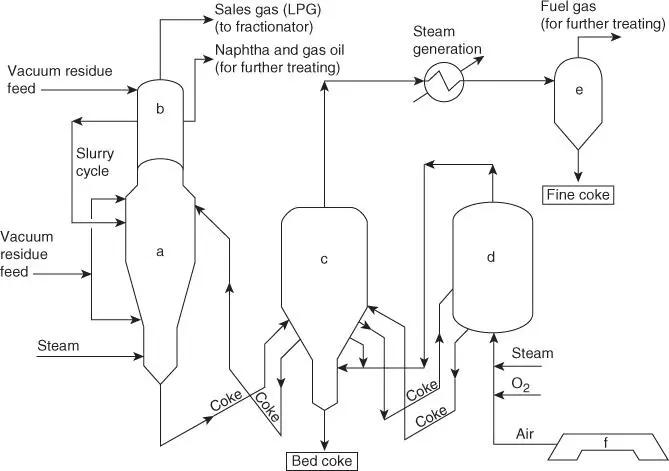

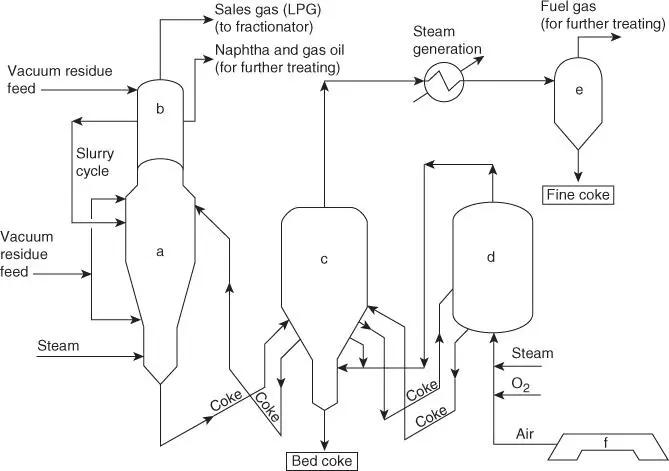

Figure 6.1.2.7 Flow sheet of flexicoking. (a) Reactor. (b) Scrubber. (c) Heater. (d) Gasifier. (e) Cyclones. (f) Airblower.

About 27% of the petroleum coke derived from delayed coking processes is calcined for use in downstream aluminum and steel production. The amount of calcined petroleum coke produced worldwide was 28 × 10 6t/a in 2013. Calcination includes the elimination, burning, and coking of water and higher‐boiling hydrocarbons contained in petroleum coke. Finally a carbon product remains that contains sulfur and nitrogen plus small amounts of vanadium, nickel, sodium, calcium, iron, and silicon.

Calcining was carried out at about 40 calciner sites in 2005 (see Table 6.1.2.4). While the calciners in North America are usually run by independent companies or attributed to aluminum production, the calciners in other regions are production units of the refineries.

At present 66% of the calcining capacity are controlled by merger (biggest: Rain C II Carbon and Oxbow Calcining), 25% by Aluminum works/Smelter (Aluminum Bahrain, Alcan Inc., JSC Bratsk), and 9% by Refineries (ConocoPhillips, BP).

Calcining is mostly carried out in rotary kiln and rotary hearth plants. While the rotary kiln largely predominates in America, some hearth plants are used in Europe. Generally the kiln type is the technology of choice. Shaft kilns are starting to be used mostly in China.

In both types of rotary calcining complexes, the water and VCM contents of green coke are eliminated by heating up to 1200–1350 °C. The heat required for calcining the green coke is primarily provided by burning the VCM released from the coke calcination process. Combustion air is admitted to the calciner. In normal operation only the quantity of air needed for the complete combustion of the VCM release from the coke is added; no free oxygen occurs in the off‐gas.

Table 6.1.2.4 Petroleum coke calciners [25].

| Owner |

Location |

State |

Type |

Production capacity (10 3t/a) |

| North America |

| Alcan |

Arvida |

Quebec |

Kiln |

215 |

| Alcan |

Kitimat |

British Columbia |

Kiln |

80 |

| Alcan/Intalco |

Edmonton |

Alberta |

Kiln |

165 |

| Arco |

Cherry point |

Washington |

Hearth |

675 |

| Arco |

Los Angeles |

California |

Kiln |

315 |

| Calciner Industries |

Chalmette |

Louisiana |

Kiln |

200 |

| Calciner Industries |

Gramercy |

Louisiana |

Kiln |

230 |

| Calciner Industries |

Norco |

Louisiana |

Kiln |

170 |

| Calciner Industries |

Purvis |

Mississippi |

Kiln |

80 |

| Conoco |

Lake Charles |

Louisiana |

Kiln |

260 |

| Great Lakes Carbon |

Enid |

Oklahoma |

Kiln |

470 |

| Great Lakes Carbon |

Port Arthur |

Texas |

Kiln |

635 |

| Kaiser Aluminum |

Mead |

Washington |

Kiln |

80 |

| Landmark Petroleum |

Fruita |

Colorado |

Kiln |

240 |

| Reynolds Metals |

Baton Rouge |

Louisiana |

Kiln |

620 |

| Reynolds Metals |

Lake Charles |

Louisiana |

Kiln |

200 |

| Union Chemicals |

Rodeo |

California |

Kiln |

295 |

| Venco |

Lake Charles |

Louisiana |

Kiln |

400 |

| Venco |

Moundsville |

West Virginia |

Kiln |

400 |

| South America |

| Copetro |

La Plata |

Argentina |

Kiln |

200 |

| Petrocoque |

Cubatao |

Brazil |

Kiln |

400 |

| Africa |

| Egyptalum |

Nag Hammadi |

Egypt |

Hearth |

135 |

| Asia/Oceania |

| Government |

Unknown |

China |

Kiln |

455 |

| KOA Oil |

Marifu |

Japan |

Kiln |

115 |

| Petrocokes |

Mizushima |

Japan |

Kiln |

80 |

| Various |

Various |

India |

Kiln |

240 |

| Pertamina |

Dumai |

Indonesia |

Kiln |

270 |

| Europe |

| Conoco |

Immingham |

United Kingdom |

Kiln |

1500 |

| OMV |

Burghausen |

Germany |

Hearth |

200 |

| Esso AG |

Karlsruhe |

Germany |

Hearth |

130 |

| Government |

Sisak |

Yugoslavia |

Kiln |

50 |

| Government |

Various |

CIS |

Hearth/kiln |

2015 |

| Rafinor |

Mongstad |

Norway |

Hearth |

170 |

| Repsol |

La Coruna |

Spain |

Hearth |

180 |

| BP |

Gelsenkirchen |

Germany |

Kiln |

200 |

| BP |

Lingen |

Germany |

kiln |

130 |

The yield of calcined coke per ton of green coke varies from 75 to 85 wt% (dry basis) depending on the technology used.

The worldwide calcination capacities distribute to the calciner types: rotary kiln calciner about 85% and rotary hearth calciner and shaft kiln calciner each about 7–8.

6.1.2.3.2.1 Rotary Kiln Calciner

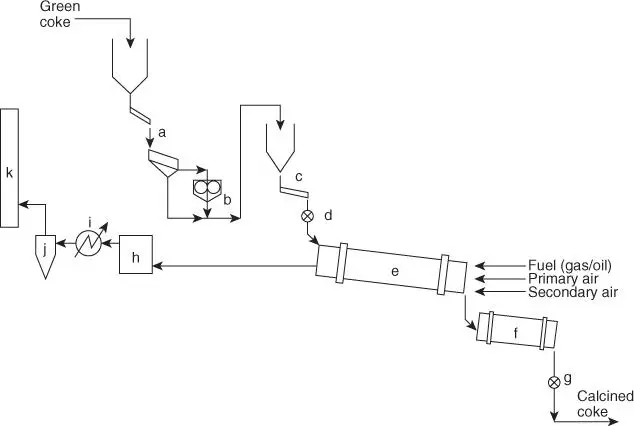

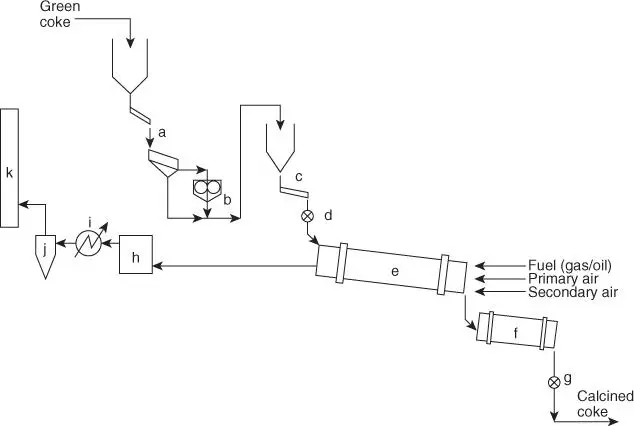

The rotary kiln calciner ( Figure 6.1.2.8) consists of a rotating heated steel tube (e) with a refractory lining. Because of the gradient and the rotation of the tube, the green coke descends in the calciner, and heat flow rises in countercurrent. The calcined coke leaving the kiln is discharged into a rotary cooler (f). The flue gases are cooled in a waste heat boiler (i) and cleaned in an electrostatic precipitator (j).

Figure 6.1.2.8 Schematic of the rotary kiln calciner. (a) Screen. (b) Crusher. (c) Weigh feeder. (d) Green coke sampling. (e) Rotary kiln. (f) Cooler. (g) Sampling calcined coke. (h) Incinerator. (i) Heat exchanger. (j) Electrostatic precipitator (ESP). (k) Stack.

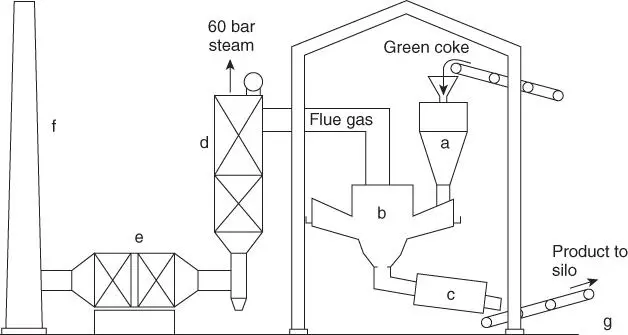

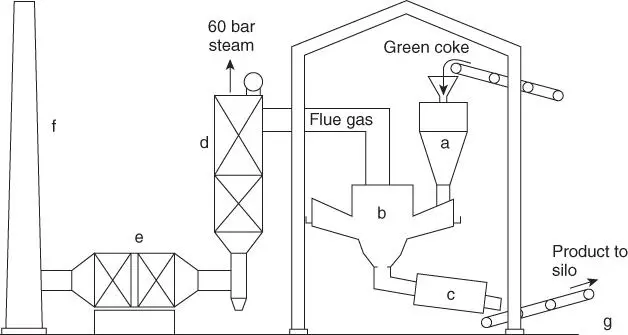

Figure 6.1.2.9 Schematic of the rotary hearth calciner. (a) Feed bin. (b) Rotary hearth. (c) Calcinate cooler. (d) Waste heat boiler. (e) Electrostatic precipitator. (f) Stack. (g) Sampling point calcined coke.

6.1.2.3.2.2 Rotary Hearth Calciner

The rotary hearth calciner ( Figure 6.1.2.9) was originally developed by the Wise Coal and Coke Company. Green coke charged at the periphery of the hearth travels around the calciner (b) in a series of concentric paths. At the completion of each revolution, the coke is moved by a rabble arm set in the roof into the next concentric path. This process is repeated, until at the final rabble, the coke is discharged into the soaking pit. From the soaking pit the coke can be discharged into a rotary cooler (c). During normal operation the retention time for the coke in the hearth and soaking pit is approximately two hours [26].

Читать дальше