2.4.2 Piezoresistive Sensor

In recent years, CPC based pressure sensors as a branch of smart material, which could respond to compressive deformation and transform mechanical forces into electrical signals, have been extensively developed [134]. To meet the demands of different applications, innovated material structures and fabrication strategies are developed to prepare flexible and wearable pressure sensors with excellent sensing performance. CPCs containing an elastic matrix and conductive nanofillers are the most popular candidates of the piezoresistive sensor [135]. Textiles with fiber networks are often used as flexible scaffolds of piezoresistive sensors by carbonization or coating conductive fillers onto the fiber surface [136, 137]. Li et al. [137] fabricated flexible and electrically conductive carbon cotton (CC)/PDMS composites by infiltrating PDMS glue into the CC scaffold. The CC/PDMS demonstrates a sensitivity of 6.04 kPa −1, a working pressure of 700 kPa and durability over 1000 cycles. CPCs with a porous structure (foam, aerogels) are another ideal active materials of piezoresistive sensors because of their highly reversibility and hence reusability after large-deformation cycles [138, 139]. Zhong and coworkers [140] successfully fabricated lightweight MXene (Ti 3C 2) aerogel with ultra-stable lamellar structure by freeze drying the mixture of bacterial cellulose fiber and MXene nanosheets. The carbon aerogel used for pressure sensor demonstrates ultrahigh compressibility and superelasticity, a wide linear range and low detection limits.

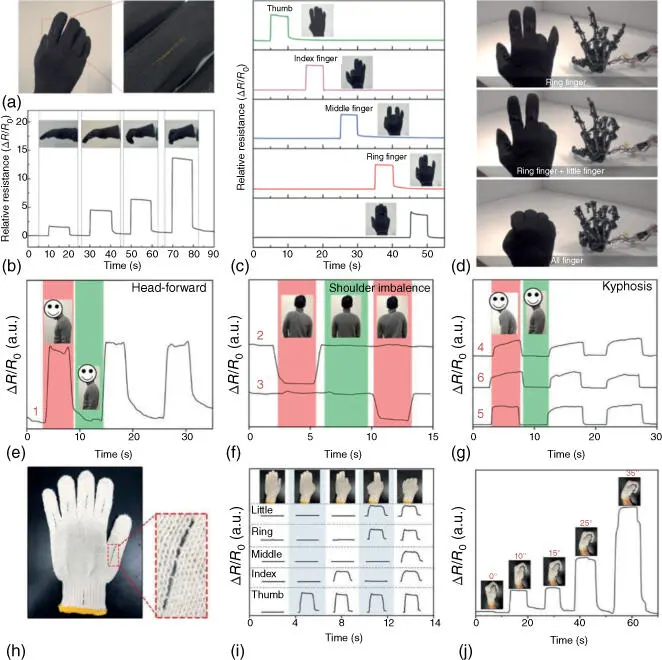

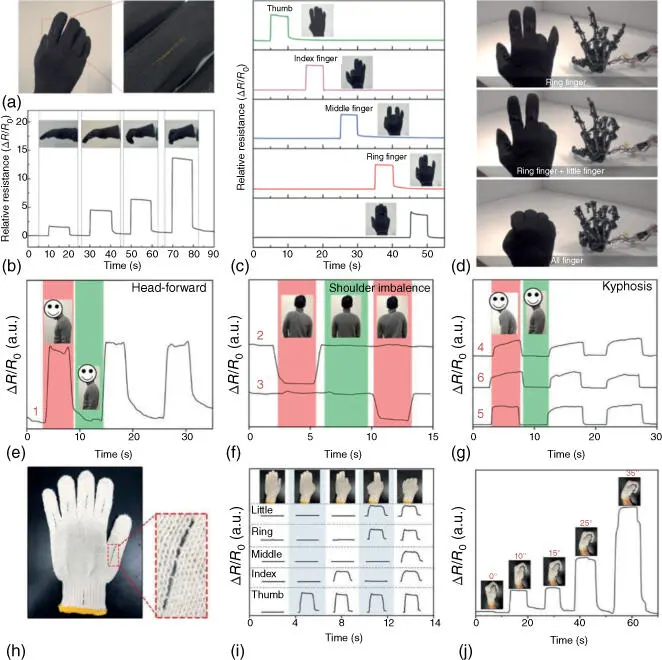

Figure 2.6 (a) Photograph showing the smart glove integrated with the fiber composites. (b, c) Strain sensing behavior of the smart glove for (b) fingers bending and (c) a full bending stimulation of each finger. (d) Photographs showing the hand robot operated by the smart glove. Source: (a)–(d) Reproduced with permission. [111] Copyright 2018, American Chemical Society. Relative resistance change of the sensor responding to various postures: (e) head-forward, (f) shoulder imbalance, and (g) kyphosis, respectively. (h) Photos showing a smart glove incorporated with fiber composite. Strain sensing behavior of the smart glove for (i) different gestures of the five fingers and (j) different bending angels of the wrist. Source: (e)–(j) Reproduced with permission. [114] Copyright 2019, The Royal Society of Chemistry.

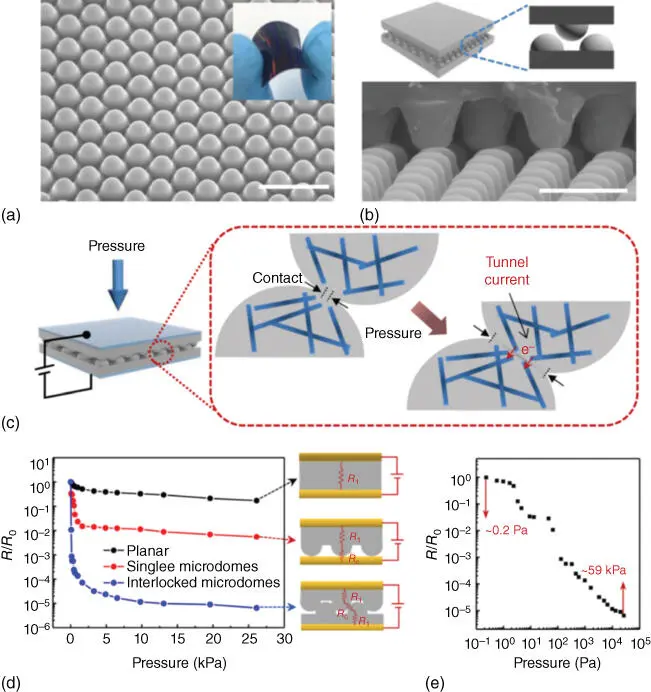

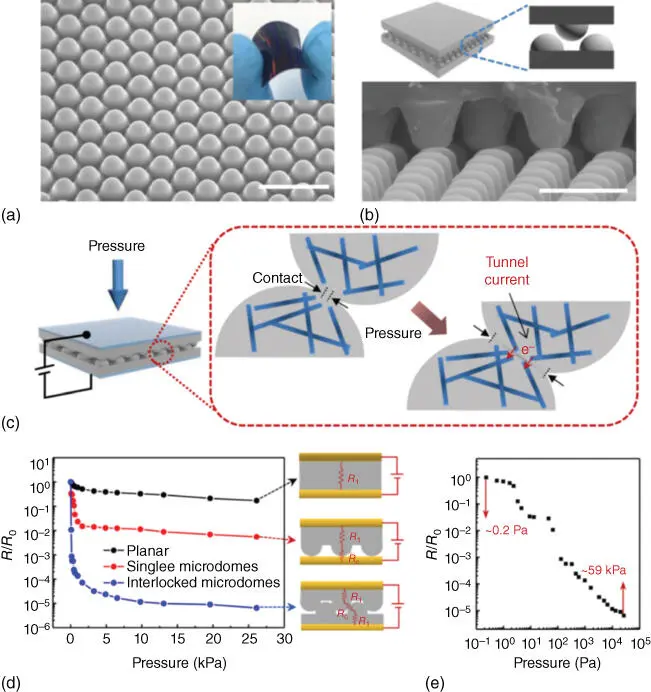

To enhance the response intensity and low detection limit, CPCs with delicate structures like fingerprint pattern [141, 142], microdome or micropillar array [143, 144], hair of human skin [145], plant leaves [146, 147], hollow spheres [148], etc. were studied. Park et al. [149] have reported flexible piezoresistive sensor by building interlocked microdome arrays on the elastomer composite film. The flexible film with regular microdome arrays can be observed by SEM as shown in Figure 2.7a. The inset picture demonstrates its excellent flexibility. The schematic diagram (top) and SEM image (bottom) of the fracture surface for the composite films are shown in Figure 2.7b, and an interlocked structure can be observed. The operating principle of the sensing device is also schematically illustrated in Figure 2.7c. Under the stress of external pressure, the microdomes would deform and the contact area between interlocked microdomes was increased, which in turn influenced the tunneling resistance of the sensor. Figure 2.7d shows the pressure sensing performance (relative electrical resistance ( R / R 0)) of composite film with different structures. The film with interlocked microdomes demonstrates a sharp decrease in R / R 0when the applied pressure increases from 0 to 10 kPa, while the sensing signals for films with single microdome arrays and planar structure are much weaker. Also, the sensing curve (log–log plot) of R / R 0vs. pressure demonstrates a high linearity ( Figure 2.7e), indicating an exponential dependence of resistance on the applied pressure.

Bae et al. [144] prepared highly linear and sensitive graphene/PDMS composite films with microdome structures. They found that pressure sensor made of hierarchical graphene/PDMS array with wrinkles on the surface of the microdome was more sensitive to external stimuli than sensor made of smooth-dome graphene/PDMS array. This novel type of pressure sensor exhibits a superb endurance of 10 000 cycles and a low detection limit of 1 Pa.

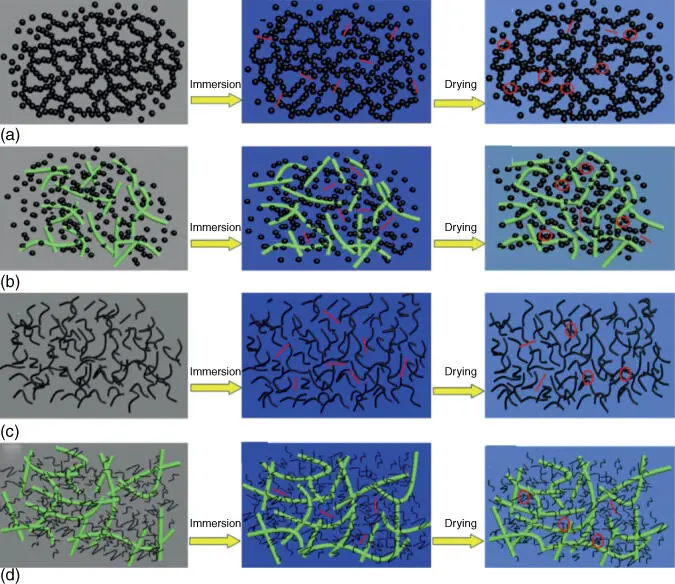

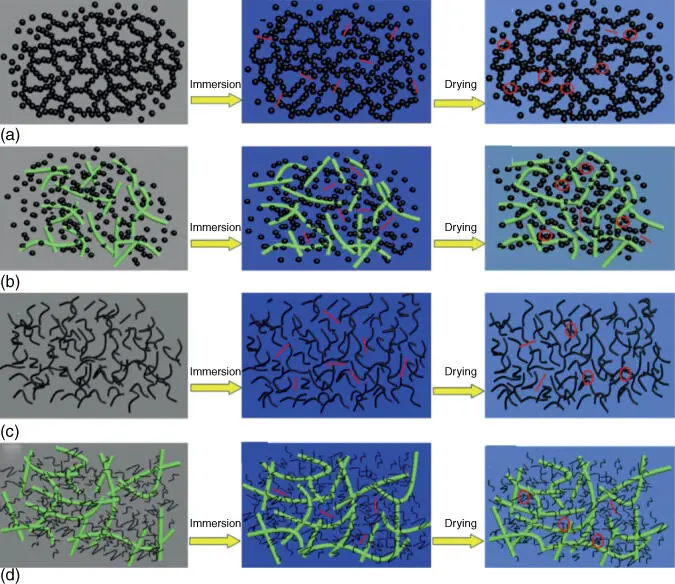

CPCs based gas sensors have also aroused tremendous attention for application in detecting or quantifying organic vapors or liquids chemicals [150, 151]. The electrical resistance of the CPC usually undergoes change when the sensor is exposed to organic vapor or liquid. The sensing mechanism of the gas sensor can be discussed on the basis of percolation theory. Upon exposure to vapor or liquid, the interaction between polymer matrix and gas would cause polymer expansion, resulting in the redistribution of the conductive nanofillers hence change of resistivity. Once the sensor is removed from the vapor stimuli, the resistance of the CPC recovers to its original value due to the desorption of vapor [152, 153]. Li et al. [154] proved a schematic illustration of the conductive networks formed by different fillers in sensing process shown in Figure 2.8a–d. It can be observed that the dispersion state of conductive nanoparticles (CB, CNTs) in poly(lactic acid) (PLA) matrix ( Figure 2.8a,c) are quite different from that of ramie fiber (RF)/PLA ( Figure 2.8b,d), resulting in different sensing mechanism. They found the addition of RF greatly tailored the vapor sensing behaviors of CB/PLA and CNTs/PLA composite.

Figure 2.7 (a) SEM image showing the surface morphology of the composite elastomers (scale bar: 10 μm); Inset photograph shows the flexibility of the film composite. (b) Schematic diagram (top) and SEM image (bottom) of the fracture surface for the composite films (scale bar: 5 μm). (c) Schematic illustration demonstrating the operation principle of the film composite. (d) The pressure sensing performance of composite film with different structures. (e) Relative resistance ( R / R 0) as a function of applied pressure (log–log plot) for the sensor with interlocked microdome arrays (8 wt% CNTs). Source: (a)–(e) Reproduced with permission. [149] Copyright 2014, American Chemical Society.

Many efforts have been paid to modify the sensitivity, selectivity, and recoverability of vapor sensors. Gao et al. [116] reported a superhydrophobic PU@SEBS/carbon nanofiber (CNF) composite vapor sensor to improve water proof and corrosion resistance. The superhydrophobic membrane could be easily wetted by different solvents, corresponding to a rapid response time. The sensor is also sensitive to both polar and non-polar vapors. It is obvious that the PU@SEBS/CNF composites show different sensing behavior to tetrahydrofuran (THF), toluene, and heptane as shown in Figure 2.9a–c.

Figure 2.8 Schematic illustration of conductive networks formed by carbonaceous filler in PLA during immersion-drying runs. (a–d) Illustrating the evolution of conductive networks in CB/PLA, CB/RF/PLA, CNTs/PLA, and CNTs/RF/PLA, respectively (the red lines and circles suggest the changes of conductive paths). Source: (a)–(d) Reproduced with permission. [154] Copyright 2015, Elsevier B.V.

Читать дальше