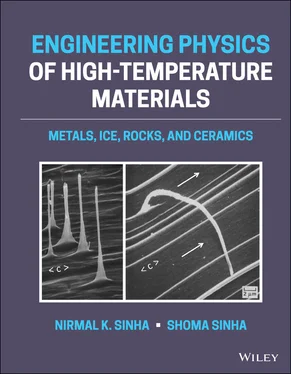

1 Cover

2 Title Page Engineering Physics of High‐Temperature Materials Metals, Ice, Rocks, and Ceramics Nirmal K. Sinha Retired, Institute for Aerospace Research, National Research Council of Canada, Ottawa, Ontario, Canada and Shoma Sinha Queen's Partnerships and Innovation, Queen's University, Kingston, Ontario, Canada

Metals, Ice, Rocks, and Ceramics

3 Copyright Page

4 Dedication

5 Acknowledgments

6 Engineering Physics of High‐Temperature MaterialsPreface

7 1 Importance of a Unified Model of High‐Temperature Material Behavior 1.1 The World's Kitchens – The Innovation Centers for Materials Development 1.2 Trinities of Earth's Structure and Cryosphere 1.3 Earth's Natural Materials (Rocks and Ice) 1.4 Rationalization of Temperature: Low and High 1.5 Deglaciation and Earth's Response 1.6 High‐Temperature Deformation: Time Dependency 1.7 Strength of Materials 1.8 Paradigm Shifts References

8 2 Nature of Crystalline Substances for Engineering Applications 2.1 Basic Materials Classification 2.2 Solid‐state Materials 2.3 General Physical Principles 2.4 Glass and Glassy Phase 2.5 Rocks: The Most Abundant Natural Polycrystalline Material 2.6 Ice: The Second Most Abundant Natural Polycrystalline Material 2.7 Ceramics 2.8 Metals and Alloys 2.9 Classification of Solids Based on Mechanical Response at High Temperatures References

9 3 Forensic Physical Materialogy 3.1 Introduction 3.2 Polycrystalline Solids and Crystal Defects 3.3 Structure and Texture of Natural Hexagonal Ice, I h 3.4 Section Preparation for Microstructural Analysis 3.5 Etching of Prepared Section Surfaces 3.6 Sublimation Etch Pits in Ice, I h 3.7 Etch‐Pitting Technique for Dislocations 3.8 Chemical Etching and Replicating of Ice Surfaces 3.9 Displaying Dislocation Climb by Etching 3.10 Thermal Etching: An Unexploited Materialogy Tool References

10 4 Test Techniques and Test Systems 4.1 On the Strength of Materials and Test Techniques 4.2 Static Modulus and Dynamic Elastic Modulus 4.3 Thermal Expansion Over a Wide Range of Temperature 4.4 Creep and Fracture Strength 4.5 Bending Tests 4.6 Compression Tests – Uniaxial, Biaxial, and Triaxial 4.7 Tensile and/or Compression Test System 4.8 Stress Relaxation Tests (SRTs) 4.9 Cyclic Fatigue 4.10 Acoustic Emission (AE) and/or Microseismic Activity (MA) 4.11 Tempering of Structural and Automotive Glasses 4.12 Specimen Size and Geometry: Depending on Material Grain Structure 4.13 In Situ Borehole Tests: Inspirations from Rock Mechanics References

11 5 Creep Fundamentals 5.1 Overview 5.2 On Rheology and Rheological Terminology 5.3 Forms of Creep and Deformation Maps 5.4 Grain‐Boundary Shearing or Sliding 5.5 Creep Curves – Classical Primary, Secondary, and Tertiary Descriptions 5.6 Phenomenology of Primary Creep in Metals, Ceramics, and Rocks 5.7 Primary Creep in Ice: Launching SRRT Technique and EDEV Model 5.8 Grain‐Boundary Shearing (gbs) and Grain‐Size Dependent Delayed Elasticity 5.9 Generalization of EDEV Model: Introduction of Grain‐Size Effect 5.10 Logarithmic Primary Creep: An Alternative Form of the EDEV Model 5.11 Shifting Paradigms: Emphasizing Primary Creep of Polycrystalline Materials 5.12 SRRT for Primary Creep and EDEV Model of a Titanium‐Base Superalloy (Ti‐6246) 5.13 SRRT for Primary Creep and EDEV Model for a Nickel‐Base Superalloy (Waspaloy) 5.14 SRRT for Primary Creep of a Nickel‐Rich Iron‐Base Alloy (Discaloy) 5.15 SRRTs for Primary Creep and EDEV Model of a Nickel‐Base Superalloy (IN‐738LC) 5.16 EDEV‐Based Strain‐Rate Sensitivity of High‐Temperature Yield Strength 5.17 Single‐Crystal (SX) Superalloy Delayed Elasticity and γ / γ ′ Interface Shearing 5.18 Creep, Steady‐State Tertiary Stage, and Elasto–Viscous (EV) Model for Single Crystals 5.19 Creep Fracture and EV Model for CMSX‐10 SXs 5.20 Fracture and Inhomogeneous Deformation 5.21 Dynamic Steady‐State Tertiary Creep of Several Nickel‐Base SXs References

12 6 Phenomenological Creep Failure Models 6.1 Creep and Creep Failure 6.2 Steady‐State Creep 6.3 Commonly Used Creep Experiments and Strength Tests 6.4 Modeling Very Long‐Term Creep Rupture from Short‐Term Tests 6.5 High‐Temperature Low‐Cycle Fatigue (HT‐LCF) and Dwell Fatigue 6.6 Crucial Tests on Rate Sensitivity of High‐Temperature Strength 6.7 Rational Approach Inspired by the Principle of “Hindsight 20/20” References

13 7 High‐Temperature Grain‐Boundary Embrittlement and Creep 7.1 Fracture and Material Failure 7.2 Grain Size Effects on Strength 7.3 Grain‐Boundary Shearing (gbs) Induced Crack Initiation References

14 8 Microstructure and Crack‐Enhanced Elasto – Delayed‐Elastic – Viscous Models 8.1 Physics‐Based Holistic Model Approach 8.2 Kinetics of Microcracking and Structural Damage 8.3 Microcrack‐Enhanced EDEV Model 8.4 EDEV‐Based Algorithm for Constant Strain Rate, Encompassing Cracking 8.5 Constant Stress, Crack‐Enhanced Creep: EDEV Predictions 8.6 Cyclic Fatigue 8.7 Crack Healing or Closure of w‐Type Voids Generating r‐Type Cavities References

15 9 Stress Relaxation at High Temperatures 9.1 The Role of Stress Relaxation Tests at High Temperatures 9.2 Constitutive Equations without Effect of Grain Size 9.3 Temperature and Grain‐Size Effects on SR 9.4 Forecasting Grain‐Size Effects on SR in Pure Ice Based on EDEV Equation 9.5 High‐Temperature Forming, Delayed Spring‐Back, and Grain‐Size Effects on SR in Metals References

16 10 Ice Age and Intraglacial Depression and Postglacial Rebound of Earth's Crust 10.1 Tectonic Plates, Lake Ice, and High‐Temperature Materials: What Is the Connection? 10.2 On Glaciers and Oceanic Ice Cover: Past and Present 10.3 Dow's Lake Studies 10.4 Elasto–Delayed‐Elastic (EDE) Theory for Plates References

17 11 Plate Tectonics and Polar Sea Ice 11.1 Retrospective Introduction 11.2 Earth and Plate Tectonics 11.3 Scale of Observations 11.4 Vertical Temperature Profiles of Earth and Ice Sheet 11.5 Time–Temperature Shift Function 11.6 Nonlinear, Grain‐Size‐Dependent Delayed Elasticity (Anelasticity) of Mantle 11.7 Stress Field of Earth's Crust 11.8 Koyna and Warna Dams in India and Reservoir‐Triggered Seismicity (RTS) 11.9 Movement of Tectonic Plates, Indentation, and Fracture 11.10 Looking Forward References

18 Index

19 End User License Agreement

1 Chapter 2 Table 2.1 Comparison of the properties of some basic carbon allotropes. Table 2.2 Nominal chemical compositions (wt. %) of Nimonic 90 (Betteridge a...

2 Chapter 5Table 5.1 Material parameters for ice (S‐2 and equiaxed)), Ti‐6246, Waspalo...

3 Chapter 7Table 7.1 Creep parameters for pure S‐2 ice obtained independently from cre...

1 f05 Figure P.1 Delayed elastic strain (des) recovery. (a) constant‐stress creep ... Figure P.2 “Trishul” (trident) of the two primary – North (N) and South (S) ...

2 Chapter 1 Figure 1.1 Harappan style of brick production from clay. (a) Process of sun ... Figure 1.2 Melting points of some pure metals and ice. Figure 1.3 Scanning electron micrograph of (a) a vertical section of a brine... Figure 1.4 Short‐term (200 s) and longer‐term (2341 s) tensile SRRTs on a si... Figure 1.5 Results of Figure 1.4 shown in a logarithmic timescale, illustrat... Figure 1.6 Strain–time curves, showing rise time to apply full load (<1 s), ... Figure 1.7 Stress–strain diagram. (a) Two values of elastic modulus, E , and ... Figure 1.8 Stress dependence of average viscous strain rate during primary c...

3 Chapter 2 Figure 2.1 Basic crystal lattice structures: (a) BCC, (b) FCC, and (c) HCP c... Figure 2.2 Stacking sequence in (a) FCC and (b) HCP crystals. Figure 2.3 Typical pressure versus temperature of a one‐component system.

Читать дальше