers increases, the market share grows higher. But as the market share goes up, the number of prospective customers gets smaller because the prospects have now become customers. As the number of prospects gets smaller, the increase in market share slows and eventually stops. (For more information about supply chain modeling and simulation, see Chapter 18.)

FIGURE 2-4:Example of a causal loop diagram.

Читать дальше

Supply chains are systems in which the people, processes, and technologies interact in complex ways. Managing a supply chain as a system may require taking a different approach to measuring success than what functional teams normally use.

Supply chains are systems in which the people, processes, and technologies interact in complex ways. Managing a supply chain as a system may require taking a different approach to measuring success than what functional teams normally use. Small events that occur in complex systems often have surprising effects, including the Law of Unintended Consequences, The Butterfly Effect, and The Cobra Effect. Understanding how systems behave can help you protect your supply chain from these outcomes.

Small events that occur in complex systems often have surprising effects, including the Law of Unintended Consequences, The Butterfly Effect, and The Cobra Effect. Understanding how systems behave can help you protect your supply chain from these outcomes.