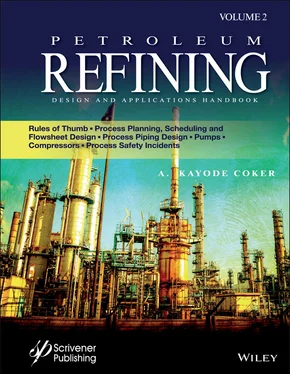

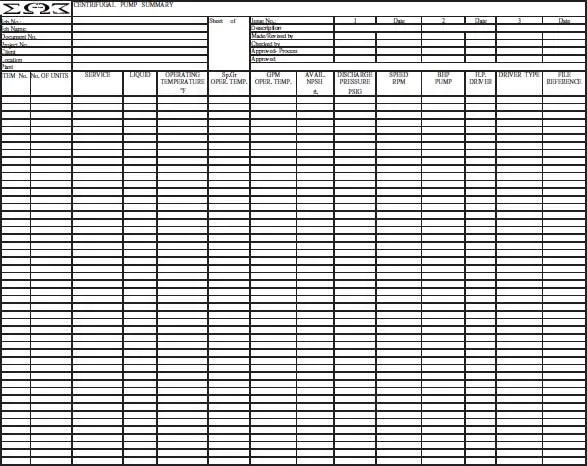

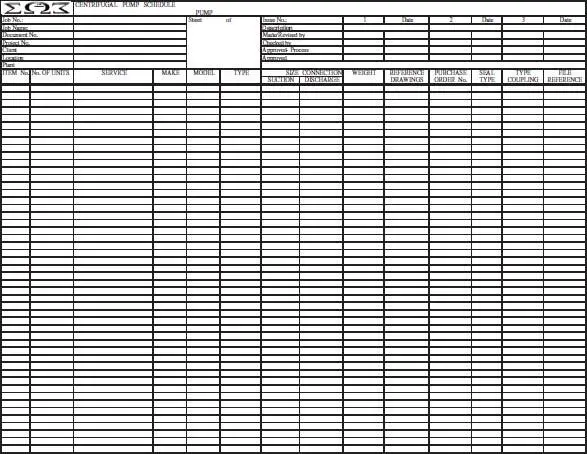

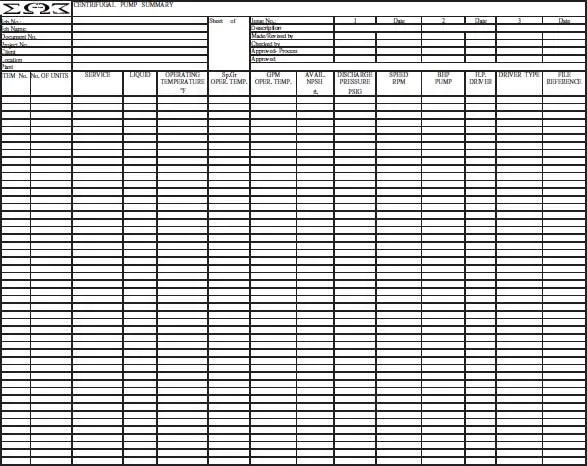

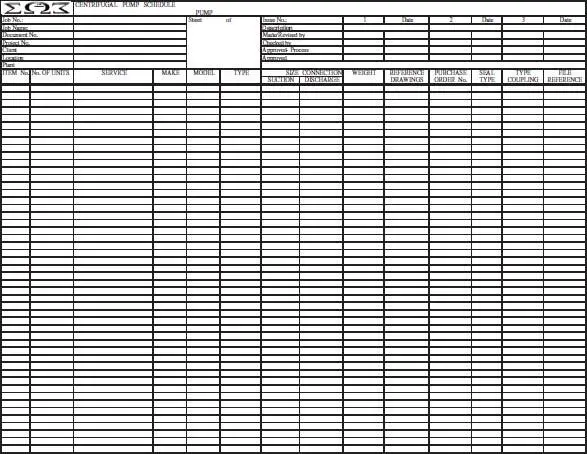

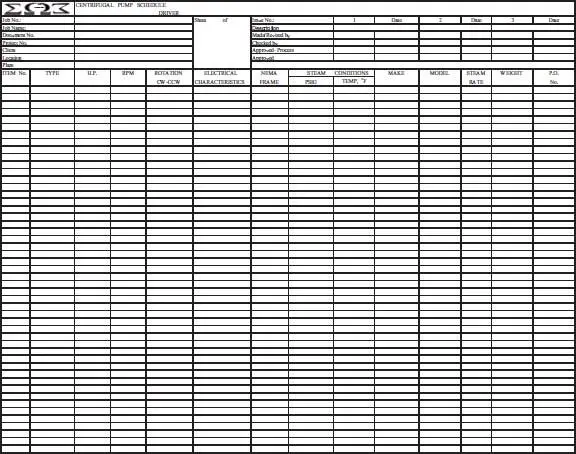

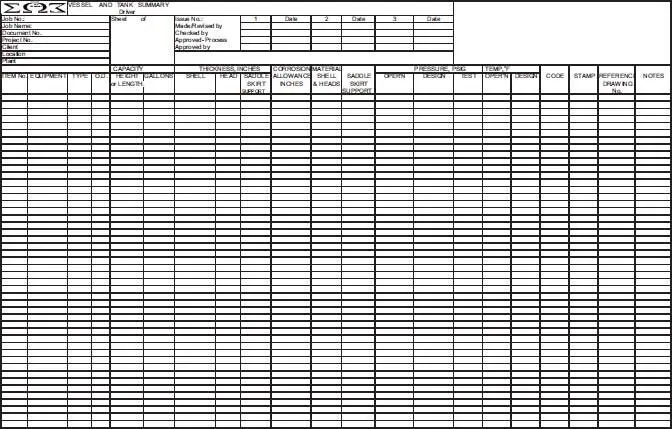

Other schedules and summaries include vessels (tanks and drums), towers or columns, heat exchangers, pumps, compressors, motors, trip, utility summary, hazardous chemicals and conditions, safety analysis table, etc. These are often developed by the process engineer for organizational uses by the process designers as well as by other engineering groups. Again, these are often cooperatively and sometimes completely prepared by a particular specialty group after interpreting and designing for the needs of the process, ( Figures 14.23– 14.28). These figures and many others (process data sheets) can be downloaded from the companion website .

Two types of schedules are in use:

1 1. The summary sheet, which summarizes process conditions and equipment selection.

2 2. The schedule sheet, which summarizes the key reference data for a particular class of equipment such as pumps, but contains no process data. The latter type is prepared for job coordination with and in the various departments, i.e., engineering, construction, purchasing, and production. It primarily serves for the construction period but, of course, does have lasting cross-reference value.

Figure 14.23 Centrifugal pump summary.

Figure 14.24aCentrifugal pump schedule.

Figure 14.24bCentrifugal pump schedule.

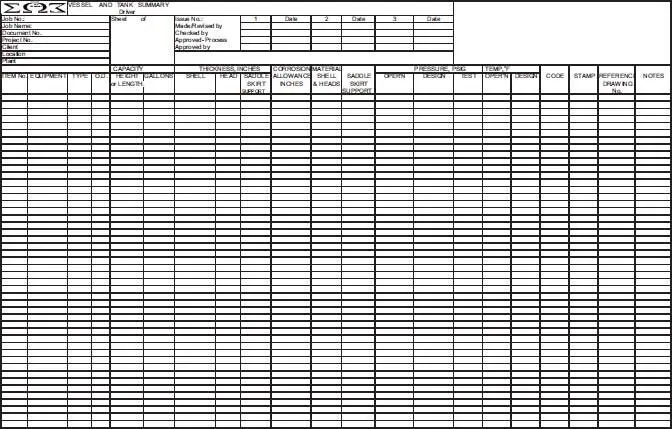

Figure 14.25Vessel and tank summary sheet.

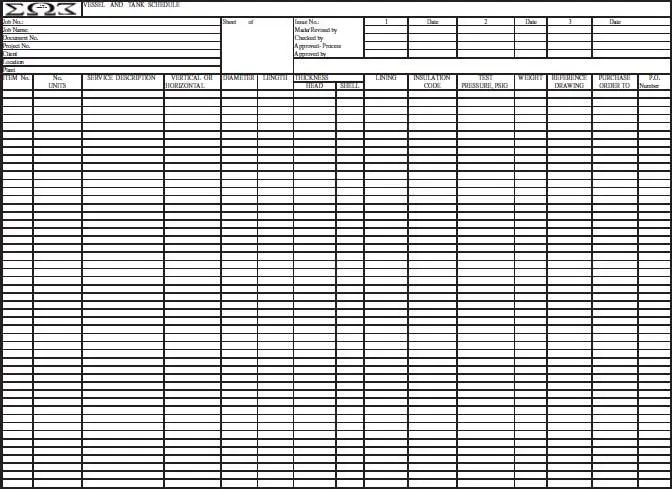

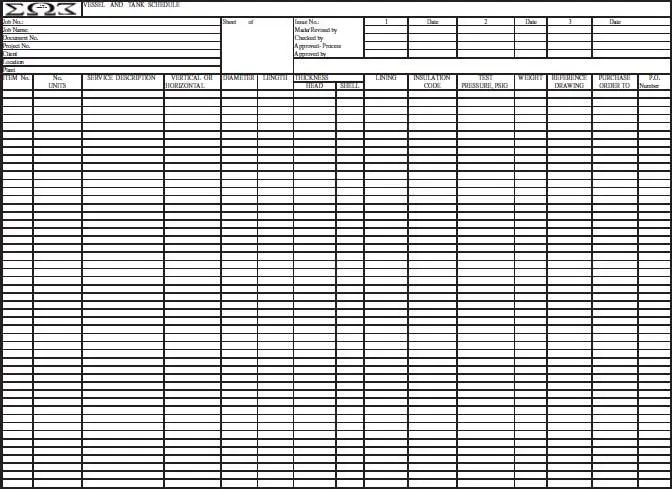

Figure 14.26Vessel and tank schedule.

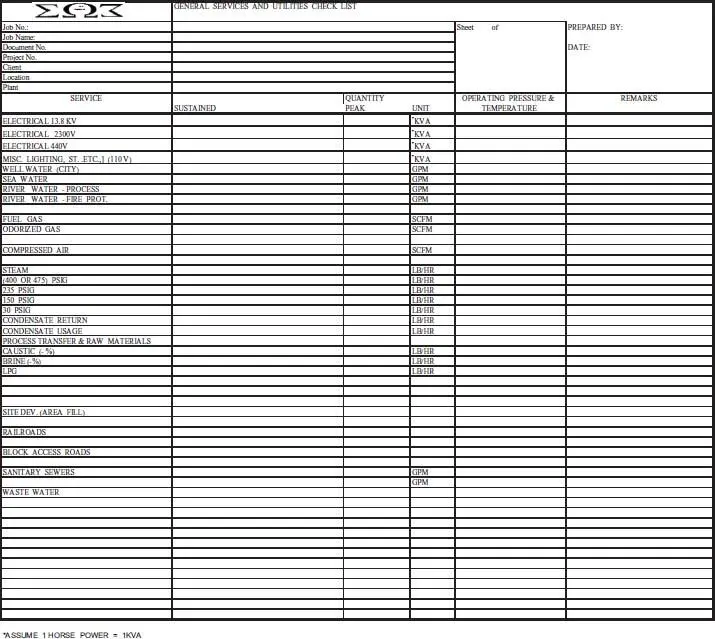

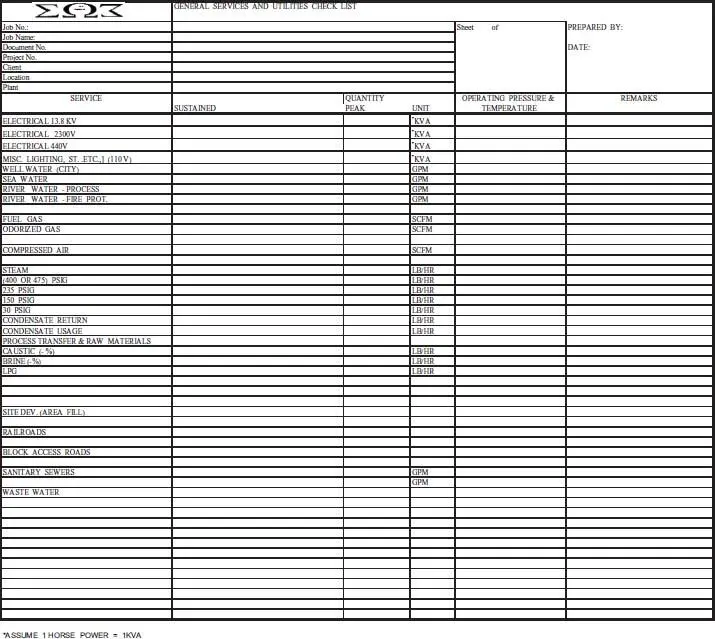

Figure 14.27 General services and utilities checklist.

From a construction viewpoint these summaries are a necessary checklist to aid in keeping the construction program organized. Individuals, who have no real knowledge of the scope of the job, and in particular the process, can properly tie the project together in the field by use of these schedules.

14.14 Information Checklists

The process engineer must summarize in some form the raw material and utility requirements for use by others. For example, the civil engineer is interested in wastewater and sanitary sewer flows for proper layout studies. He is also in need of special requirements for site development as well as railroads. The checklist of Figure 14.27is an example of a helpful form. Others can be developed to suit the project or general plant situation.

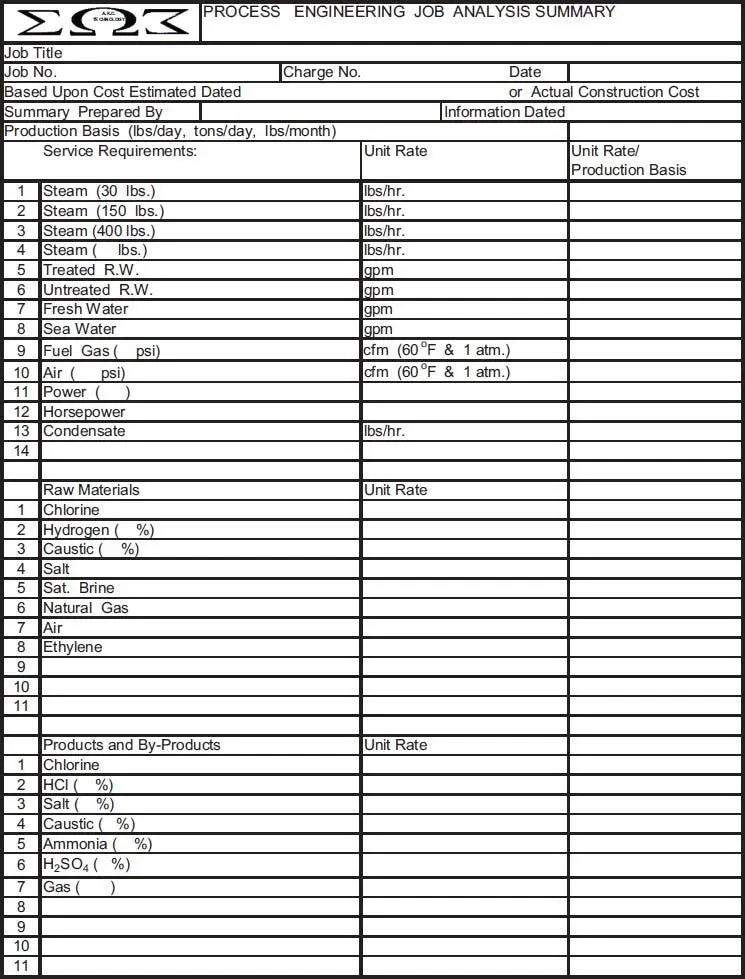

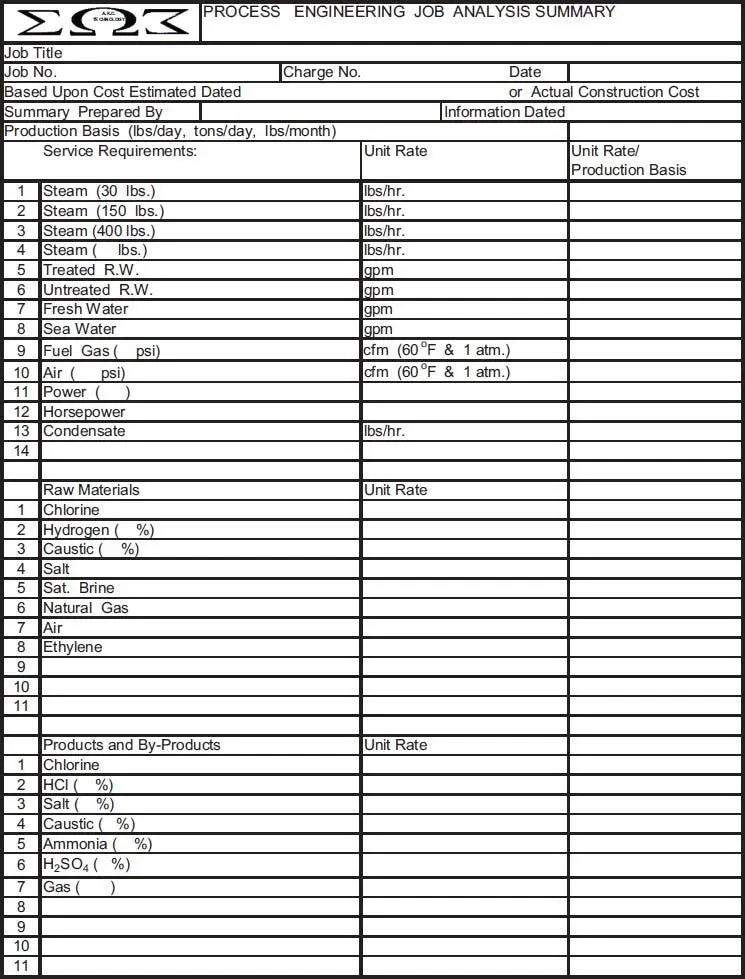

Figure 14.28 Process engineering job analysis summary.

For immediate job reference as well as for estimating requirements of a process for expansion purposes, the form shown in Figure 14.28is convenient and can be expanded to suit the process under consideration.

14.15 Basic Engineering and Front End Engineering Design (FEED)

Basic engineering or Front end engineering design is an important stage in a process design from a fundamental concept to an approved project. By the end of this stage, most of the major decisions have been arrived at, which pre-determine the overall cost of building, a facility and its operating costs. It is essential that flexibility is maintained during FEED to consider various aspects of the design and make changes quickly and accurately during this stage.

Design alternatives selected during conceptual engineering provide the basis for basic engineering in which the process design gets further defined in the form of equipment selection, definition, control schemes and cost estimates, with the objective of making decision to continue throughout the project (i.e., the Authorization for Expenditure or “AFE”). The basic engineering activity results in the FEED package, which consists of process deliverables as Process Flow Diagrams (PFD), equipment lists and data sheets, safety and hazard analysis and FEED level cost estimates. Several engineering disciplines are involved in basic engineering activity in a significantly larger team than the conceptual engineering phase. Dhole et al . [14] list several challenges that are encountered during this stage as:

Inefficient estimation process.

Collaboration barriers.

Repeatability.

Rapid loading of the detailed design systems.

Efficient estimation process.

Process flow diagrams show major equipment items, including sizes, duties, selected operating parameters, major control loops, and the process flow arrangement. The material and energy balances are also included on the process flow diagrams. Some of the safety elements that can be included on the flowsheets are:

Process materials properties.

Process conditions (e.g., pressure, temperature, composition).

Inventory.

Emergency and waste releases.

Process control philosophy.

During conceptual engineering stage, the main objective is to screen various design alternatives that ensure that an optimum design can be selected. Generally, a process engineer develops these alternatives using a process simulation tool, from which the most promising alternatives are sent on to equipment specialists to size and design the equipment. The specialist develops preliminary equipment designs and passes these to cost estimators to determine the total cost of the alternative. The sequence of tasks often takes longer than expected duration, such that the workflow slows down the overall process and limits the number of design alternatives. A consequence is that economics and sufficient heat exchanger options are not considered early, and this results in sub-optimal designs. Several simulation vendors have provided an integrated approach that provides access to equipment modeling, sizing, and economic analysis capabilities. This enables the process engineer to quickly screen several alternatives using economic analysis. This also enables the process engineer to identify critical equipment bottlenecks such as a pressure drop constraint. This approach allows the process engineer to screen alternatives in matter of hours instead of days, and the selected alternatives can be reviewed by equipment experts and cost estimates.

1. Ludwig, E. E., “Petrochemical Process Engineering”, Refining Eng., p. C-8, Mar 1960.

2. Ludwig, E. E., “Applied Project Engineering and Management”, 2nd. Ed., Gulf Publishing Co., Houston, Texas, 1988.

3. Hall, R. S., Matley, J., and K. J. McNaughton, “Current Costs of Process Equipment”, Chem. Eng., Vol. 89, No. 7, p. 80, 1982.

4. Spitzgo, C. R., “Guidelines for Overall Chemical Plant Layout”, Chem. Eng., Vol. 83, No. 20, p. 103, 1976.

Читать дальше