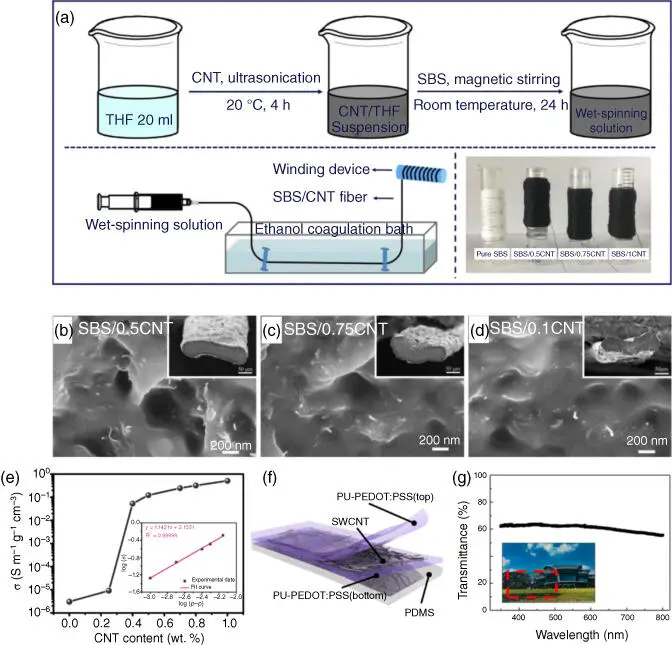

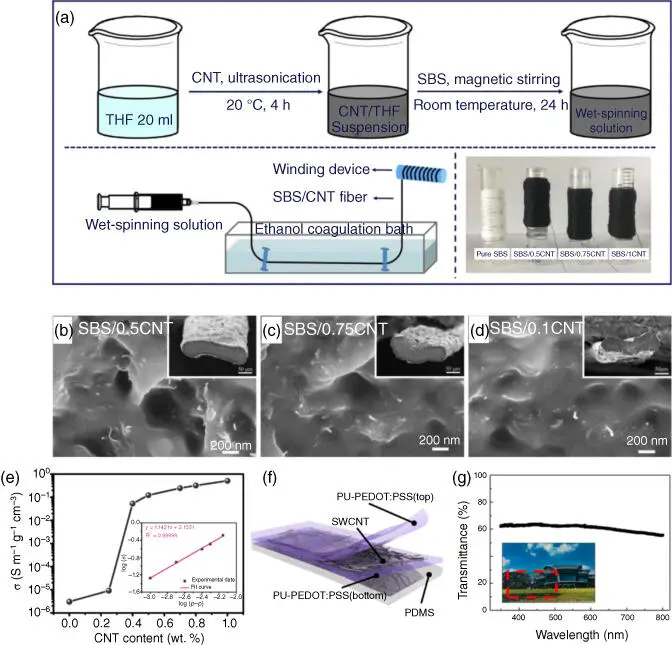

Figure 2.3 (a) Schematic diagram illustrating the preparation procedure for SBS/CNT fibers (SCFs) and photograph of SCFs with the various content of CNT. (b–d) The cross-sectional morphologies of SBS/CNT fibers containing different content of CNT. (e) The specific conductivities of SFCs as a function of different loading content of CNT. Source: (a)–(e) Reproduced with permission. [80] Copyright 2018, Elsevier Ltd. (f) Schematic illustration of the PU-PEDOT:PSS/SWCNT/PU-PEDOT:PSS with sandwiched structure on a polydimethylsiloxane (PDMS) substrate. (g) Transmittance of the integrated composite in the visible wavelength range from 350 to 700 nm. Source: (f)–(g) Reproduced with permission. [81] Copyright 2015, American Chemical Society.

Thin film-like CPCs can be fabricated by facile casting or template molding [82, 83] or polymer encapsulation [81, 84–86]. A stretchable, transparent, patchable nanohybrid conductive polymer film was reported by Roh et al. [81]. The CNTs were encapsulated in the interlayer of polyurethane (PU)-poly(3,4-ethylenedioxythiophene) polystyrenesulfonate (PEDOT:PSS) forming a sandwich-like structure, which is schematically illustrated in Figure 2.3f, where the CNTs functioned like a bridge that connects the conductive PEDOT to the PEDOT phases. The obtained sandwich-like composite with 5 mg ml −1SWCNT dispersion is optical transparent and shows the optical transmittance of 62% in the visible range ( Figure 2.3g).

In terms of three-dimensional composite, nanofillers are often distributed in a foam composite that is usually obtained by freezing drying method [87, 88]. For example, Huang et al. [87] fabricated a novel aligned porous CNT/thermoplastic polyurethane (TPU) foam composite by using a directional-freezing method. During the freezing–drying process, the solvent of the mixture would form directional crystal due to the low temperature and then the ice crystal of the solvent would be sublimated, leaving aligned interconnected pores.

2.3.2 Selective Distribution of Nanofillers on the Interface

To reduce the content of conductive fillers in polymer matrix and at the same time maintain a relatively high conductivity of the CPCs, researchers try to locate conductive fillers on the interfaces of the polymer granule (i.e. segregated structure) or on the skeleton (surface coating) of the porous materials. Also, when used as sensors, the specially distributed conductive paths are easier to destruct upon external stress compared with conventional CPCs with relatively strong and dense conductive paths.

2.3.2.1 Segregated Structure

The study about construction of segregated structure was first reported in 1971 [89], and to date much work have been done on this topic [15, 30, 90]. In fact, segregated structure is a unique dispersion state of the conductive fillers in the polymer matrix, at which conductive fillers are dispersed at the interfaces between polymer particles. Mechanical blending and hot compression molding technique is usually applied to fabricate CPCs with a segregated structure [91, 92]. Generally, conductive fillers such as CNTs and graphene were adsorbed to the surface of polymer microspheres by chemical or physical methods, and then the temperature and pressure of hot pressing were controlled, guaranteeing that the conductive fillers were only distributed at the interface between polymer microspheres instead of evenly dispersed in the whole polymer matrix [15, 93, 94].

For example, Wu et al. [95] added amino-functionalized PS microspheres suspension into the GO solution. Graphene was tightly coated on the surface of PS microspheres after a series process of flocculation, filtration, washing, and hydroiodic acid reduction. The composite with a low percolation value of 0.15 vol% was obtained after hot press of the graphene coated PS microsphere. Also, the conductivity of the composite could reach as high as 1024.8 S m −1when the volume content of graphene is 4.8%, which is much higher than that of PS/graphene and PS/CNT composite made by solvent blending.

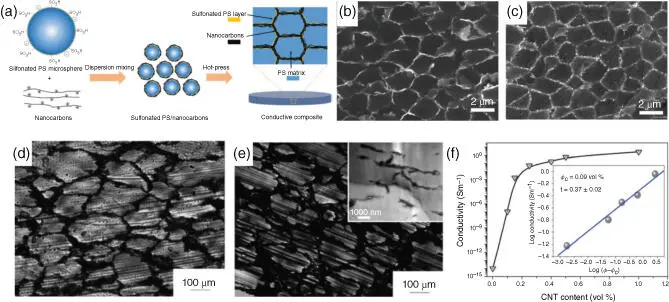

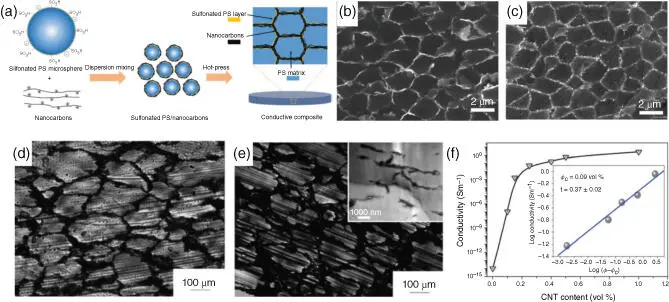

An ultralow percolation threshold of 0.047 vol% was achieved by Cui and Zhou [92]. In their work, the conductive PS/graphene and PS/MWCNTs composites with segregated structures were obtained by hot press surface sulfonated PS microspheres and protonated triethylenetetramine functionalized perylene bisimide (HTAPBI)-stabilized nanocarbon. The formation of conductive PS composites with a segregated network is schematically demonstrated in Figure 2.4a. The SEM micrographs of the fracture surface of PS composites containing 0.94 vol% graphene sheets and 0.94 vol% MWCNTs are displayed in Figure 2.4b,c, respectively. Due to the strong electrostatic attraction between the negatively charged PS and positively charged nanocarbon, the interconnected conductive pathways could be preserved regardless of a high hot press temperature, leading to an ultralow percolation threshold.

Figure 2.4 (a) The fabrication process of PS–nanocarbon composite with interconnected networks. Cross-sectional SEM images of PS composites with (b) 0.94 vol% graphene sheets and (c) 0.94 vol% MWCNTs. Source: (a)–(c) Reproduced with permission. [92] Copyright 2017, The Royal Society of Chemistry. Morphologies of double-segregated (d) CNT/PMMA/UHMWPE (0.2/7.8/92.0 by volume) and (e) CNT/PMMA/UHMWPE (0.5/16.2/83.3 by volume) composites. The inset transmission electron micrograph (TEM) image in (e) shows the state of the segregated CNT conductive network in the CNT/PMMA layers. (f) The variation of electrical conductivity for the double segregated CNT/PMMA/UHMWPE composites with different CNT content. Source: (d)–(f) Reproduced with permission. [96] Copyright 2013, The Royal Society of Chemistry.

Pang et al. reported CPCs with double-segregated structure [96, 97]. CNTs wrapped around the small-sized PMMA particles to form the first layer of segregated structure, and CNTs/PMMA were distributed at the interface of the large-sized ultrahigh molecular weight polyethylene (UHMWPE) particles to construct a second layer of segregated conductive network throughout the whole system. The optical micrographs of CNT/PMMA/UHMWPE composite with 0.2 and 0.5 vol% CNTs are shown in Figure 2.4d,e, respectively, showing perfect double-segregated structure. Figure 2.4f shows the electrical conductivity of CNT/PMMA/UHMWPE composites as a function of CNT content. The percolation value of the CPC was calculated to be only 0.09 vol% [96].

Another kind of segregated structure can be constructed by infiltration of flexible elastomers into conductive foams. Carbon based foams (e.g. graphene and CNTs) and carbonized polymer foams are usually selected as the conductive skeleton and polydimethylsiloxane (PDMS) ink was impregnated in the foam to prepare the CPCs [98–100].

To prepare CPCs with a low percolation, a high conductivity at a low filler content, and meanwhile no evident fillers aggregation in polymer matrix, decoration of conductive nanofillers on the skeleton (out surface) of the polymer material tends to be an effective solution, which includes dip coating [101, 102], spray coating [103, 104], and ultrasonication [105, 106]. Note that the polymer materials usually possess a porous structure (e.g. fabric and foam), which facilitates the nanofillers penetration into the interior of the material during the surface coating.

Читать дальше