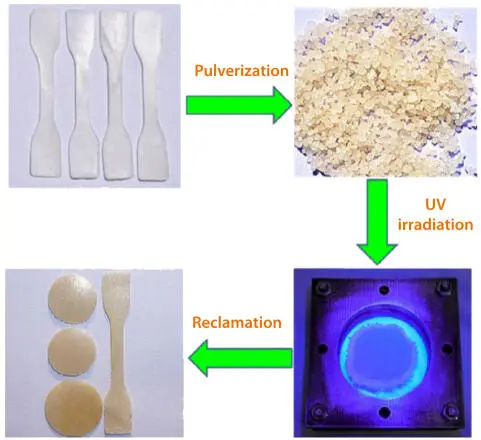

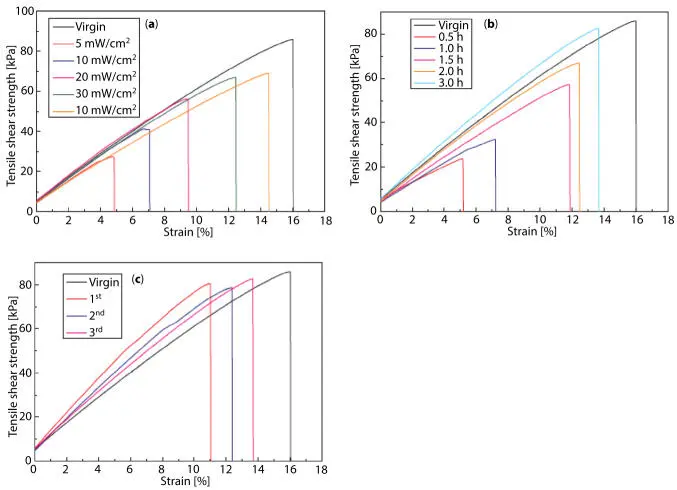

Given the outstanding obtained results, the authors advanced in applying the optimum self-healing protocol (30 mW/cm 2, 3 h) in a grounded sample of the B1S10 compound in order to reprocess it and enabling to obtain a material with a different shape as is schematized in Figure 3.16. The recycle efficiency (the recovery degree in the mechanical properties after one treatment) decreases with the process: an efficiency of 82% is obtained when the reclamation is made once, but diminishes up to 64% after the third reclamation cycle. This process also depends on the mesh size due to when the particle is smaller the available surface to react is higher.

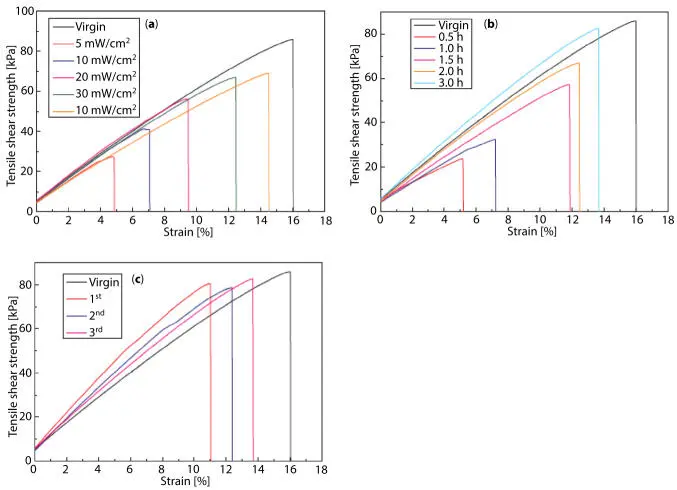

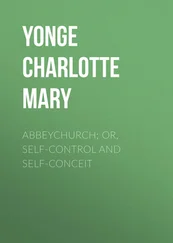

Figure 3.15Tensile strain measurements to characterize the self-healing process induced by UV-radiation varying the following conditions: (a) intensity, (b) interval time. (c) Repeated self-healing when the sample was irradiated with 30 mW/cm2 during 3h (Adapted with permission from Xiang et al . [54]).

Figure 3.16Process followed to the sample reclamation (Adapted with permission from Xiang et al . [54]).

The principal characteristics of bromobutyl rubber (BIIR) are its high air impermeability and resistance to chemical agents. BIIR is obtained from bromination of butadiene rubber, enhancing the reactivity with amines and, therefore, allowing various functionalities to BIIR.

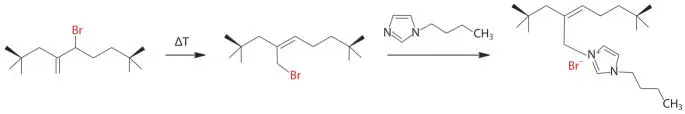

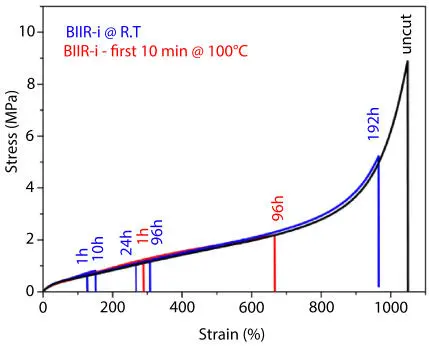

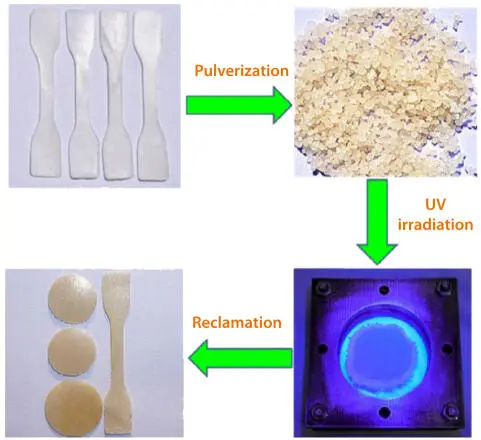

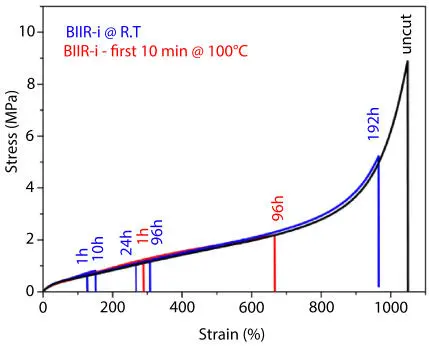

The above mentioned mechanism was used by Das et al. to introduce ionic functional groups in a rubber compound by using butylimidazole to increases the ionic interaction with the aim to enhance the self-healing, without no extra cross-links agent required [55]. Authors compounded BIIR and butylimidazole in an internal mixer to form amidazolium bromide groups (Figure 3.17), previously an isomerization of the bromide group is induced to obtain the reactive species. Then, the elastomer network is produced by ionic crosslinking and the obtained samples are soluble, which can be seen as an advantage from the environmental point of view. The crosslinking reaction was characterized in a rheometer at temperatures between 80 and 160 °C during 1 h. The highest modulus values were obtained at 100 °C, and it was found that at higher temperatures the modulus decreases, indicating the weakness of the ionic interactions at elevated temperatures. The self-healing behavior was observed through stress–strain measurements on cut samples, which were allowed to heal at different times: at room temperature during 1, 10, 24, 96 and 196 h and to explore a faster healing the cut and restored sample was maintained at 100 °C for the first 10 min of the total time. It was found that the healing effect increases with time and the obtained stress–strain curves are similar to that one from the uncut sample, as can be seen in Figure 3.18. A good self-healing is obtained due to the reversible characteristic of the ionic bonds and to the good mobility of the isobutylene chains (which is improved at higher temperatures). They did not obtain self-healing in the compound crosslinked with sulfur.

Figure 3.17Reaction scheme for the conversion of BIIR with butylimidazole for posterior self-healing by ionic cross-linking (Adapted with permission from Das et al . [55]).

Figure 3.18Stress–strain measurements to characterize self-healing behavior in BIIR samples modified with imidazolium (BIIR-i) when the healing was made at room temperature at different length times (blue lines) and when the first 10 minutes of heal was made at 100 °C (red lines), compared with an uncut sample (black line) (Adapted with permission from Das et al . [55]).

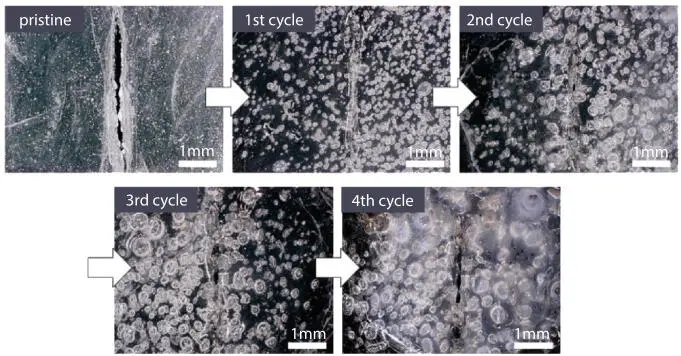

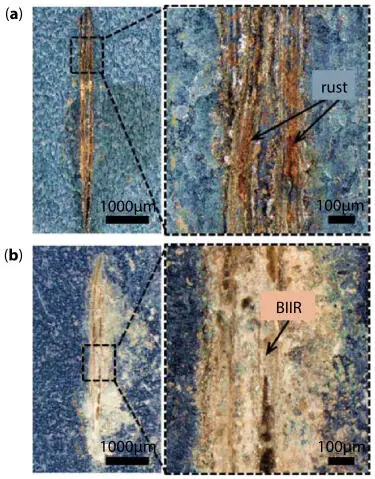

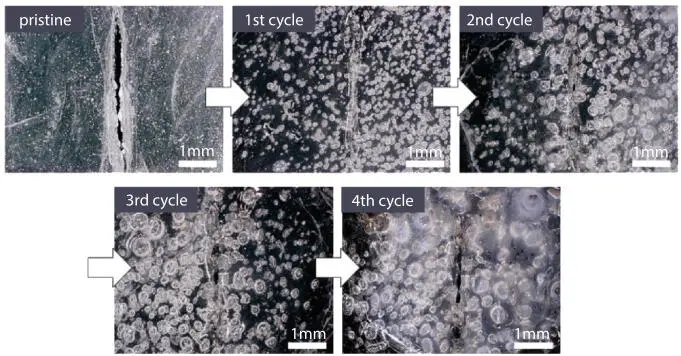

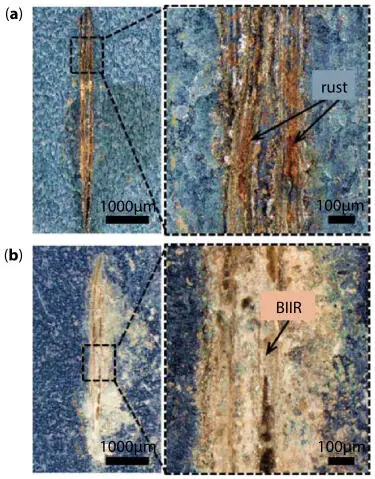

Lee and coworkers evaluated the self-healing property in pristine BIIR when is used as a coating to prevent corrosion, demonstrating that the healing process is highly stimulated by temperature by using a copper nanofiber as heater [56]. Kim et al. proposed a bilayer of BIIR over another one of BIIR with carbon nanotubes (in a concentration between 7 and 10 wt.%). The latter was used as heater to improve the self-healing efficiency [57]. The bi-layer was prepared through different methods: casting, painting and spraying. The angle between the applied current and the performed linear crack was varied (0, 45 and 90°) in order to study the influence of the current direction in the self-healing process. In the case of a current parallel to the crack orientation, the healing process took 2.5 h, while in the case that the current and the crack direction are parallel just 1 h is required. Then a repeating healing was performed, founding that up to a third cycle the material self-healed successfully when the sample is heated during 1 h in each cycle, as can be seen in Figure 3.19. Finally, they performed corrosion tests by applying the bi-layer in a steel substrate. To this aim, a deep scratch was made in 2 samples which were submerged in saline water and only one of the samples was heated during 1 h. After 72 h under the saline bath, the bi-layer was removed from the samples and the steel surface was observed, founding rust in the sample that was not heated (Figure 3.20).

Figure 3.19Bi-layer of BIIR and BIIR-CNT. Repeated healing test under water, the electrical current is perpendicular to the crack direction and is applied during 1 h in each cycle (Reprinted with permission from Kim et al . [57]).

Figure 3.20Bi-layer of BIIR and BIIR-CNT in a steel substrate to evaluate corrosion test in saline water during 72 h. (a) without heating, (b) with heating (Reprinted with permission from Kim et al . [57]).

The silicone is characterized for its insulating properties, chemical and thermal stability, outstanding weatherability and transparency [58–60]. Some of the most common applications are automobiles, electronics, medical implants, sportswear and shoes, among others.

In some cases, it is necessary that the insulating material needs to transmit the heat generated, for example, in electronic circuits. Several authors [61] are currently working on the development of insulating materials with thermally conductive loads with desirable self-healing properties.

Zhao et al. [58] used thermally conductive composites based on silicone for electronic packaging materials. The challenge is to fabricate functional composites with two main characteristics: self-healing ability and high thermal conductivity. Self-healing silicone was formulated with boron nitride (BN) in order to induce the DA reaction. After the tensile test, samples were submitted to pressure and temperature to join the broken surfaces. The final material exhibited a high self-healing efficiency (almost 90%) and an increase in thermal conductivity about 500% with just 50 wt.% of BN. From Figure 3.21, it is possible to compare the stress–strain curves before and after healing process of the silicone elastomer and composites, observing a high structural recovery with 50 wt.% of BN. Authors explain that, due to the hindrance of the BN nanosheets, the mobility of low molecular oligomer is reduced, so it is necessary to apply certain external force (for example pressure) to facilitates the chain diffusion in the damaged interface of the composite to produce an optimal self-healing process.

Читать дальше