Generally, when you rank transportation methods from least expensive to most expensive, the order is this: pipeline, sea container, full truckload, less-than-truckload, and parcel.

Generally, when you rank transportation methods from least expensive to most expensive, the order is this: pipeline, sea container, full truckload, less-than-truckload, and parcel.

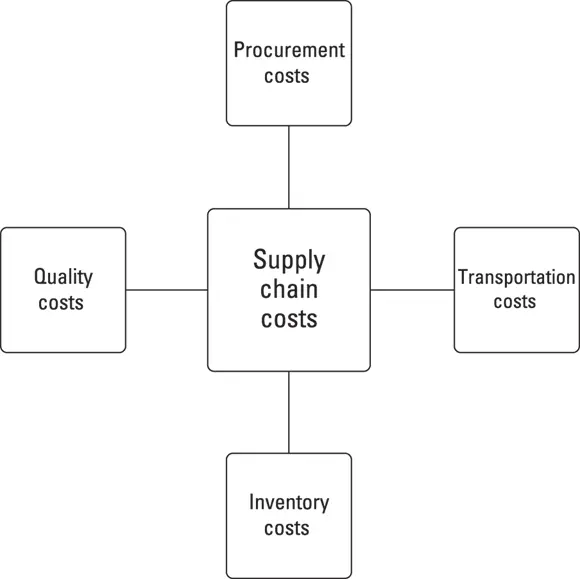

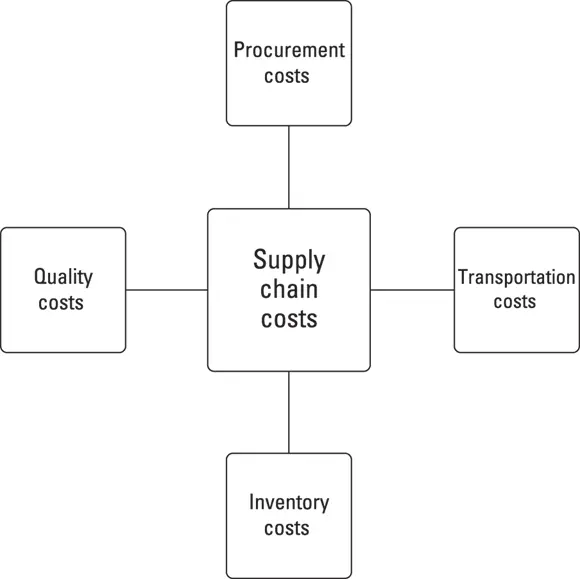

Keeping products in inventory costs money. If you’re borrowing money from the bank to pay for that inventory (which is often the case), your inventory costs you whatever interest rate you’re paying to the bank. Other costs include paying for a building to keep the inventory safe and paying people to move the inventory around inside the building. You also run the risk that products could be lost, damaged, or stolen. This problem, often called shrinkage, also creates a cost to your company. Finally, products can expire, deteriorate, evaporate, or become obsolete if they sit in a warehouse or a retail store for too long.

Any time you buy a product, you expect it to meet a certain level of quality. In some cases, you may need to have formal inspection and quality assurance processes in place to make sure that the products you receive from suppliers and the products you send to your customers meet these requirements. Any product that doesn’t meet these standards costs you money, and the more closely you have to look for quality problems, the more money you spend. Reducing the variation in manufacturing and distribution processes through techniques such as Lean and Six Sigma, which are discussed in Chapter 4, can reduce the quality costs in a supply chain.

Figure 3-2 shows that the four supply chain cost drivers are interdependent; changes in any of the buckets can affect the others.

FIGURE 3-2:Supply chain cost drivers.

Supply chain management involves making choices and trade-offs that help you maximize your profits over the long term. When you get right down to it, conflicts occur between any two functions in a business, as well as between any two businesses that work together as a part of a supply chain. Six conflicts, or trade-offs, are so common that every supply chain management professional needs to understand them and know how to manage them effectively (see Table 3-2). I discuss these trade-offs separately in the following sections.

Salespeople often say that you can’t sell a product you don’t have, and if you ask them how much product the company should make, the number is high. In other words, the salespeople want to make sure that you have enough product to meet all the customer demand that they can possibly generate, plus a little bit more. That scenario is seldom realistic.

TABLE 3-2Common Supply Chain Management Trade-Offs and Solutions

| Conflicts and Trade-Offs |

Solutions |

| Sales versus operations |

Sales and operations planning (S&OP) |

| Customer versus supplier |

Collaborative planning, forecasting, and replenishment (CPFR) |

| Engineering versus procurement |

Cross-functional teams |

| Inventory versus customer service (wholesale/retail) |

Forecasting |

| Inventory versus downtime (manufacturing) |

Lean Manufacturing |

| Procurement versus logistics |

Total cost analysis |

Meanwhile, the operations and logistics people are responsible for the costs of making, moving, and storing products. They also understand that variations in your supply chain flow cost money because you need to pay for the space and the people to meet your peak demand, even if you aren’t using that space and those people the rest of the time. Operations people want to make and store only as many products as are needed to keep manufacturing and logistics costs low.

This trade-off between sales and operations can lead to major conflicts in a company. In many cases, a sales department creates an unrealistic forecast, and the operations department is blamed for having too much inventory. In other cases, the sales department can’t meet its revenue targets because the operations team was too conservative in its production planning.

A common solution for this problem is a process called Sales and Operations Planning (S&OP) , which forces the sales and operations teams to coordinate and agree on their goals and targets.

S&OP usually starts with a sales forecast for a certain planning horizon. The sales team might estimate that it could sell 1,000 widgets per month for the next 12 months, for example. This forecast is called an unconstrained forecast because it’s based on a best-case scenario.

S&OP may sound simple, but many companies struggle to make it work. Larry Lapide of MIT is one of the leading experts on S&OP. In his article “Sales and Operations Planning Part I: The Process” in The Journal of Business Forecasting, Dr. Lapide says that these factors are required for S&OP success:

Ongoing, routine S&OP meetings

Structured meeting agendas

Pre-work to support meeting inputs

Cross-functional participation

Participants empowered to make decisions

An unbiased, responsible organization that can run a disciplined process

Internal collaborative process leading to consensus and accountability

An unbiased baseline forecast to start the process

Joint supply and demand planning to ensure balance

Support from an integrated supply-demand planning technology

External inputs to the process

To read more about the S&OP process, visit http://ctl.mit.edu/sites/ctl.mit.edu/files/library/public/article_jbf_soplanningi_lapide.pdf .

When the forecast has been established, the operations team decides whether the numbers are reasonable and what it would take to manufacture that many products. In some cases, operations may not have the staffing, the equipment, or the raw materials to make all the widgets that are called for in the unconstrained forecast. In that case, the operations team would ask the sales team to reduce its forecast based on all the constraints that have been identified. Alternatively, the operations team may need to make changes or investments that will enable them to meet the sales forecast.

S&OP is an iterative process that needs to be repeated so that the constrained sales forecast and the manufacturing production plan stay in sync. In many cases, the S&OP process involves senior executives from a company to ensure that trade-offs are understood and aligned with the corporate strategy.

Fundamentally, S&OP is about sharing information and getting people to agree on a plan. Several software companies offer S&OP tools to help the sales and operations teams automate workflows and streamline the process.

Before making an investment in S&OP software, it’s a good idea to get input from consultants who specialize in S&OP and to check out the latest product reviews from software analyst firms. Companies whose products get high marks will often provide free copies of these reports.

Before making an investment in S&OP software, it’s a good idea to get input from consultants who specialize in S&OP and to check out the latest product reviews from software analyst firms. Companies whose products get high marks will often provide free copies of these reports.

Each company in a supply chain has an effect on all the others. If your company surprises one of your suppliers with a big order, that order is likely to create problems — and cost the supplier money. But if your supplier has a pretty good idea of what you’re going to buy and when you’re going to buy it, the supplier can plan in such a way to meet your needs while keeping its own inventory and transportation costs low. In other words, everyone wins when supply chain partners collaborate and share information.

Читать дальше

Generally, when you rank transportation methods from least expensive to most expensive, the order is this: pipeline, sea container, full truckload, less-than-truckload, and parcel.

Generally, when you rank transportation methods from least expensive to most expensive, the order is this: pipeline, sea container, full truckload, less-than-truckload, and parcel.

Before making an investment in S&OP software, it’s a good idea to get input from consultants who specialize in S&OP and to check out the latest product reviews from software analyst firms. Companies whose products get high marks will often provide free copies of these reports.

Before making an investment in S&OP software, it’s a good idea to get input from consultants who specialize in S&OP and to check out the latest product reviews from software analyst firms. Companies whose products get high marks will often provide free copies of these reports.