Part 1

Getting Started with Supply Chain Management

IN THIS PART …

Simplify the concept of supply chain management by breaking it into pieces.

Analyze supply chain management from different perspectives to see why it’s important.

Align supply chain management with the goals of your business.

Optimize supply chain performance to drive better results for you, your suppliers, and your customers.

Chapter 1

The Growing Demand for Supply Chain Management

IN THIS CHAPTER

Understanding complex business challenges

Understanding complex business challenges

Focusing on supply chain tasks

Focusing on supply chain tasks

Understanding supply chain management principles

Understanding supply chain management principles

Getting started with the New Supply Chain Agenda

Getting started with the New Supply Chain Agenda

These days, it’s hard to find a copy of The Wall Street Journal that doesn’t have the phrase supply chain somewhere on the first page. You hear about supply chains everywhere: in company reports, on the news, and even in casual conversation. But it hasn’t always been that way. Only in the past 35 years has supply chain management gone from being a vague academic concept to a critical business capability. This chapter covers why supply chain management has become so important and explains the process for building best-in-class supply chain management into your company.

Defining Supply Chain Management

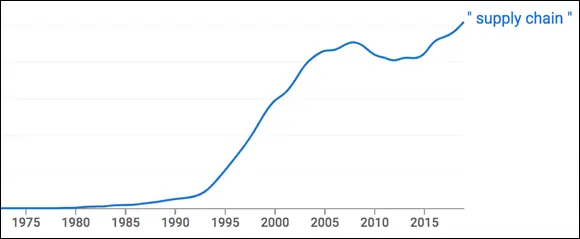

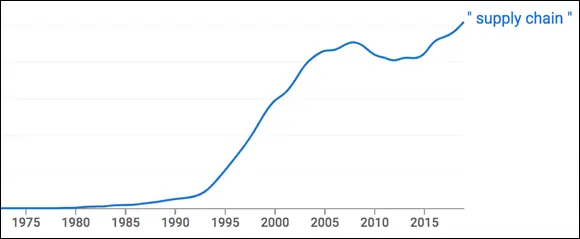

In spite of the current hype, supply chains aren’t really that new. Entrepreneurs have been buying things from suppliers and selling products to customers for almost as long as people have inhabited the earth. Supply chain management is new, however. In fact, the basic principles of supply chain management began to take shape in the 1980s, at about the same time that personal computers came onto the business scene. You can see the trend clearly by using Google’s N-Gram Viewer, shown in Figure 1-1, which illustrates how often the term supply chain has been used in book titles.

FIGURE 1-1:Frequency of supply chain in book titles.

Supply chain management is the planning and coordination of all the people, processes, and technology involved in creating value for a company. Managing a supply chain effectively involves aligning all the work inside your company with the things that are happening outside your company. In other words, it means looking at your business as a single link in a long, end-to-end chain that supplies something of value to a customer.

The word value shows up a lot when people talk about supply chain management. Basically, value means money . If a customer is willing to pay for something, it has value.

The word value shows up a lot when people talk about supply chain management. Basically, value means money . If a customer is willing to pay for something, it has value.

Negotiating prices, scheduling manufacturing, and managing logistics all affect the value equation for a company, and they’re critical to a supply chain, but because they’re so interdependent, it’s a bad idea to manage them separately, in silos. As companies grow larger, supply chains get longer, and the pace of business gets faster, making it more important to align the various functions in a supply chain. Ironically, many of the strategies and metrics that businesses relied on in the past, and that managers have been taught to use, can actually drive the wrong behaviors. A sales rep might hit her quota by landing a huge deal with a customer, for example, but the deal might be unprofitable for the company because of the costs it will drive to the logistics and manufacturing functions. Sales, logistics, manufacturing, procurement, and all your other functions need to be aligned to ensure that the business is pursuing profitable deals.

The difference between the amount of money your company brings in (revenue) and the amount of money it spends (costs) is your profit. In other words, your profit is the amount of value that you have captured from your supply chain.

The difference between the amount of money your company brings in (revenue) and the amount of money it spends (costs) is your profit. In other words, your profit is the amount of value that you have captured from your supply chain.

On the other hand, companies that do a good job of managing their supply chain are better able to take advantage of value-creation opportunities that their competitors might miss. By implementing lean manufacturing, for example, companies can reduce inventories. By being responsive to customer needs, they can build stronger relationships with their customers and grow their sales. By collaborating closely with their suppliers, they can get access to the materials they need, when they need them, and at a reasonable cost.

Part 4of this book is all about ways you can use supply chain management to create more value.

Part 4of this book is all about ways you can use supply chain management to create more value.

Keeping all the parts of the supply chain aligned is key to ensuring that revenue is greater than costs and running any business successfully. That’s why supply chain management has become so important so quickly.

Exploring Complex Business Challenges

Managing a business is like playing a full-contact sport: So many moving pieces are involved, and so many things can change in an instant, that making long-term plans is virtually impossible. How can you really plan for commodity price swings, natural disasters, and financial meltdowns? You can’t. You can’t ignore those possibilities, either. Instead, you need to think about them and design your business so that it can function well under a range of scenarios. In other words, you need to think about the many possibilities that the future holds, try to imagine each one as a series of events, and then think about how it would affect your business.

To use scenario planning to prepare for the unknown and the unknowable, you need to understand three really important things:

Which scenarios are most important to you.

What you’ll do — and how — in each scenario. (Each scenario calls for a different plan.)

How you can tell when a scenario is becoming reality. You need to have triggers that help you decide when to implement which plan. Then the job of supply chain management becomes a process of sensing and responding to those triggers.

You need to determine how your business will sense what’s happening and how events will respond. Figure 1-2 shows how your sensors help you recognize which scenario is unfolding so that you can implement the proper plan.

FIGURE 1-2:Scenario-planning model.

I can explain this concept with a few practical examples:

You run a manufacturing company that imports products from overseas, so you need to consider what you’d do if one of your inbound shipments is lost at sea, impounded by customs, captured by pirates, or caught in a port strike. One option might be shutting down your factory until the issue is resolved. You might also consider placing a new order with a different supplier. In an extreme case, you might declare force majeure and tell your customers that you won’t be able fulfill your commitments to them. Force majeure is a legal concept used in contracts to free one or both parties from liability if they’re unable to meet their obligations due to an extraordinary circumstance.

Читать дальше

Understanding complex business challenges

Understanding complex business challenges

The word value shows up a lot when people talk about supply chain management. Basically, value means money . If a customer is willing to pay for something, it has value.

The word value shows up a lot when people talk about supply chain management. Basically, value means money . If a customer is willing to pay for something, it has value.