1 ...6 7 8 10 11 12 ...31

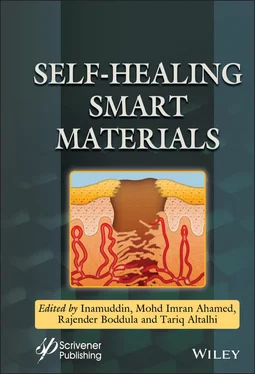

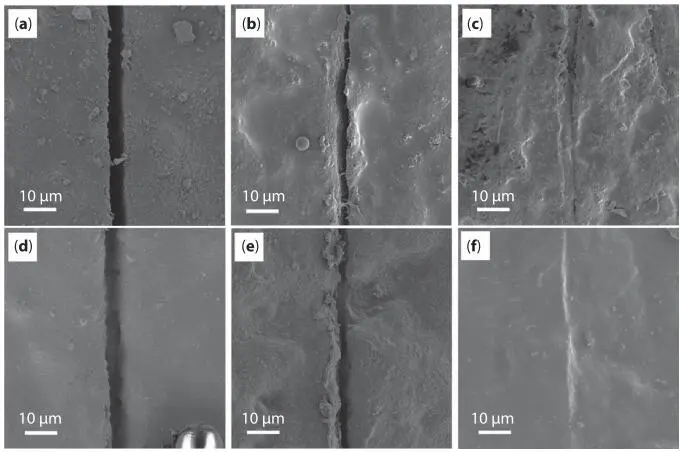

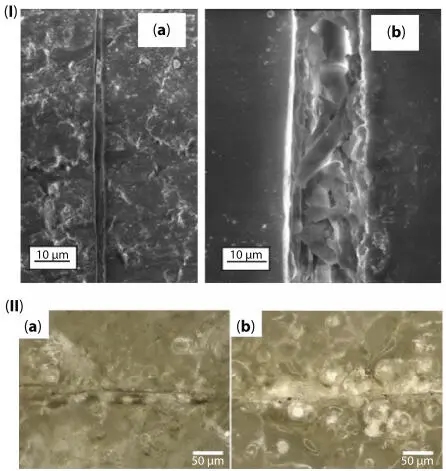

Figure 1.4(I)—SEM micrographs of crack in a coating with PU/PUF microcapsules (a) before and (b) after immersion in salt water for 48 h. Reprinted from Ref. [44]; Copyright (2013) with permission from Elsevier. (II)—Alkyd varnish coatings on a titanium surface after 200 and 1,200 h of seawater immersion. Reprinted from Ref. [45] with permission from The Royal Society of Chemistry.

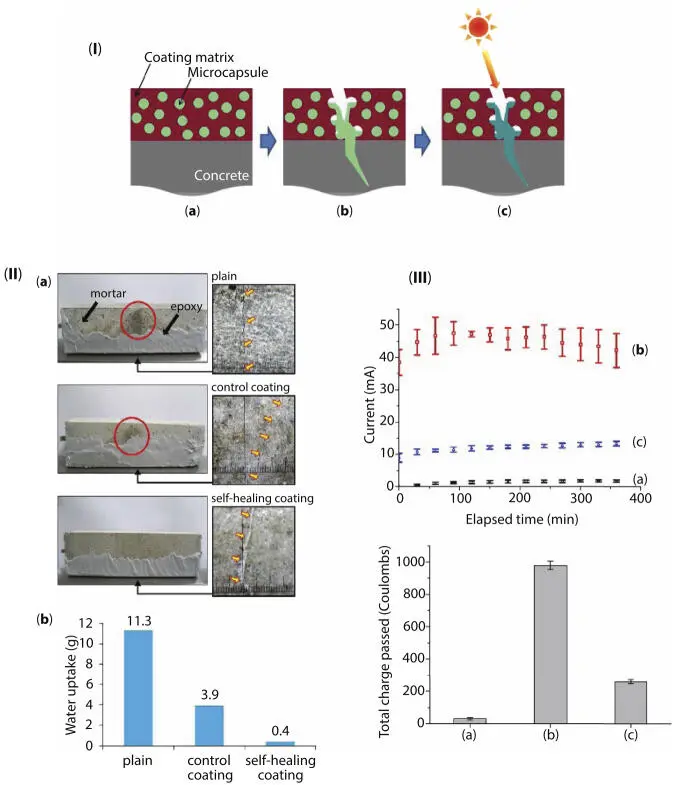

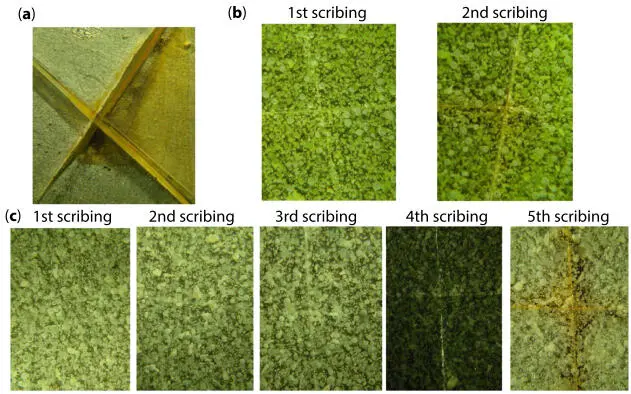

The use of UV light to trigger the mending reactions was explored as well by other researchers. Gao et al. encapsulated a photosensitive resin obtained from a mixture of Bisphenol A epoxy resin diacrylate ester (BAEA) and trimethylolpropane-triacrylate (TMPTA) with 1-hydroxy-cyclohexyl-phenyl-ketone into UF capsules, and embedded them into an epoxy-amine matrix [48]. The microcapsules were synthesized containing TiO 2in its shell in order to absorb the UV light and protect the photosensitive resin into the undamaged capsules from curing before being released. Anticorrosion tests were performed after scratching the samples and healing during 30 s with UV irradiation. The neat epoxy-amine matrix and a composite with capsules without TiO 2were used as control (CC1 and CC2 respectively). Corrosion was observed in CC1, but CC2 and the self-healing coating could protect the steel substrate. When the experiment was repeated with a new scratch on the same samples, CC2 could no longer protect the steel, and corrosion was observed. Figure 1.6 shows the images of the samples after each test. For the self-healing coatings, the experiment was repeated 5 times, and the self-healing ability was eventually lost after 5 irradiation events. SEM images of the scratch and the electric current measured for each case confirmed the previous observations.

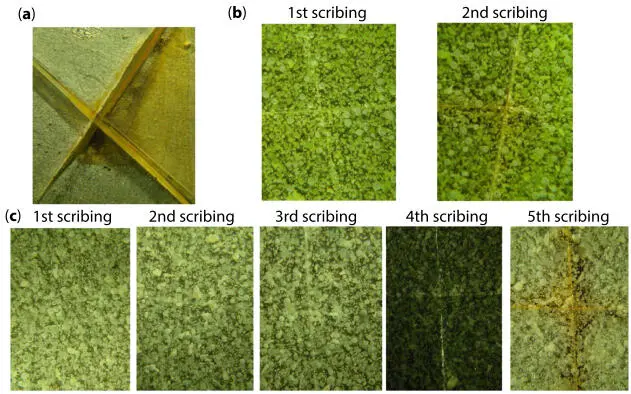

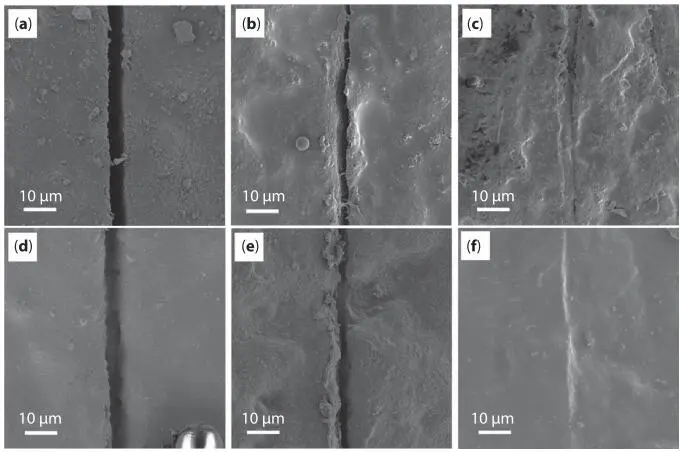

Zhu et al. also used a UV-curable healing agent into microcapsules with a rapidly degradable inner polymeric shell and an outer TiO 2shell that can absorb UV radiation [49]. The action of the TiO 2shell helps to degrade the inner shell, releasing the healing agent. Hence, the self-healing composite displays a dual release mechanism that enhances its efficiency. The micro-encapsulated healing agent consisted in an epoxy silicone with a photosensitive initiator (triarylsulfonium hexafluorphosphate salt) and the matrix was based in silicone resins. Figure 1.7 shows a scratch on the coatings after 12 h of UV irradiation. The comparison was made using composites with microcapsules without the healing agent (labeled as “BS-xx”), and composites prepared with capsules filled with the healing agent but unable to fail and release it by UV irradiation, due to a low concentration of TiO 2NPs in its outer shell (labeled as “CS-xx”). The self-healing coatings were labeled as “SH-xx”. The numbers xx represent the wt% of microcapsules. The effect of the healing agent released within the crack is very clear, and for a microcapsules load of 60 wt% the healing seems to be excellent.

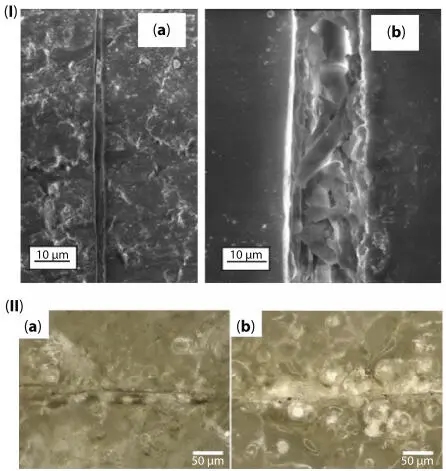

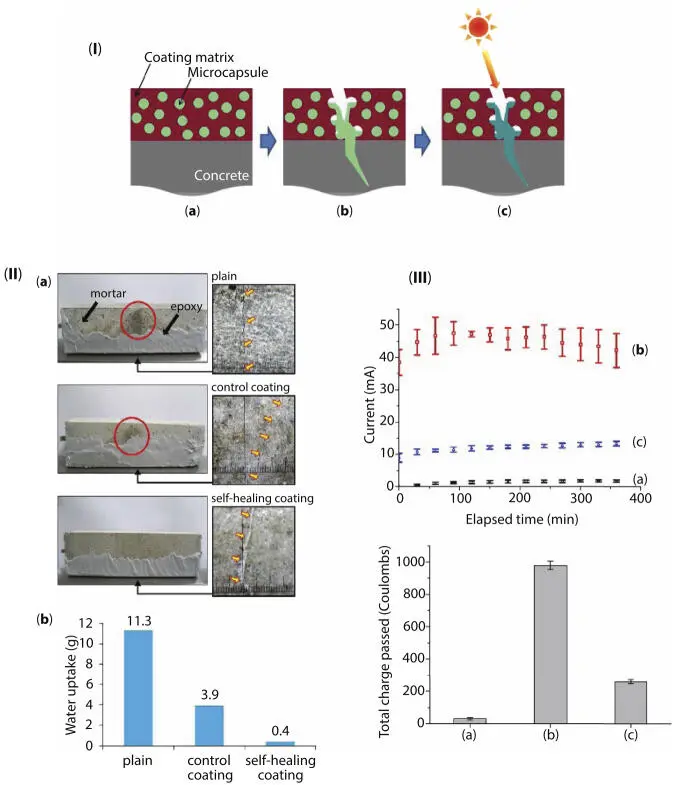

Figure 1.5(I)—Scheme of the sunlight induced healing mechanism: the crack breaks the microcapsules and release the healing agent, which undergoes the crosslinking reaction upon exposure to sunlight. (II)—Water uptake measurements for the plain mortar, and mortars coated with the control and the self-healing coating. (III)—Chloride penetration tests. Current vs. elapsed time, and accumulated charge during 6 h for the undamaged control coating (a), scribed control coating (b) and scribed and healed self-healing coating (c). Reprinted with permission from Ref. [46]. Copyright (2013) American Chemical Society.

Figure 1.6Steel substrates coated with (a) CC1, (b) CC2 and (c) self-healing coating, after successive scribing and healing sequences. Reprinted with permission from Ref. [48]; Copyright (2015) American Chemical Society.

Some drawbacks of the use of microcapsules/hollow microfibers are worth to mention. Samadzadeh et al. [50] have mentioned some of them, including the negative side effects on the mechanical properties of the material, such as Young’s modulus and ultimate stress [50, 51]. Adhesive properties can also suffer a decrease due to the presence of microcapsules [50]. In most cases a compromise between an acceptable healing with a minor deterioration of the resistance has to be reached. Additionally, there are some aspects that should not be overlooked when designing a self-healing composite based on the dispersion of microcapsules with a healing agent in a polymeric matrix. The adhesion between the capsule and the matrix plays a very important role, since it is directly related with the load transfer to the microcapsule, and to its ability to release the healing agent [22, 49]. Another disadvantage is that once the healing agent has been consumed in one or multiple repairing events, the material loses its self-healing feature. This last disadvantage is one of the most important differences in comparison with intrinsic self-healing systems, as we will show in the next section.

Figure 1.7SEM images of the scratch of (a) BS-55, (b) CS-55, (c) SH-55, (d) BS-60, (e) CS-60, and (f) SH-60 after 12 h of UV irradiation (wavelength: 310 nm; power: 582 W/m2). Reprinted with permission from Ref. [49]. Copyright (2019) American Chemical Society.

1.3 Intrinsic Self-Healing Polymer Coatings

The expression intrinsic self-healing polymers designates a wide variety of systems with autonomous or induced healing ability. A large portion of them are polymeric networks with either reversible or dynamic bonds, and are nowadays the most relevant kind of intrinsic self-healing thermosetting polymers with potential use as coatings. The use of reversible H-bonds to prepare self-healing supramolecular polymers received a great impulse following the first report of the synthesis and use of 2-ureido-4[1H]-pyrimidinone (UPy) for that end [52, 53]. UPy is a functional group that associates through a quadruple H bonding, displaying an unprecedented high association constant (Figure 1.8-I). It can be introduced in the main chain or in pendant ones of linear or branched polymers with different chemistries, and since its development by Sijbesma et al. [52] it has been used in multiple polymers with different applications, including self-healing coatings [54–56]. This versatility, that allows the introduction of UPy groups in a number of polymeric backbones, is one of its most important advantages. The high association constant provides good mechanical strength at low temperatures, but at high temperatures the constant drops dramatically, allowing the mending of the material, as shown in Figure 1.8-II. Leibler et al. developed self-healing supramolecular rubbers by using different multiple hydrogen bonding groups [57–59]. They used a mixture of fatty diand trifunctional carboxylic acids condensed with diethylene triamine and afterwards reacted with urea to yield oligomers bearing H bonding groups with different functionalities that performed the same function as UPy, achieving self-healing even at room temperature [60].

Читать дальше