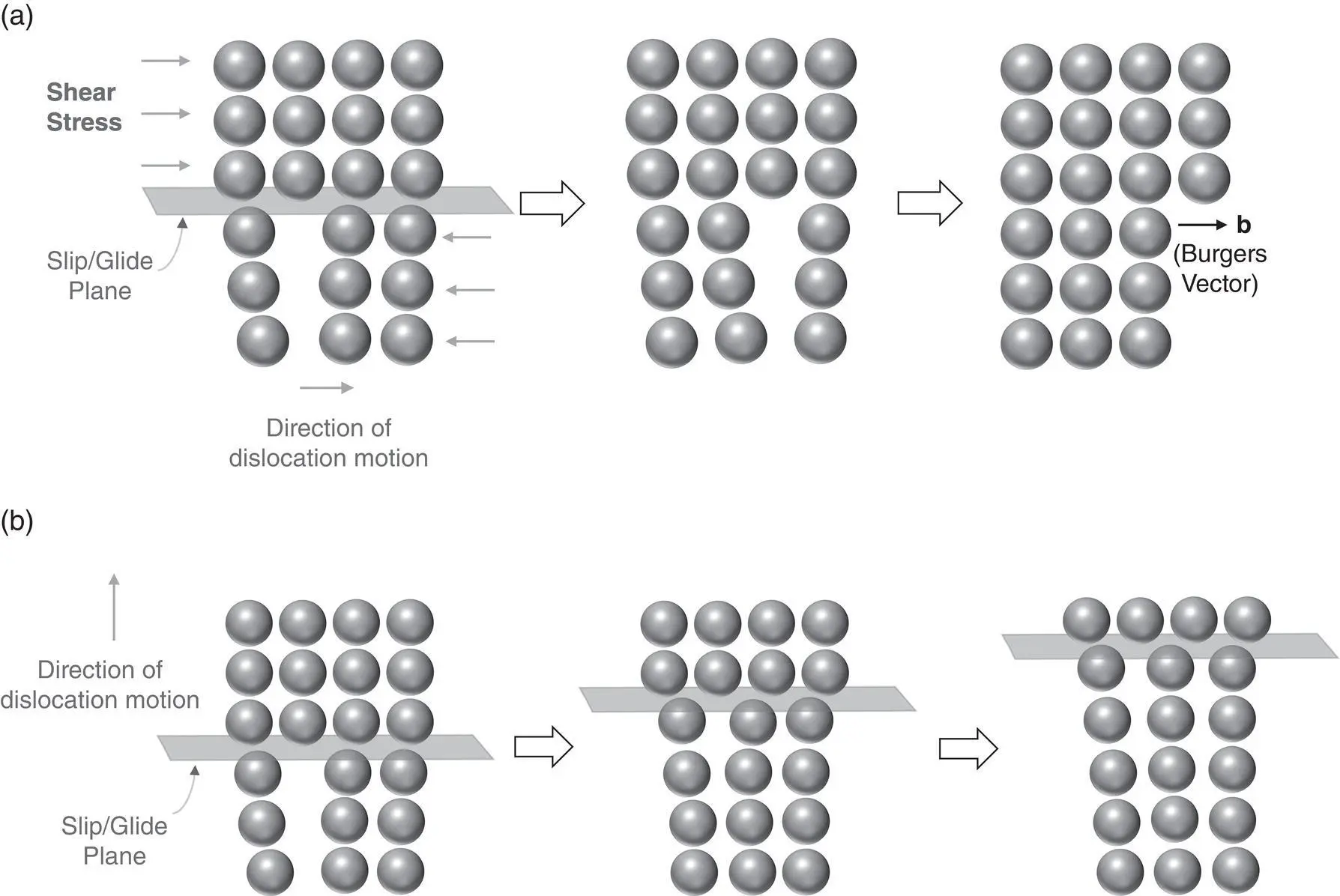

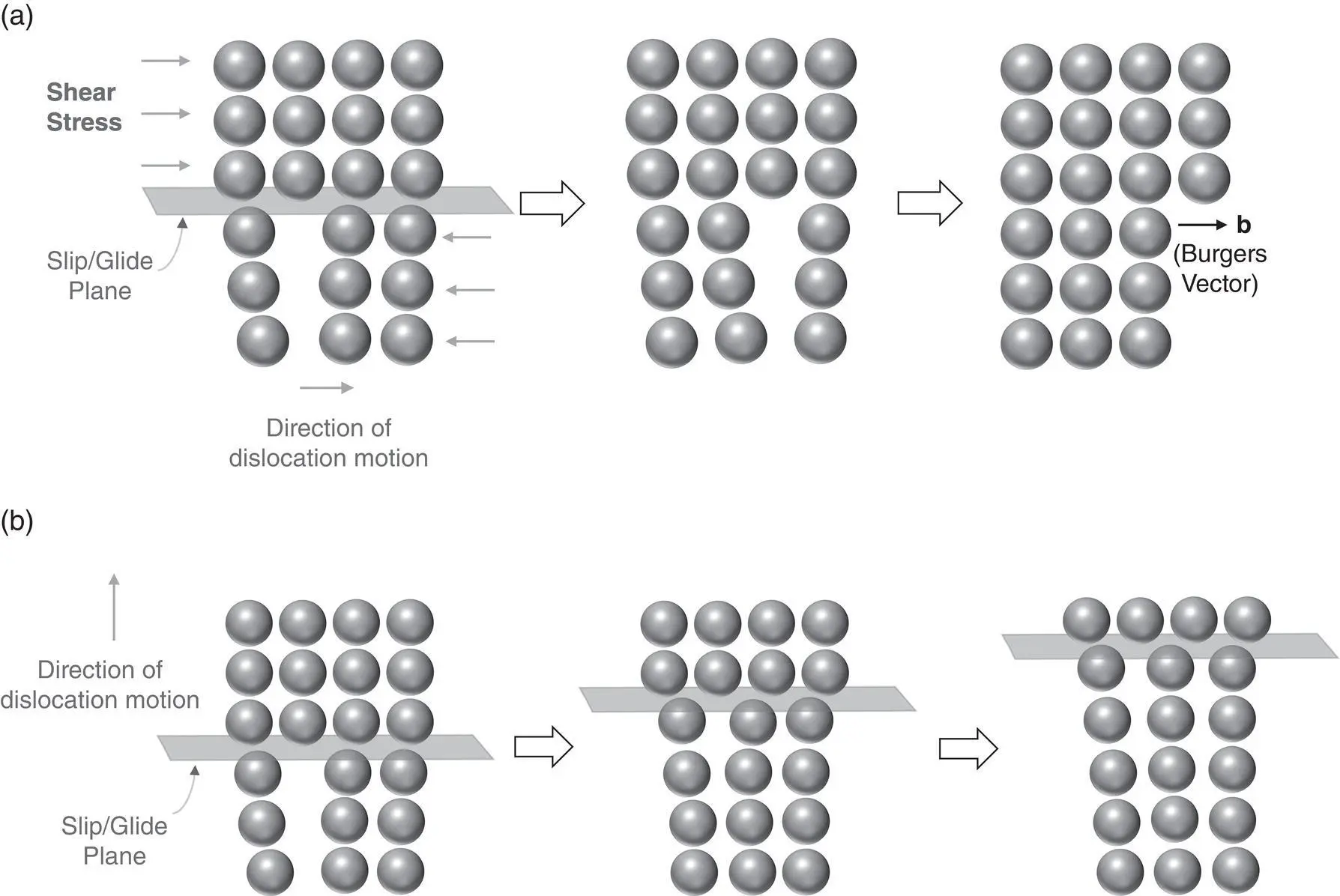

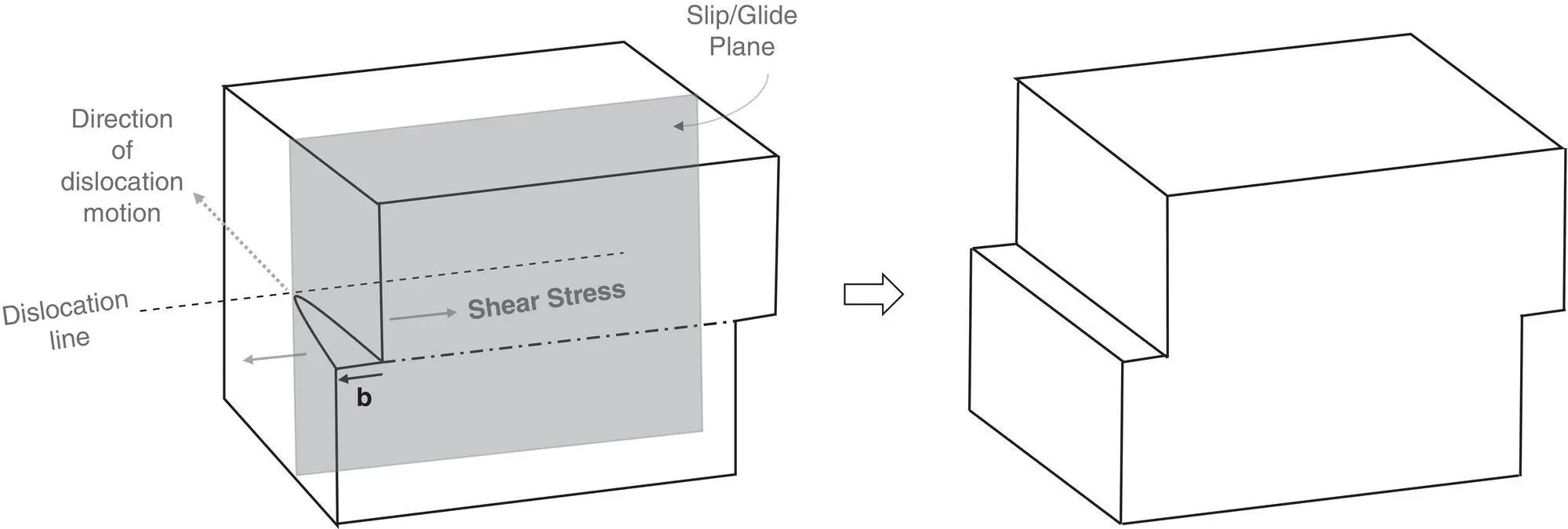

Edge dislocations can be visualized as an extra partial plane of atoms. As shown in Figure 2.6, the partial plane continues into the direction of the page such that the edge dislocation line runs into the plane of the page. Creation and motion of edge dislocations across the crystal results in relative shear or slippage of planes of atoms past each other. There are generally two types of dislocation motion: slip/glide and climb.

In dislocation glide, as shown in Figure 2.6a, the slip plane is the plane in which the dislocation moves and is generally the most closely packed plane in the crystal. A family of close‐packed planes can all act as potential slip planes. As such, the crystal system of the material determines how many glide planes are possible. However, the orientation of the differential stress determines which glide planes are active or not. The edge dislocation moves in the slip plane in the direction of the shear and generally corresponds to one of the shortest lattice translation vectors in the material. The Burgers vector ( b) represents the magnitude and direction of the lattice distortion resulting from a dislocation in a crystal lattice. The Burgers vector and the edge dislocation are perpendicular to each other and define the slip plane. Real dislocations will not always be in a straight line and can move along more than one slip plane.

Figure 2.6 Schematic of the basic motion or propagation of an edge dislocation. (a) Dislocation glide or slide as a result of shear stress. (b) Dislocation climb involving material transfer from the dislocation core.

In edge dislocation climb, as shown in Figure 2.6b, the dislocation moves up or down out of its slip plane to a parallel slip plane. This involves the creation or annihilation of a row of vacancies and is energetically difficult.

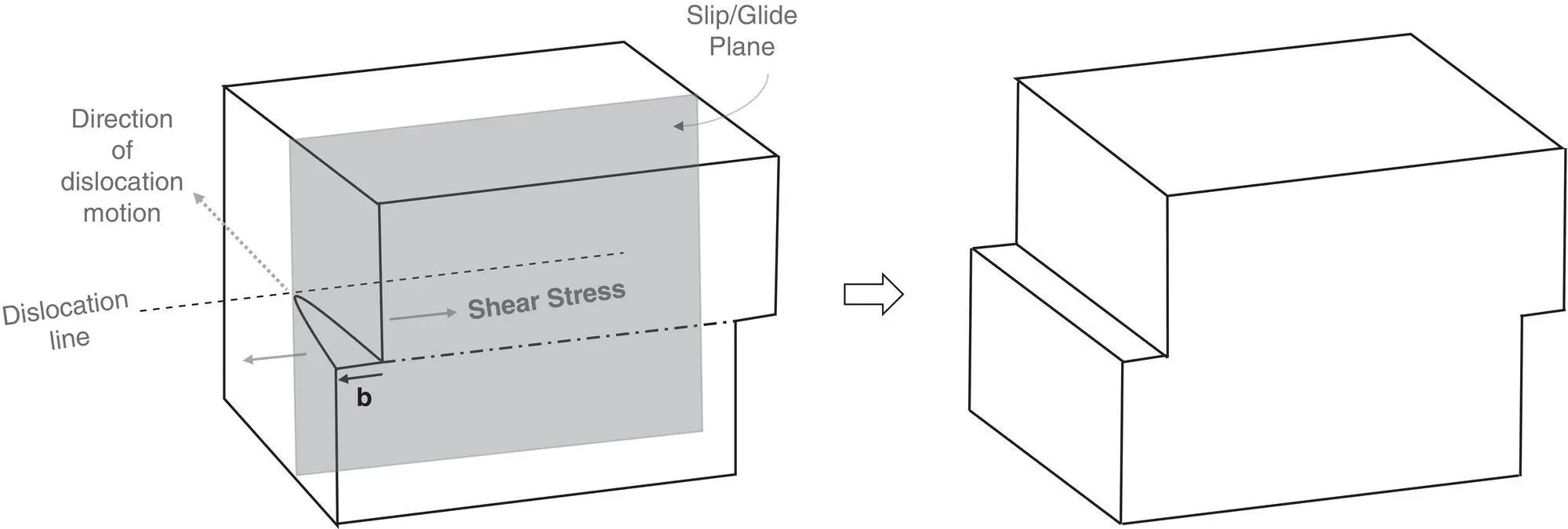

Figure 2.7 Schematic of the basic motion or propagation of a screw dislocation during plastic deformation.

Screw dislocations are harder to visualize, but result when a part of the crystal shifts relative to its other parts such that the dislocation motion is perpendicular to the applied stress ( Figure 2.7). The screw dislocation lies in its slip plane and the dislocation line is parallel to the Burgers vector. Screw dislocations may move from one glide plane to another or in more than one slip plane at a time in a process called cross slip, which is common at high temperatures and/or high stresses. In practice, real dislocations can occur as an intermediate or a combination of edge and screw dislocations. When the orientation of the dislocation line changes, an edge dislocation can continue as a screw dislocation and vice versa.

Dislocations generally require proper lattice ordering to move through a material at low energy. Barriers to the motion of dislocations can be created by the presence of other defects in the crystal, such as point defects, grain boundaries, other dislocations, and the precipitation of a secondary phase. In particular, precipitates can act as locations through which the dislocation might become pinned or must bend in order to continue moving. Bending around precipitates can often lead to the formation of dislocation loops formed around precipitates.

There are a variety of planar defects that can occur within crystals. Many of these are due to dislocation and the slip of atomic planes. A common imperfection is a result of stacking faults – a deviation of the stacking sequence of layers in a crystal, often due to a missing or added layer. Stacking faults occur in a number of crystal structures, but the common example is that in close‐packed structures. For example, the ABCABCABC sequence of an FCC crystal could be disrupted by a missing C‐layer giving an ABCABABCABC structure.

Another type of planar defect is the twin boundary. This defect introduces a plane of mirror symmetry. For example, in the FCC structure, stacking sequence of a twin boundary would be ABCAB‐ C‐BACBA.

A third type of planar defect is called the antiphase boundary. This defect occurs in ordered alloys where the crystallographic direction remains the same, but each side of the boundary has an opposite phase. For example, for the HCP crystal ABABABAB, an antiphase boundary takes the form of ABABBABA.

2.3.3.4 Intragranular Precipitates

Precipitates in a material are generally impurity phases that segregate during the solidification process. Precipitation can produce many different sizes of particles and can have vastly different impacts on material properties. Intergranular precipitates segregate into grain boundaries and take up volume between grains whereas intragranular precipitates are contained within grains and disrupt the crystal structure.

Trinity of Precipitate Classification

GEOMETRICALLY CLOSE‐PACKED

TOPOLOGICALLY CLOSE‐PACKED

CARBIDE

The process of precipitation hardening relies on changes in a material's solid solubility with temperature to produce fine particles of an impurity phase within grain interiors, which impede the movement of dislocations. During precipitation hardening, alloys must be kept at elevated temperature for a significant amount of time, called aging, for precipitation to take place. However, not all precipitates are created equal, and engineers must be careful to design the system and processes to produce the desired precipitates. There are three general classifications for precipitates: (i) Geometrically close‐packed (GCP) precipitates are phases that are close‐packed in all directions and generally provide positive influences on mechanical properties. (ii) Topologically close‐packed (TCP) precipitates are not close‐packed throughout the whole structure. They often have close‐packed layers separated by relatively large interatomic distances due to sandwiching larger atoms (Bowman 2000). With fewer available slip planes, these precipitates tend to have brittle behavior. Moreover, nonideal TCP phases can grow at the expense of desired GCP phases and result in a depletion zone of the desired participate phase (Belan 2016). (iii) Carbide precipitates can have quite different phase structures than their surroundings and can have extremely important impacts – both desired and undesired – on properties.

Solid materials are rarely made of pure single crystals. Different grains in polycrystalline material can be recognized by a mismatch in atomic alignment between regions in the solid. The grain boundaries are, in themselves, a source of great imperfection within a solid.

Small mismatches (less than 10–15° depending on the material) are called low‐angle grain boundaries or more commonly “subgrain boundaries.” Subgrain boundaries include “tilt” and “twist” boundaries and contain dislocations of various types. The energy of subgrain boundaries depends upon the degree of misorientation and types of dislocations.

High‐angle grain boundaries – or simply grain boundaries – separate regions with high mismatch in lattice arrangement. Grain boundaries are disordered regions associated with high energy. The disorder of grain boundaries is a result of not only lattice mismatch of adjacent grains, but also the segregation of various impurities and voids into the edge of the grains. Grain boundaries tend to have lower density and higher reactivity than the grains themselves. They can also act as conduits or pathways for various processes, such as corrosion, into the bulk.

Читать дальше