Self-Healing Smart Materials

Здесь есть возможность читать онлайн «Self-Healing Smart Materials» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Self-Healing Smart Materials

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 80

- 1

- 2

- 3

- 4

- 5

Self-Healing Smart Materials: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Self-Healing Smart Materials»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Self-Healing Smart Materials — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Self-Healing Smart Materials», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

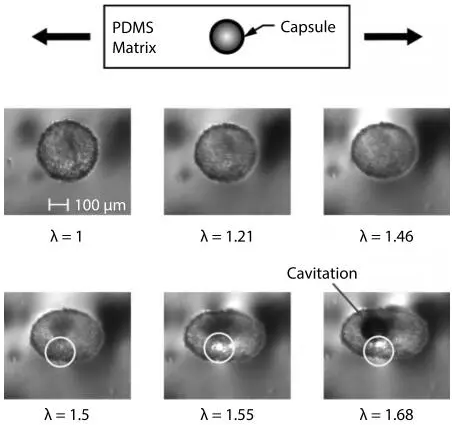

However, some shortcomings of the DCPD-Grubbs catalyst systems (low long term stability due to possible side reactions with air and the polymer matrix) [27], encouraged the search for other chemistries that could overcome these difficulties. The condensation of hydroxy capped polydimethylsiloxane (HOPDMS) and polydiethoxysiloxane (PDES) with dibutyltindilaurate (DBTDL) in a vinyl ester matrix showed an improved stability, but the healing efficiencies were rather poor [27]. Much better results were observed for a polydimethylsiloxane (PDMS) elastomer filled with poly(urea-formaldehyde) (UF) microcapsules containing the same precursor and Pt initiator used to synthesize the PDMS matrix separately [28]. The authors studied the breaking mechanism of the capsule, and provided an interesting insight from the observation of the process of deformation and failure of a microcapsule within the elastomeric matrix. The sequence is shown in Figure 1.3. For stretch values below 1.5 the micro-capsule is deformed along with the matrix, withstanding the stress, but for higher deformations, the failure of its wall releases the chemical precursors. This study focused on some very important aspects of the use of microcapsules for self-healing composites, such as the microcapsule rupture process, and how its presence affects some properties of the matrix. It clearly showed that the breaking of the capsules is a quite complex matter, and even brittle materials (when evaluated in bulk) such as UF may need relatively high strain values to fail [28, 29]. The authors also observed an improvement on tear strength with the increase in the microcapsules concentration (up to 20 wt% of microcapsules), which is in agreement with previous results for reinforced PDMS [30, 31]. To ease the flow of the healing agent off the microcapsules and into the crack, its viscosity was reduced by using heptane as diluent [28]. Using a similar system, consisting in a silanol-terminated polydimethylsiloxane (STP) as healing agent and dibutyltin dilaurate (DTDL) as catalyst, Kim et al. obtained a self-healing coating that could repair itself at temperatures as low as −20 °C. The viscoelastic material produced by the healing agent was capable of protecting the coated and scratched specimens from saline solution uptake upon immersion for 48 h at −20 °C [32].

Figure 1.3Images of a single PDMS microcapsule subjected to uniaxial tension at different values of deformation (γ). Reprinted with permission from Ref. [28]. Copyright (2007) John Wiley & Sons, Inc.

Microencapsulated epoxy precursors were also applied as external healing agent in matrices with a dispersed latent initiator [33–37]. Yin et al. utilized UF microcapsules containing an epoxy resin based on diglycidyl ether of bisphenol A (DGEBA), and a latent catalyst consisting in a complex of CuBr 2and 2-methylimidazole (MeIm), dispersed in the matrix [33]. Their results showed very good healing efficiencies, with healed specimens showing fracture toughness values 11% higher than those of the virgin samples. As the authors explained, this is a side effect of the higher fracture toughness of the resin used as healing agent when compared to the matrix, probably due to the higher temperature and/or the different curing mechanism of the healing reaction: the samples were synthesized at temperatures up to 100 °C, and the subsequent healing was performed at 130 °C. They also applied the self-healing matrix to the synthesis of self-healing epoxy laminates, using glass fibers [33, 34]. However, the healing efficiencies were lower in this case, and an important downside of the use of microcapsules was the reduction of the tensile properties for microcapsule loads above 30 wt% [34]. Guadagno et al. assessed the healing efficiency and the mechanical properties of self-healing epoxy systems with different flexibilizers [36, 37]. When the curing temperature of these systems was raised from 170 to 180 °C, the mechanical moduli increased, but the healing efficiency slightly decreased, probably due to an initial thermolytic decomposition of the Hoveyda–Grubbs’ first generation catalyst. Interestingly, the replacement of the Heloxy71 used as flexibilizer by the reactive diluent 1,4-butanedi-oldiglycidylether (BDE) leads to an increase in the compressive modulus, from around 0.7 to 1.4 GPa, with no loss in the healing efficiency (above 80%) [37]. Hia et al. demonstrated multiple self-healing ability in epoxy composites with alginate multicore microcapsules [38]. Three to four healing cycles were produced, though the efficiencies were around 55%, which are lower than for other systems. Moreover, the authors found that self-healing specimens have lower impact strength than the neat epoxy polymers, due to the large size of the capsules, and its high load.

Polyurethanes (PU) were explored for extrinsic self-healing systems [39, 40]. He et al. used isophorondiisocyanate (IPDI) encapsulated into polyurea capsules as self-healing agent for PU matrices and also for epoxy-based ones [41]. They show that complete healing (efficiencies around 100%) of both epoxy and PU matrices is achieved for capsules with diameters of 96 mm or higher. Smaller capsules produced poorer healing performances. Gil et al. used microencapsulated diisocyanate to improve the tensile strength of collagen [42]. They used two different diisocyanates: IPDI and 4,4’-diphenylmethane diisocyanate (MDI); the isocyanate groups react with the collagen, creating new crosslinks and mending the damages. Other healing agents employed for extrinsic self-healing coatings, including thiol-ene and azide-alkyne precursors, as well as vinyl ester and unsaturated polyesters have also been tested, as pointed out in a review by Hillewaere and Du Prez [43].

A smart approach proposes to develop self-healing systems especially designed so that the healing can be activated by the environment surrounding the material when a crack propagates. Different research groups used encapsulated isocyanate that reacts with water when released into aqueous environments, producing coatings with potential applications in offshore and other marine devices. Di Credico et al. also used encapsulated IPDI to provide self-healing capacity to a DGEBA-based epoxy matrix, thanks to the crosslinking reaction of isocyanate with the surrounding water [44]. Figure 1.4-I shows the damaged coating, and the healed coating after immersion for 48 h in salty water. The authors emphasized that the rough outer surface of the microcapsules played a key role improving the adhesion to the matrix, allowing the capsule to fail and release the IPDI. Wang et al. also used IPDI as healing agent to repair cracks in an alkyd varnish coating (AVC) [45]. Figure 1.4-II shows the aspect of the mended scratch on different substrates after different times of exposure to marine salty water. Though some seawater could penetrate into the coating and reach the substrate, the self-healing prevented a much larger damage.

Light is another possible external stimulus that can be harnessed to trigger the healing response. Sunlight was proposed by some authors to induce the self-healing of polymeric coatings. Song et al. designed the first photoinduced microcapsule-based self-healing coating from tetraethyl ortosilicate and a polysiloxane, with encapsulated methacryloxypropylterminated polydimethylsiloxane (MAT-PDMS) and benzoinisobutyl ether (BIE) photoinitiator [46]. The conversion of the healing agent upon exposure to real sunlight was somewhat lower than when an artificial UV light was used instead. However, several tests (optical and SEM examination, and measurements of water uptake and chloride ion penetration) showed that relatively short times (4 h) of sunlight exposition are enough to produce an acceptable healing. Figure 1.5 shows the results obtained, comparing the performance of the self-healing coating with the control coating (without the encapsulated healing agent). Khalaj Asadi et al. successfully encapsulated a sunlight curable silicon based resin, and studied several parameters affecting some final properties of the capsules [47]. They used polyvinylpyrrolidone as emulsifier, and established the optimum amount to obtain higher yields. These capsules showed good resistance to water and xilene, but ethanol produced a rapid deterioration of the microcapsules. The authors remarked that these microcapsules can be readily used for self-healing polymers formulations.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Self-Healing Smart Materials»

Представляем Вашему вниманию похожие книги на «Self-Healing Smart Materials» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Self-Healing Smart Materials» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.