Effect of Typical Materials of Construction on Product Color, Corrosion, Abrasion, and Catalytic Effects .

| Metals |

| Material |

Advantages |

Disadvantages |

| Carbon steel |

Low cost, readily available, resists abrasion, standard fabrication, resists alkali |

Poor resistance to acids and strong alkali, often causes discoloration and contamination |

| Stainless steel |

Resists most acids, reduces discoloration, available with a variety of alloys, abrasion less than mild steel |

Not resistant to chlorides, more expensive, fabrication more difficult, alloy materials may have catalytic effects |

| Monel–Nickel |

Little discoloration, contamination, resistant to chlorides |

Not resistant to oxidizing environments, expensive |

| Hasteloy |

Improved over Monel–Nickel |

More expensive than Monel–Nickel |

| Other exotic metals |

Improves specific properties |

Very high cost |

| Non-metals |

| Glass |

Useful in laboratory and batch system, low diffusion at walls |

Fragile, not resistant to high alkali, poor heat transfer, poor abrasion resistance |

| Plastics |

Good at low temperature, large variety to select from with various characteristics, easy to fabricate, seldom discolors, minor catalytic effects possible |

Poor at high temperature, low strength, not resistant to high alkali conditions, low heat transfer, low cost |

| Ceramics |

Withstands high temperatures, variety of formulations available, modest cost |

Poor abrasion properties, high diffusion at walls (in particular hydrogen), low heat transfer, may encourage catalytic reactions |

Source : Turton, R. et al ., Analysis, Synthesis, and Design of Chemical Processes , Prentice Hall International Series, 2001.

14 Process Planning, Scheduling, and Flowsheet Design

14.1 Introduction

Process engineering design is the application of chemical, mechanical, petroleum, gas, and other engineering talents to the process-related development, planning, designs, and decisions required for economical and effective completion of a process project [1]. Although process design engineers are organizationally located in research, technical service, economic evaluation, as well as other specific departments, the usual arrangement is to have them available to the engineering groups concerned with developing the engineering details as well as to evaluate bids for the various equipment items. Process design is usually a much more specific group responsibility in engineering contractor organizations than in a chemical or petrochemical production company, and the degree of distinction varies with the size of the organization.

The average process engineer has the following responsibilities:

1 1. Prepares studies of process cycles and systems for various product production or improvements or changes in existing production units; prepares material and heat balances.

2 2. Prepares economic studies associated with process performance.

3 3. Designs and/or specifies equipment items required to define the process flowsheet or flow system; specifies corrosion resistant materials of construction.

4 4. Evaluates competitive bids for equipment.

5 5. Evaluates operating data for existing or test equipment.

6 6. Guides flowsheet draftsmen in detailed flowsheet preparation.

The process engineer also develops tests and interprets data and information from the research pilot plant. He/she aids in scaling-up the research type flow cycle to one of commercial feasibility.

The process engineer must understand the interrelationship between the various research, engineering, purchasing, expediting, construction, and operational functions of a project. He/she must appreciate that each function may and often does affect or influence the process design decisions. For example, it is futile to waste time designing or calculating in detail, when the basic components of the design cannot be economically fabricated, or if capable of being fabricated, cannot possibly be delivered by the construction schedule for the project. Some specific phases of a project that require process understanding include plant layout, materials of construction for corrosion as well as strength, start-up operations, troubleshooting, maintenance, performance testing and so forth.

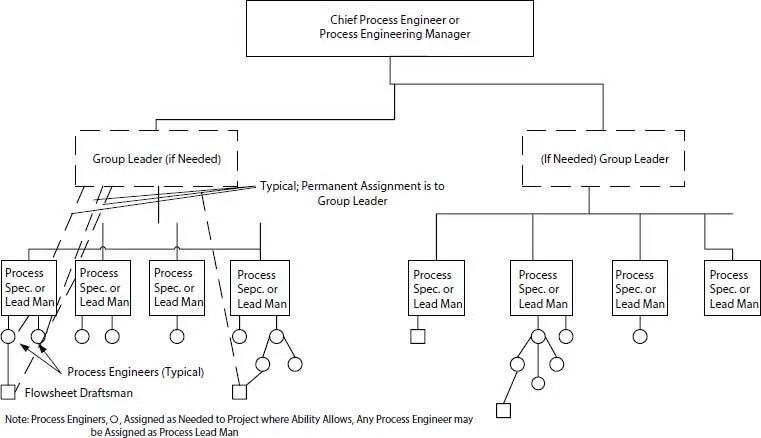

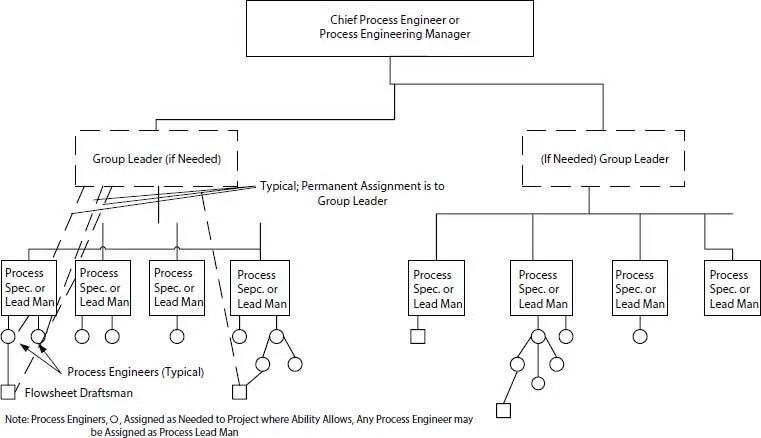

14.2 Organizational Structure

The process design function may be placed in any one of several workable locations in an organization. These locations will be influenced by the primary function of the overall company, i.e., chemical production, engineering, engineering sales, design and manufacture of packaged or specific equipment manufacture, and so on. For best efficiency, regardless of the business nature of the company, the process design being a specialty type operation, works best when specifically identified and given the necessary freedom of contact within and without the company to maintain a high level of practical, yet thorough direction.

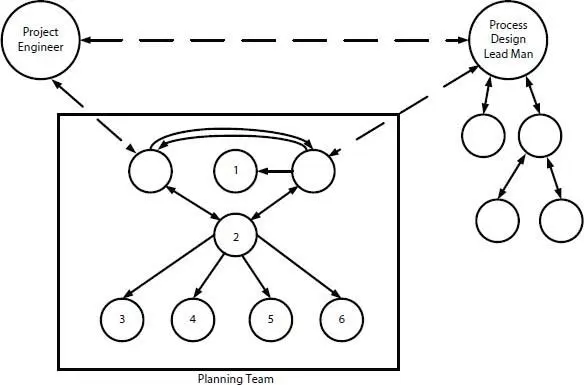

A typical working arrangement is shown in Figure 14.1[1]. In a refinery, consulting or engineering contractor organization, process design and/or process engineering is usually a separate group responsible for developing the process with the customer, or presenting the customer with a turnkey proposed process. In the case of a refinery, the process engineers in various disciplines as the crude distillation and vacuum units, aromatics and reforming units, hydrocracking units, monitor the performance of these units daily and often provide technical information should there be major upsets, mal-operation or a reduction in the performance of these units to the relevant managers who are responsible for overseeing the operation of these units.

In an operating or producing chemical or petrochemical company, the process engineering and design may be situated in a research, technical service, or engineering department. In most cases it is associated with an engineering department if new projects and processes are being planned for the company. If located elsewhere, the designs and planning must be closely coordinated with the engineering activity.

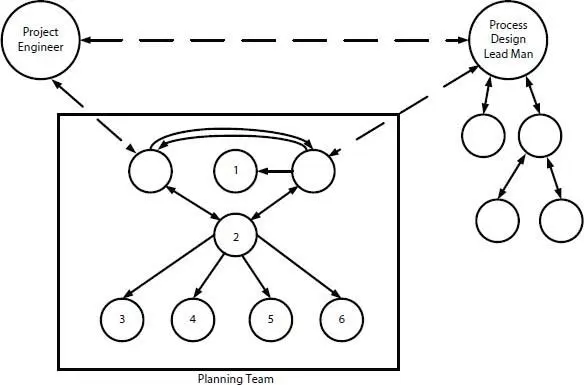

Most current thinking establishes a project team headed by a project engineer or manager to oversee the accomplishment of a given plant development for a process company. If the projects or jobs are small, then the scope of activity is limited and may often be consolidated in a single individual for project and process responsibility. For projects larger than $500,000, the project and process responsibility usually are best kept separate in order to expedite the specific accomplishment of the process design phase. When the process design engineer is required to interpret calculations and specification development and to follow some electrical, structural or even expediting delivery question or problem, the design work cannot be completed at best efficiency and often the quality of process design suffers, assuming there is a fixed target date for completion of the various phases as well as the overall project.

Figure 14.1 A process engineering section supervision chart (Ludwig [1]).

Figure 14.2 Typical organization of “engineering planning team” [2].

Читать дальше