2 2. For 3.8–38 m3 (1000–10,000 gal.), use horizontal tanks on concrete supports.

3 3. Beyond 38 m3 (10,000 gal.) use vertical tanks on concrete foundations.

4 4. Liquids subject to breathing losses may be stored in tanks with floating or expansion roofs for conservation.

5 5. Freeboard is 15% below 1.9 m3 (500 gal.) and 10% above 1.9 m3 (500 gal.) capacity.

6 6. A 30-day capacity often is specified for raw materials and products but depends on connecting transportation equipment schedules.

7 7. Capacities of storage tanks are at least 1.5 times the size of connecting transportation equipment; for instance, 28.4-m3 (7500 gal.) tanker trucks, 130-m3 (34,500 gal.) rail cars, and virtually unlimited barge and tanker capacities.

Source : The above mentioned rules of thumb have been adapted from Walas, S.M., Chemical Process Equipment: Selection and Design , copyright 1988 with permission from Elsevier, all rights reserved.

Physical Properties Heuristics.

|

Units |

Liquids |

Liquids |

Gases |

Gases |

Gases |

|

|

Water |

Organic material |

Steam |

Air |

Organic material |

| Heat capacity |

kJ/kg °C |

4.2 |

1.0–2.5 |

2.0 |

1.0 |

2.0–4.0 |

| Density |

kg/m3 |

1000 |

700–1500 |

|

1.29 at STP |

|

| Latent heat |

kJ/kg |

1200–2100 |

200–1000 |

|

|

|

| Thermal conductivity |

W/m °C |

0.55–0.70 |

0.10–0.20 |

0.025–0.07 |

0.025–0.05 |

0.02–0.06 |

| Viscosity |

kg/ms |

0°C 1.8 × 10 −3 |

Wide Range |

10–30 × 10 −6 |

20–50 × 10 −6 |

10–30 × 10 −6 |

|

|

50°C 5.7 × 10 −4 |

|

|

|

|

|

|

100°C 2.8 × 10 −4 |

|

|

|

|

|

|

200°C 1.4 × 10 −4 |

|

|

|

|

| Prandtl no. |

|

1–15 |

10–1000 |

1.0 |

0.7 |

0.7–0.8 |

Source : Turton, R. et al ., Analysis, Synthesis, and Design of Chemical Process , Prentice Hall International Series, 2001.

Typical Physical Property Variations with Temperature and Pressure.

|

Liquids |

Liquids |

Gases |

Gases |

| Property |

Temperature |

Pressure |

Temperature |

Pressure |

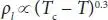

| Density |

|

Negligible |

ρ g= MW P / ZRT |

ρ g= MW P / ZRT |

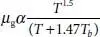

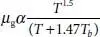

| Viscosity |

μ 1= Ae B/T |

Negligible |

|

Significant only for >10 bar |

| Vapor pressure |

P* = ae b/(T+c) |

– |

– |

– |

Note : T is temperature (K), T cis the critical Temperature (K), T bis the normal boiling point (K), MV is molecular weight, P is pressure, Z is compressibility, R is the gas constant, and P * is the vapor pressure.

Source : Turton, R. et al ., Analysis, Synthesis, and Design of Chemical Processes , Prentice Hall International Series, 2001.

Capacities of Process Units in Common Usagea.

| Process unit |

Capacity unit |

Maximum value |

Minimum value |

Comment |

|

| Horizontal vessel |

Pressure (bar) |

400 |

Vacuum |

L/D typically 2–5 |

|

| Temperature (°C) |

400 b |

−200 |

|

|

| Height (m) |

10 |

2 |

|

|

| Diameter (m) |

2 |

0.3 |

|

|

| L/D |

5 |

2 |

|

|

| Vertical vessel |

Pressure (bar) |

400 |

400 |

L/D typically 2–5 |

|

| Temperature (°C) |

400 b |

−200 |

|

|

| Height (m) |

10 |

2 |

|

|

| Diameter (m) |

2 |

0.3 |

|

|

| L/D |

5 |

2 |

|

|

| Towers |

Pressure (bar) |

400 |

Vacuum |

Normal Limits Diameter |

L/D |

| Temperature (°C) |

400 b |

−200 |

0.5 |

3.0–40 c |

| Height (m) |

50 |

2 |

1.0 |

2.5–30 c |

| Diameter (m) |

4 |

0.3 |

2.0 |

1.6–23 c |

| L/D |

30 |

2 |

4.0 |

1.8–13 c |

| Pumps |

| Reciprocating |

Power d (kW) |

250 |

<0.1 |

|

|

| Pressure (bar) |

1000 |

|

|

|

| Rotary and positive |

Power d (kW) |

150 |

<0.1 |

|

|

| Displacement |

Pressure (bar) |

300 |

|

|

|

| Centrifugal |

Power d (kW) |

250 |

<0.1 |

|

|

| Pressure (bar) |

300 |

|

|

|

| Compressors |

| Axial, Centrifugal + Recipr. |

Power d (kW) |

8000 |

50 |

|

|

| Rotary |

Power d (kW) |

1000 |

50 |

|

|

| Drives for compressor |

| Electric |

Power e (kW) |

15,000 |

<1 |

|

|

| Steam turbine |

Power e (kW) |

15,000 |

100 |

|

|

| Gas turbine |

Power e (kW) |

15,000 |

10 |

|

|

| Internal combustion eng. |

Power e (kW) |

15,000 |

10 |

|

|

| Process heaters |

Duty (MJ/h) |

500,000 |

10,000 |

Duties different for reactive heaters/furnaces |

|

| Heat exchangers |

Area (m 2) |

1000 |

10 |

For Area <10 m 2use |

|

| Tube Dia. (m) |

0.0254 |

0.019 |

double-pipe exchanger |

|

| Length (m) |

6.5 |

2.5 |

|

|

| Pressure (bar) |

150 |

Vacuum |

For 150 < P < 400 bar |

|

| Temperature (°C) |

400 b |

−200 |

need special design |

|

aMost of the limits for equipment sizes shown here correspond to the limits used in the costing program (CAPCOST.BAS).

b Maximum temperature and pressure are related to the materials of construction and may differ from values shown here.

c For 20 < L/D < 30 special design may be required. Diameter up to 7 m possible but over 4 m must be fabricated on site.

d Power values refer to fluid/pumping power.

e Power values refer to shaft power.

Source : Turton, R. et al ., Analysis, Synthesis, and Design of Chemical Processes , Prentice Hall International Series, 2001.

Читать дальше