This point-meshing process by the software is based on triangulation to automatically create a polygonal three-dimensional model (e.g., mesh model), which enables the design of a dental restoration on this surface. The polygonal representation of a curved shape is modeled as many small, faceted, flat surfaces. Reconstruction to a polygonal model involves finding and connecting adjacent points with straight lines in order to create a continuous surface. 5This surface model was first developed for the fabrication of solid parts by additive stereolithographic fabrication; this common file format is also referred to as Standard Tessellation Language (STL).

After defining the surface, the preparation line of the prepared teeth can be verified and marked as an outline for the restoration (design). Also, additional patient information (e.g., the jaw relationship, number of prepared teeth, restoration type, name, and tooth shade) can be added to the file. Transferring this complex information to the next step in the workflow (e.g., CAD), a referenced and calibrated digital interface is required to fully understand all relevant recipient details. Regarding this aspect, a closed (proprietary) data format from a single provider for all hardware and software components in the workflow is more maintenance-friendly compared to an open workflow involving several manufacturers. However, even if a proprietary file format is utilized, the meshing of points in clouds and their coordinates are represented as lists in the file. The advantage of a closed workflow is that the single provider will be responsible for the complete digital solution and often offers support at every step of the digital workflow. In an open workflow, the data is processed by different software and machines provided by different manufacturers. This can create problems in identifying the cause for possible errors and may raise compatibility issues. To overcome such issues in an open workflow, clinicians and technicians often rely on a “geek solution” rather than an open workflow.

A significant factor is the created size of the data set which is exported to the CAD program. In dental use, the exported surface file is not editable; only some products permit pulling and sculpturing the surface in order to manipulate the scan situation.

Accuracy

Desktop scanner accuracy can vary between devices. The ISO standard 12836:2015 describes procedures for the standardized comparison and evaluation of dental scanners. 6All available products are compliant with this standard, which is applied by the manufacturers. However, a general and independent evaluation and comparison of the accuracy of different desktop products is missing. Only a few studies cover this point of interest. 3According to the DIN ISO 5725 standard, accuracy is defined by precision and trueness. Reproducibility of results within a group is referred to as precision. Comparison with a reference scan is referred as trueness. 7

Multiple factors can influence both aspects. In desktop scanning technology, the trueness to the original prepared tooth or a primary component (bar, double-crown) is significant. By applying optical-stripe light projection, reflection and intrusion of the light onto and into the surface must be eliminated. To accomplish this, the object to be scanned is either made from a nonreflective material, or its surface is conditioned and coated by a scan powder. The first option is favorable because the powdering procedure can be error-prone, leading to measurement mistakes. In addition, all results that are based on an impression and accompanying stone cast are susceptible to the inaccuracy inherent to the conventional workflow.

Using a striped light scanner (D250, 3Shape A/S, Copenhagen, Denmark) without powder, Flügge et al. evaluated the precision of virtual models rendered from repeated cast scanning. 8The average deviation between the virtual models was 10 µm (median 6 µm) with a maximum of 460 µm. Lee et al. compared the trueness of scans (D800, 3Shape A/S) with and without powder (VITA CEREC, VITA, Bad Säckingen, Germany) to stone replicas (master die); the group without powder produced fewer dimensional changes in the coordinates. 9The total deviation values of scans with and without powder relative to the master die were 8.65 and 7.10 µm, respectively. In the same study, the precision of a contact probe scanner (Incise, Renishaw, Wotton-under-Edge, Gloucestershire, UK) and an optical scanner (D800, 3Shape A/S) was evaluated. The contact probe scanner produced fewer measurement errors and limits of agreement for all x-, y-, and z-coordinates relative to the optical scanner, which may be due to the influence of the relatively larger standard deviation (SD) of the optical scanner’s measurement errors and limit of agreements. The total root mean square (SD) of the discrepancy was 1.58 (0.43) and 1.97 (0.12) µm for the master die and stone replica. 9These findings with the latest equipment confirm the results of previous studies using older hardware and software. 2,8,10,11However, in a study evaluating the precision of complete arch scans, DeLong achieved results of 30 µm with an optical scanner (Carl Zeiss Optotechnik, Neubeuern, Germany). 12

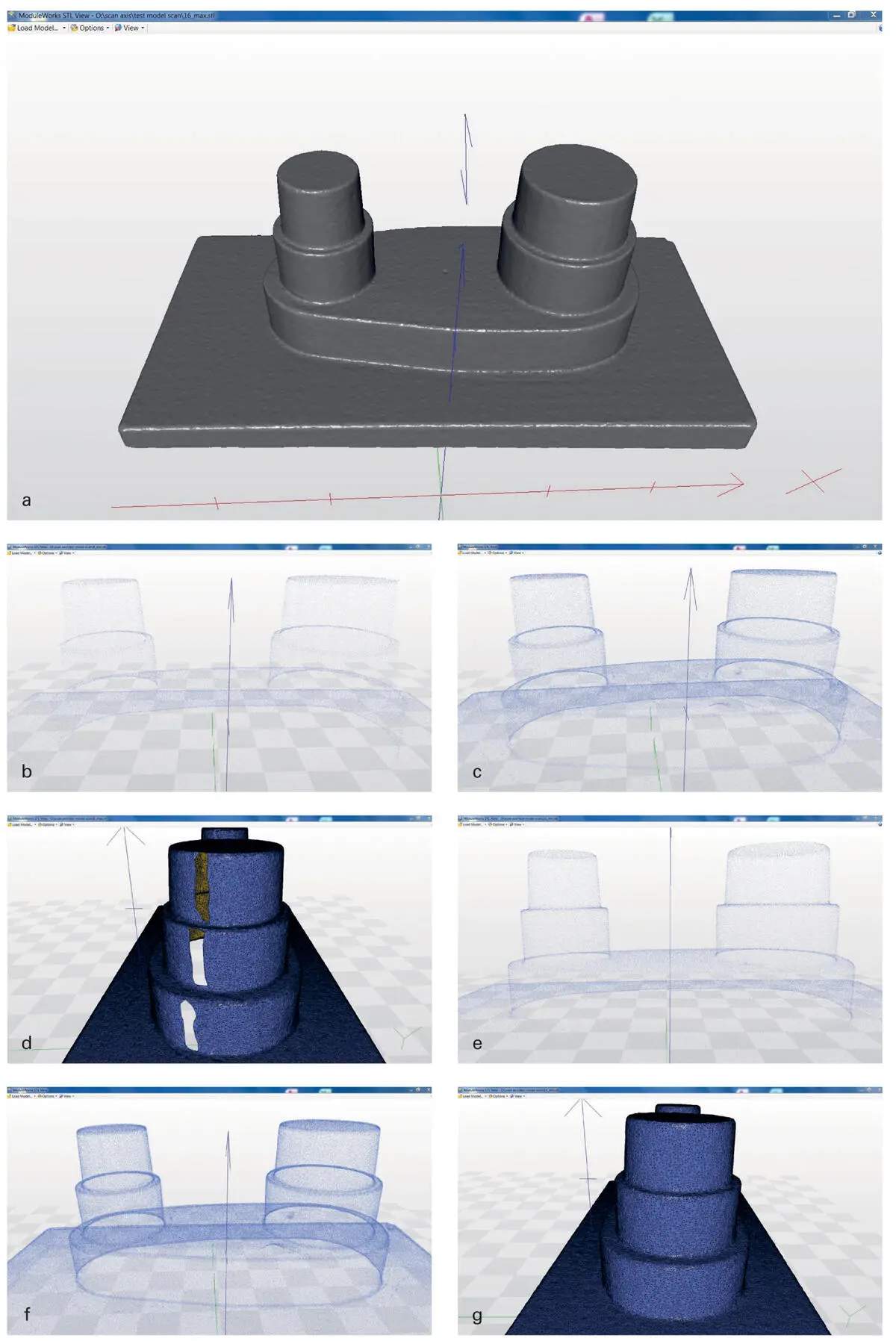

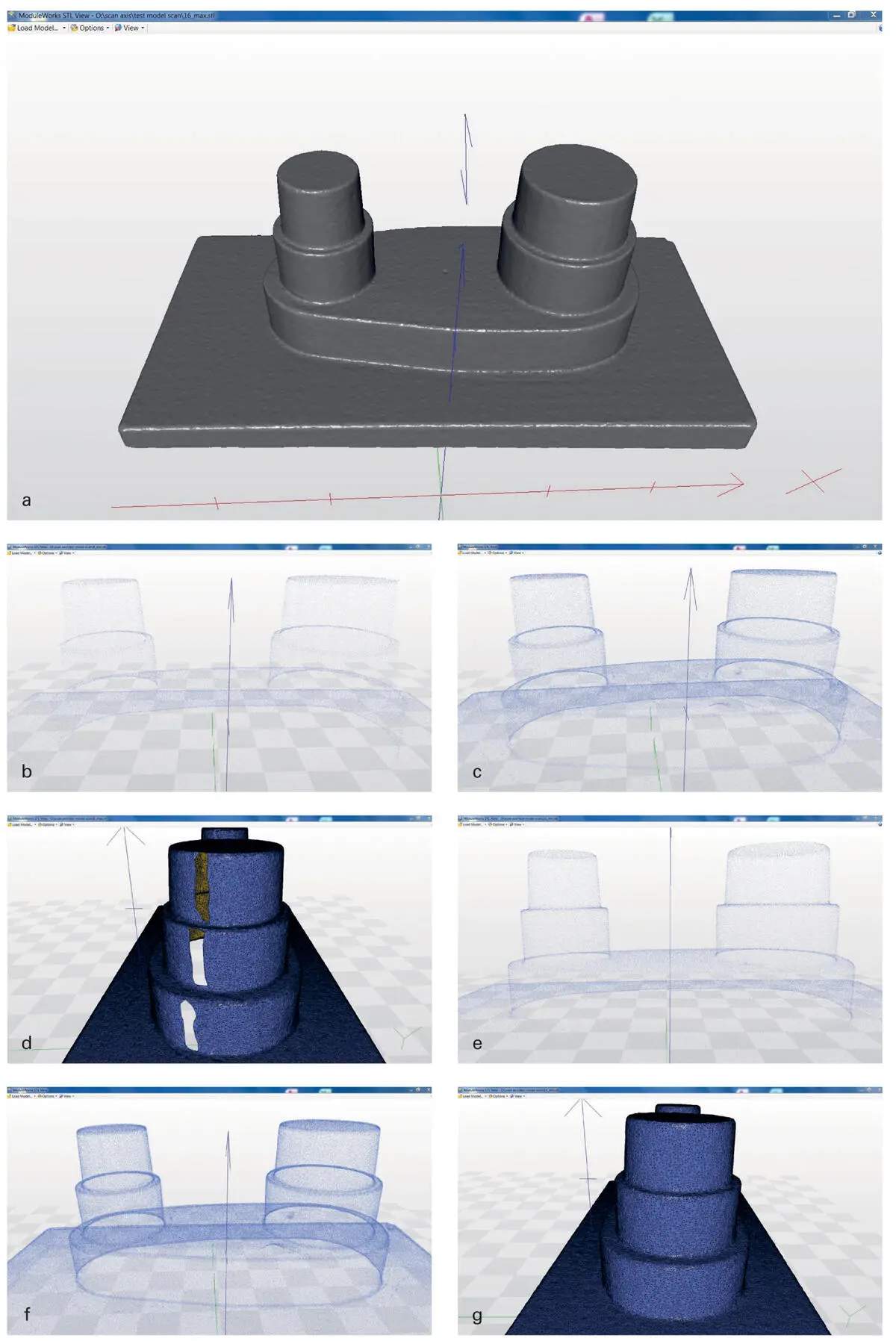

Beside the technology used and the specimen’s surface condition, the quality of the mathematical triangulation is also important. The manner in which the triangles describe the surface, particularly sharp etches and corners, is quite challenging and requires high-resolution data. This generates, in turn, large files and requires processors with high graphics capacity. The scanning software, the capacity of the computer, and the necessary accuracy need to be balanced to make a system practical and economical ( Fig 3.5). To compare clinical outcomes with respect to precision, an in vitro study was performed and the marginal adaptation of three-unit zirconia fixed dental prostheses (FDPs) obtained from intraoral digital scanners (Lava True Definition, Cadent iTero), scanning of a conventional silicone impression, and scan of a master cast with an extraoral scanner (3Shape lab scanner) was evaluated. From most to least precise: the Lava True Definition scanner showed the lowest SD gap among all groups with 26.6 μm (4.7); the master cast scan 50.2 μm (6.1); Cadent iTero scan 62.4 μm (5.0); the group of silicone impression scans produced the largest recorded mean gap with 81.4 μm (6.8). However, all groups were within the limit of clinical acceptance on the basis of a 120 μm gap. 13

Fig 3.5(a) Digital model after post-processing and meshing of the point cloud image of a model with a polygon-based solid surface. (b) Cloud of scan points with 8 scan positions at reduced resolution. (c) Cloud of scan points with 8 scan positions at high resolution. (d) Cloud of scan points and wireframe with 8 scan positions at high resolution. (e) Cloud of scan points and wireframe with 16 scan positions at reduced resolution. (f) Cloud of scan points and wireframe with 16 scan positions at high resolution. (g) Cloud of scan points and wireframe with 16 scan positions at high resolution.

Although optical-stripe light projection is the most common technology used in dental lab scanning today, laser scanning has a long tradition in scanning dental casts and impressions. These devices have been used to capture the surface topography of dental casts and alginate impressions in the orthodontic field. A laser beam scanner (R 700, 3Shape) with two cameras and three axes introduced for this application was evaluated by Lemos et al. 14The authors described an applicability of the scanner for performing measurements and analyses in orthodontics. The findings are comparable with other studies in this field 14; the same application of scanning impressions was evaluated by Kim et al. 1Scans of rubber (A-silicone) and alginate impressions were performed by a currently available device (7 series, Dental Wings, Montreal, Canada). The point clouds of the impression groups were compared with the data of the master dies. The rubber material revealed –3.0 ± 3.2 µm and the alginate 9.8 ± 6.9 µm in difference.

Читать дальше