1 ...8 9 10 12 13 14 ...44

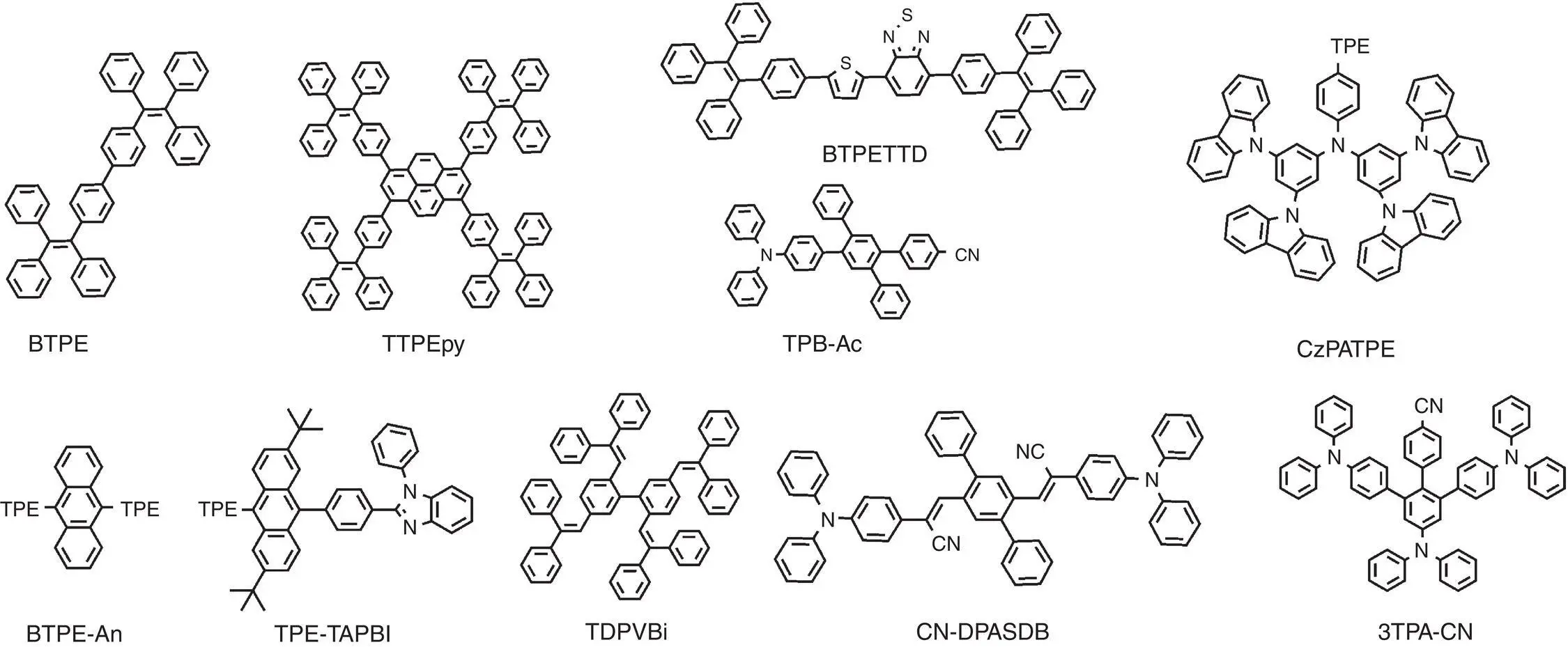

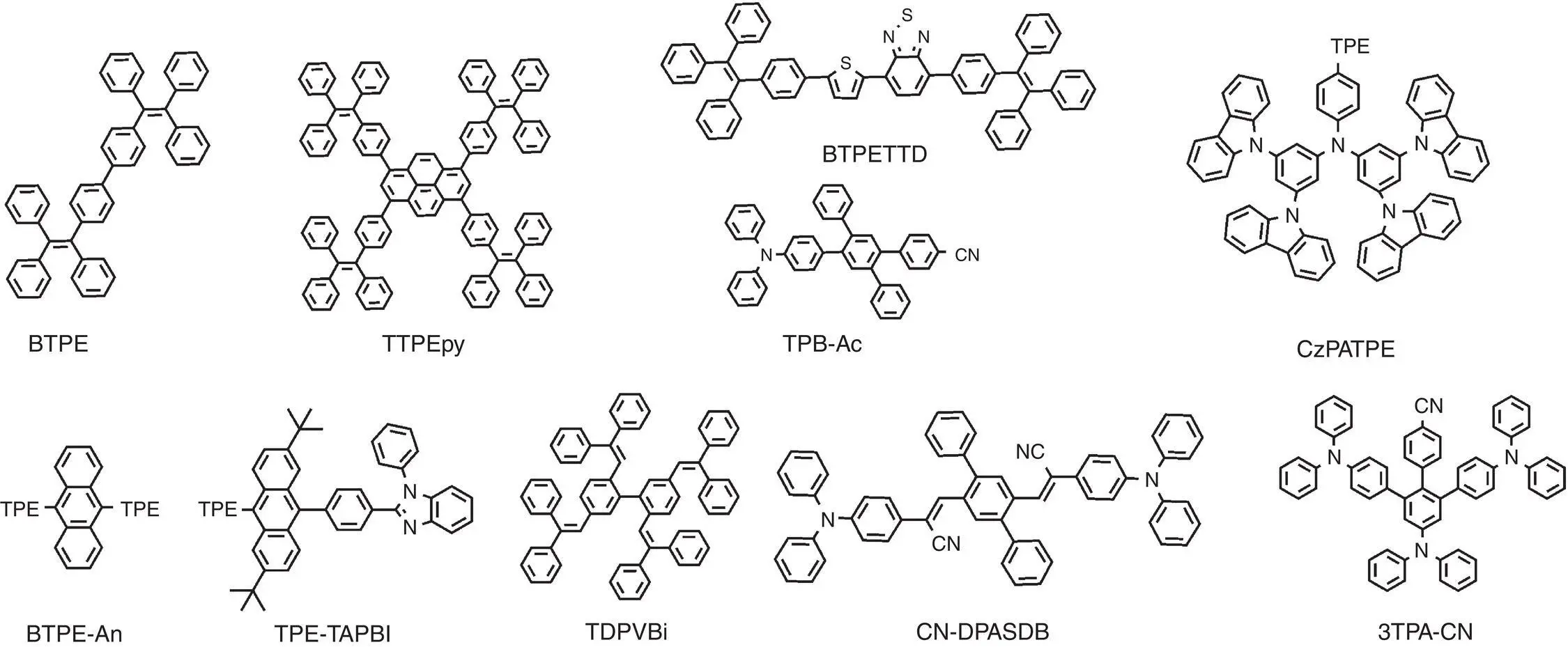

Figure 1.5 Molecular structures of conventional AIE‐active emitters to construct WOLEDs.

Although the doping approach can effectively overcome the ACQ problems, it usually requires precise control over the dopants concentration, and the resulting emission also suffers from the drawbacks of insufficient energy transfer. From this point, nondoped methodology can solve such problem, but it usually posed a challenge for the fabrication, because the EMLs with normal emitters for WOLEDs should be ultrathin, about 1 Å, in order to avoid the ACQ disadvantages [80]. In this prospective, the AIE luminogens can overcome these drawbacks of ultrathin fabrication, because they exhibited high PLQYs in aggregated state, therefore showing high potentials especially in nondoped WOLEDs. Tang et al. took advantage of bluish‐green AIE emitter of TTPEPy( Figure 1.5) and red AIE emitter of BTPETTDto prepare nondoped fluorescent WOLEDs, which exhibited the maximum luminance, CE, and PE, of 18 000 cd/m 2, 7.4 cd/A, and 4 lm/W, respectively, with a reduced efficiency roll‐off, a high color rendering index of 90, and high color stability over a wide range of driving voltages [81]. To further simplify the process and reduce the cost of OLED, nondoped bilayer WOLED was fabricated by two emitters BTPETTDand DPPiwith complementary colors of red and blue, respectively, while BTPETTD( Figure 1.5) and DPPialso served as the HTL and ETL, respectively. Through such a configuration, most of the excitons recombined in the DPPilayer gave off blue emission, while excitons captured by BTPETTDemitted red EL. And the bilayer WOLED based on the combination of these two emissions provided an efficient and stable white‐color emission, with CIE coordinates of (0.31, 0.31), CE of 4.2 cd/A at 1000 cd/m 2[82]. Similarly, Ma et al. used prepared nondoped WOLEDs by adopting two aggregation‐induced enhanced emission (AIEE) materials, TDPVBiand CN‐DPASDB( Figure 1.5) with blue and orange emission, respectively. And the related WOLED exhibited a maximum CE, PE, and luminance of 7.9 cd/A, 6.2 lm/W, and 25 350 cd/m 2, respectively [83].

In other research, blue AIE emitters were also mixed with phosphorescent emitters to prepare WOLEDs. Chen reported an AIEgen CzPATPE( Figure 1.5) with sky‐blue emission around 495 nm and high triplet gap energy E Tbetween 2.05 and 2.16 eV, making it possible to serve as the host material for the orange dopant of Ir(2‐phq) 3( E T∼ 2.13 eV). Through solution process, AIE hybrid white OLED were prepared with structure of ITO/PEDOT : PSS (65 nm)/ CzPATPE: Ir(2‐phq) 3(99.9 : 0.1, ∼40 nm)/TmPyPB (50 nm)/CsF (2 nm)/Al (100 nm), exhibiting white emission with CIE x,yof (0.36, 0.43) and the modest maximum EL and PE of 3.4 cd/A and 1.8 lm/W, respectively [84]. Tang et al. took advantage of blue AIEgen BTPEAn( Figure 1.5) and an orange phosphorescent emitter Ir(dmppy) 2 (dpp)to prepare nondoped WOLEDs, with high CRI and PE of 85 and 35.0 lm/W, respectively. Besides, based on the same blue AIEgen and other two phosphorescent emitters Ir(dmppy) 2 (dpp)and Ir(piq) 3of red and orange emission, respectively, they also prepared three‐color nondoped WOLED exhibits with CRI > 90 at ≥ 3000 cd/m 2[85]. In their further work, they utilized another blue AIEgen TPE‐TAPBI( Figure 1.5) as the nondoped blue‐emitting component to fabricate two‐color hybrid WOLEDs, with warm white light with CIE x,yof (0.45, 0.46) and PE, CE, and EQE of 70.5 lm/W, 76.0 cd/A, and 28%, respectively [86]. Recently, Tang and Ma reported several novel, blue AIEgen without typical AIE moieties such as TPE or silole to prepare WOLEDs. They prepared 3TPA‐CN( Figure 1.5) as both blue emitter and phosphor host for the red phosphore Ir(tptpy) 2 acacto fabricate nondoped hybrid WOLED, with maximum PE and EQE reaching 86.7 lm/W and 22.3%, respectively [87]. In another research, based on the same deep‐blue AIE material TPB‐AC( Figure 1.5) as both excellent blue emitter and host for phosphor emitters, two‐color and four‐color WOLEDs were prepared with high CRI (>90), EQE max> 25%, and PE max= 99.9 lm/W [88].

WOLEDs can also be obtained through the method of blue OLED with color down conversion layer (CCL), with the advantage of simple fabrication process and high color stability [89, 90]. Kowk et al. utilized orange‐red emissive emitter BTPETTD( Figure 1.5) as a CCL on top‐emitting blue OLEDs by thermal evaporation, with 74.5% of the blue emission converted to red emission at the efficiency of 40%. And resulting top‐emitting WOLEDs were realized by mixing the left blue and red emission, with CIE coordinate, CE, and PE of (0.34, 0.35), 17.7 cd/A, and 8.7 lm/W, respectively [91].

1.3 High Exciton Utilizing Efficient Aggregation‐induced Emissive Materials

Although AIE‐active conventional fluorescence have took up the majority of all AIE emitters, the maximum EQE values of their OLEDs are too low, with only 5% in theory, due to their capabilities of using only singlet excitons, with the loss of 75% triplet excitons. To further improve the efficiency of OLED devices, the AIE emitters were designed with other photophysical mechanisms, which can take advantage of triplet excitons for emission in both highly efficient and cost‐effective OLEDs. At present, the AIE properties have been combined with various photophysical strategies of high EUE such as phosphorescence [20], TADF [92], and HLCT [28–31] to prepare highly efficient emitters for OLED devices. Despite different photophysical mechanisms, all of them have the potentials to realize 100% EQE in theory. In the following paragraph, we will introduce each of these emitters combined with AIE and high EUE mechanisms in details.

1.3.1 Aggregation‐induced Phosphorescent Emissive Emitters

The phosphorescent OLEDs, as the second generation technique, can fully utilize both singlet and triplet excitons for 100% phosphorescent emission with the process of intersystem crossing from the lowest singlet excitons S 1to lowest triplet excitons T 1and further to the ground state S 0, due to spin–orbital coupling effect usually caused by heavy metals. In 1998, Ma et al. [93] and Forrest et al. [94] first reported that heavy‐metal complex of osmium(II) or platinum(II) complexes can generate phosphorescence within OLED devices. In last few decades, the phosphorescent OLED developed quite rapidly with numerous phosphorescent emitters, including Ir(III) [95, 96], Au(III) [97], Pt(II) [98], Cu(I) [99, 100], and Os(II) [101] complexes merchandized, and even some pure organic compounds with room‐temperature phosphorescence [102, 103] and AIPE materials [104, 105] were reported.

This AIPE phenomena were discovered first by Lu et al. in the metal complexes of oxo‐bridged Re(I) AIPE 1–3( Figure 1.6), with dim emission in pure acetonitrile solution, but a dramatic increase by adding water to this solvent [106]. Similar to AIE property, the AIPE phenomenon was also a result of the intramolecular motion restricted in mixed solvents. Till now, numerous AIPE compounds have been designed, but mainly applied in the areas of gas [107] or explosive detection [108], with limited applications in AIPE‐based OLEDs [109]. In 2011, Zhang, Zuo, and Zheng et al. designed the AIPE iridium complexes Ir(tfmppy)2(tpip)( Figure 1.6), and by doping it into the host of mCP, they prepared highly efficient OLED devices, exhibiting maximum luminance of 64 351 cd/m 2and a low efficiency roll‐off [110]. Likewise, He et al. took TPBI( Figure 1.6) and mCPas the bihosts for the AIPE emitter Ir(tfmppy) 2 (tpip), with the ratio of TPBI: mCP: Ir(tfmppy) 2 (tpip)at 1 : 1 : 1. The inverted PhOLED based on 0.5 nm doped EML experience significant and efficient roll‐off, with EQE from 31.1% at 100 cd/m 2, to 24.2% at 1000 cd/m 2, and finally to 17.0% at 10 000 cd/m 2, as a result of TTA effect. By increasing the thickness of EML to 10.5 nm, the efficiency roll‐off of the PhOLED was sharply reduced, with EQE from 23.3% at 1000 cd/m 2to 19.2% at 10 000 cd/m 2[111]. AIPE emitters can also be applied in the nondoped OLED emitters. Su et al. utilized AIPE‐active iridium(III)‐based molecules to fabricate OLED through solution processing. The devices can reach the maximum CE of 25.7 cd/A, and EQE of 7.6% was achieved based on this AIPE‐active complex [109]. Recently, Wu et al. took advantage of Pt(II) metal complex DPA‐Pt( Figure 1.6) with simple structure as the emitter to prepare both nondoped and doped OLED devices. The doped ones with 6% weight content showed lower EQE of 9.2%, while the nondoped ones can reach EQE of 9.8% with deep‐red/NIR emission, showing facile fabrication and high performance of the nondoped device [112]. Therefore, it could be expected that increasingly more AIPE emitters could find applications in OLED, owing to their excellent solid‐state lightening performance.

Читать дальше