1 Who owns the data?

2 Who gets access and controls permissions to the data lake for which kind of data?

3 Will these original data from the Things replace the different labels, barcodes, and other storage technology in use today?

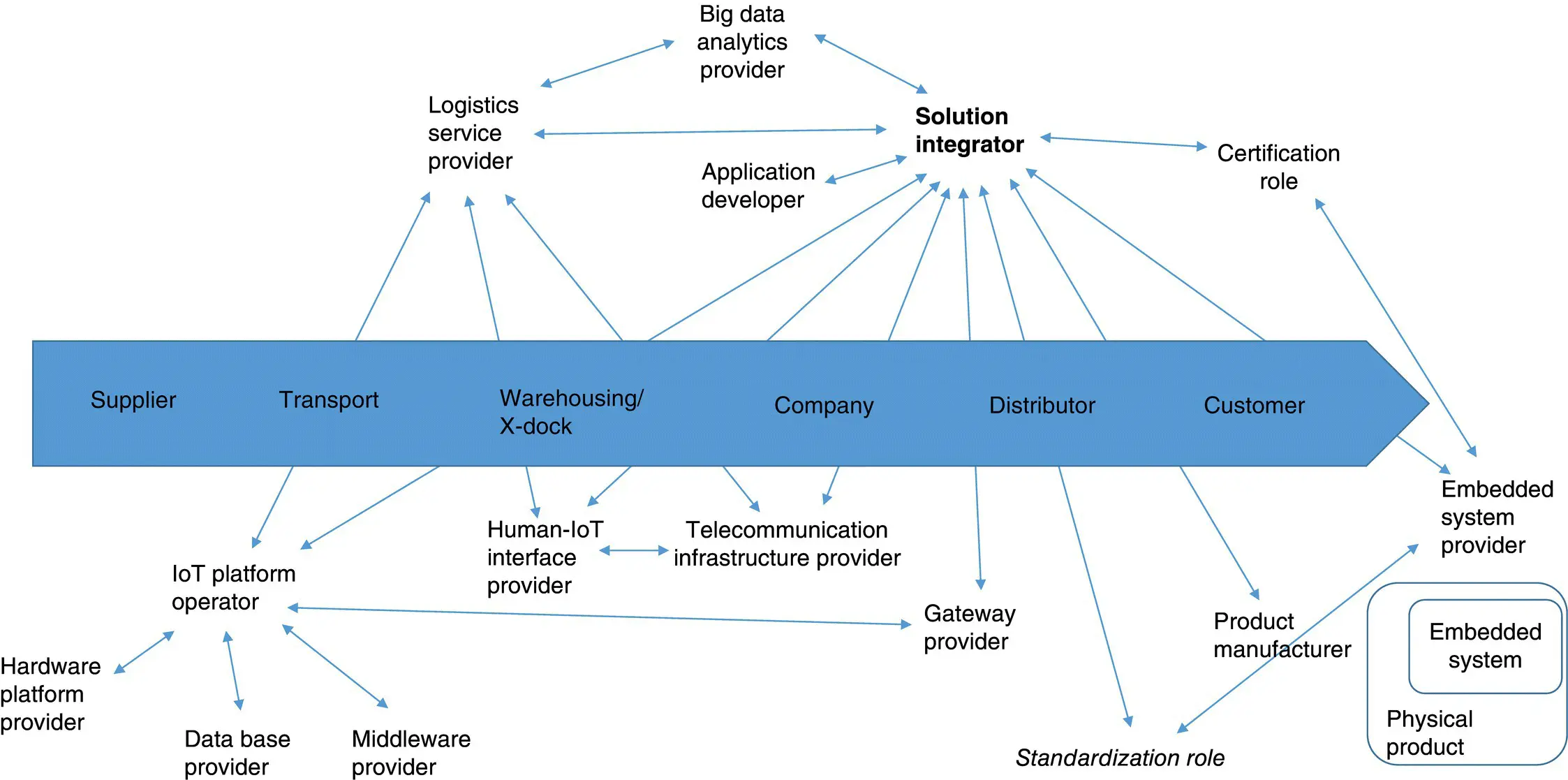

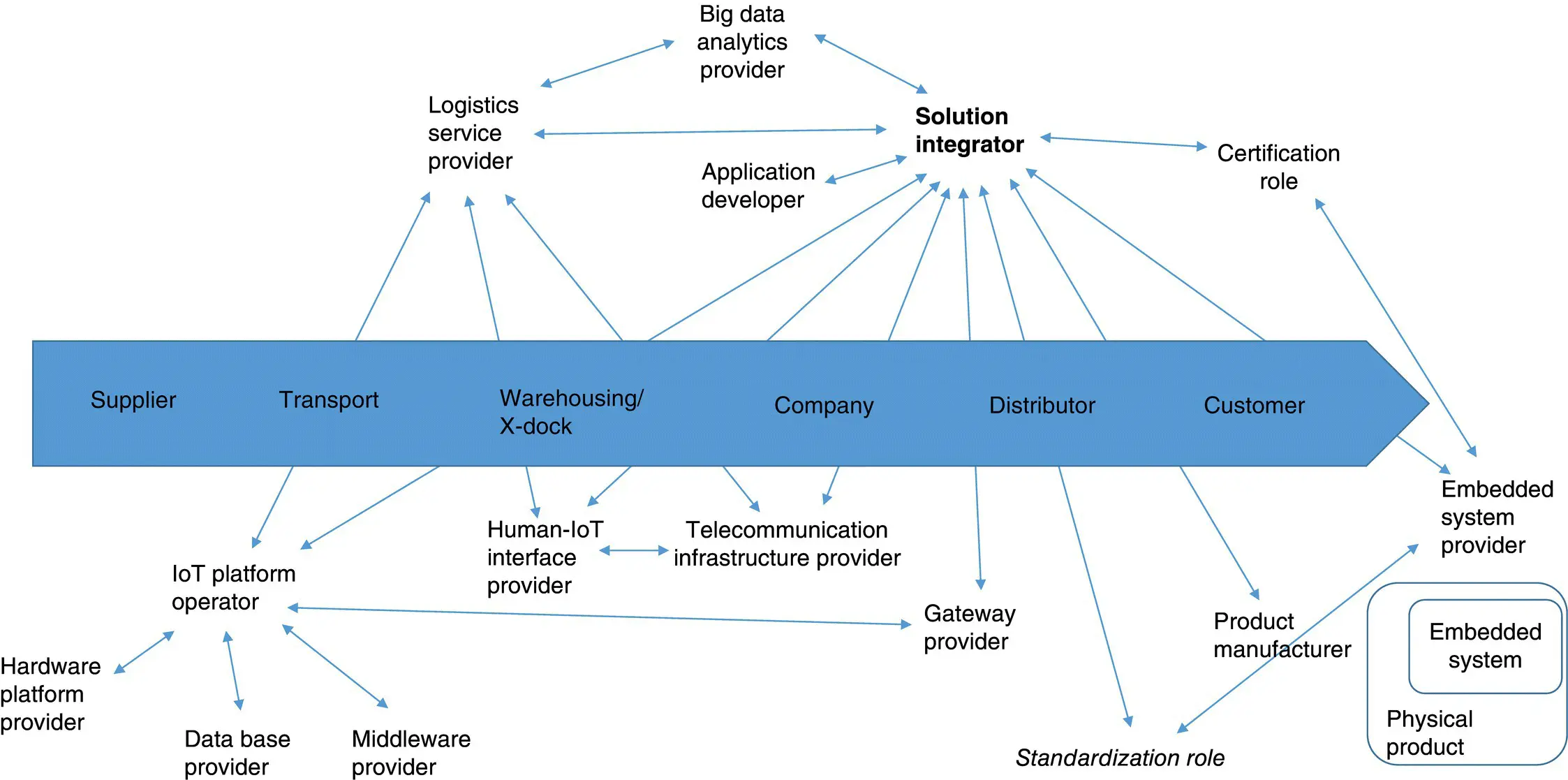

The ownership of the data might change the role of the supply chain manager and the current logistics service provider. Some big OEM customers might be the driver of the implementation of IoT logistics solutions, some logistics service provider might see some new business opportunities, but the full success of IoT logistics will only come in a connected IoT ecosystem. One example of such an IoT logistics service provider and IoT ecosystem can be seen with Alibaba’s Cainiao that operates a logistics network in China (Chou 2019). Cainiao is managing the supply chain and associated express delivery companies such as STO Express, Yunda Express, YTO Express, or ZTO Express (Wang 2018). Based on the big data of the parent company, the Cainiao network uses its own IoT platform for standardized communication and collaboration with the associated companies, which allows using IoT devices and robots in all of its warehouses and deliveries.

The target of logistics management in an IoT world is still the same as before: managing material and information flows. With smart devices (Things) connecting everything with everything, the way of doing to reach this target will change. Logistics management must address new questions related to connected Things. Data must be collected in order to be able to analyze it, so that decisions can be made. New IoT ecosystems consisting of a lot of new players must be managed.

Beside the Things, the major topic of logistics in an IoT world will be the big data generated by the Things. The major challenge will be how to use and share this data in an IoT ecosystem most efficiently and effectively. Standards, trust, and connectivity will play a crucial role.

Figure 3.4 IoT ecosystem.

Source : Based on Papert and Pflaum (2017). © John Wiley & Sons.

The connected world will offer new possibilities of doing business in terms of providing sensors for track and trace services, offering sensor‐based preventive maintenance and repair services, and helping companies to reach their logistics goals in terms of cost, lead time, and quality in a better way. This also requires new skills and a mindset change. Logistical process know‐how has to be combined with data analytics and technology. Lastly, cross‐functional collaboration, especially with internal or external IT teams, will be a crucial success factor.

The use of more smart and connected Things will enable the supply chain to implement an increasing number of automated processes. Things in the supply chain triggers the automated goods receiving, putaway and transport, commissioning, and packing of boxes and pallets for the next customer order. All devices in the physical world will be represented as a “digital twin” in the digital world. In addition to the already known classical 3D models or computer simulations, the digital twin is a virtual model of the real Thing based on “sensed” real‐life data. Design, operation, and optimization of logistical processes, infrastructure, or global supply chains can be done based on the digital twin either in real‐time or as a simulation of different scenarios (Gesing and Kückelhaus 2019).

The implementation of IoT logistics and automation solutions requires substantial investments in hardware like RFID gates, barcode readers, AGVs, smart racks, and Wi‐Fi, as well as the corresponding software and IT infrastructure. 7 For all investments in IoT, logistics management has to show a clear calculation on the expected return of investment (ROI). Reducing costs, most likely personnel, on the one hand, and increasing revenues through new and better services, on the other hand, will be the major driving factors in this calculation.

As in every transition phase from old technologies to new ones, there is a certain time period where it is necessary to handle both worlds. This also applies for IoT. Logistics management in an IoT world must ensure that the IoT ecosystem can handle IoT and non‐IoT logistics at the same time although the realization of the future picture of IoT logistics must clearly be in focus. A vision for the IoT logistics of the future can be that Things will be transported, handled, and stored in an automated way by robots and controlled by self‐organizing, decentralized, smart, AI‐facilitated networks of Things.

Internet of Things (IoT) is spreading and transforming almost all sectors including logistics, manufacturing, agriculture, healthcare, or building management. IoT enables physical devices, embedded with electronics, software, sensors, actuators, and network connectivity, to collect and exchange data.

Logistics managers must understand IoT‐related technologies such as sensors, networking technology (e.g. 5G), big data, AI, autonomous robots and vehicles (e.g. drones, AGV), augmented reality (AR) and virtual reality (VR), and the overall IoT concept as well as its implications for managing material and information flows in supply chains.

As IoT is about “connection,” logistics management needs to assess how to get connected. It is important to define which “Thing” in the supply chain, e.g. a product component, finished product, box, or container, needs to be monitored by sensors and always be online.

Based on customer’s requirements, criticality of the “Things” to influence the supply chain performance, and requirements from the business model, it must be decided which Thing should be connected to enable faster and more efficient operations.

Connecting “Things” allows to gather big data that allows for better decision making in terms of time, cost, or quality than before. Logistics management must decide which data is needed, e.g. data about the on‐time delivery of products, quality of the product in transit, or security of facilities and vehicles, and how decisions should be made.

Decisions can be either manual, automated, or autonomous, with varying degrees of human intervention necessities and possibilities. In the highest level of automated decision making, AI systems will autonomously find solutions and come to decisions based on self‐learned behavioral patterns.

Logistics management in an IoT world demands new skills and a new way of thinking about how to provide the right Thing, in the right quantity, at the right time, to the right place. Such skills include data analytics, process mapping, ability to react faster, verification of AI decisions, and human–machine interaction.

Finally, logistics management must work on improving the currently often low level of data quality to enable more automated decisions and closely collaborate not only with the “classical” material flow‐related players but also IT‐related ones.

1 Bousonville, T. (2017). Logistik 4.0. Wiesbaden: Springer Fachmedien Wiesbaden (essentials) https://doi.org/10.1007/978‐3‐658‐13013‐8.

2 Chou, C. (2019). How cainiao plans to digitize China's logistics industry. https://www.alizila.com/how‐cainiao‐plans‐to‐digitize‐chinas‐logistics‐industry(accessed 17 February 2020).

3 Gesing, B. and Kückelhaus, M. (2019). Digital twins in logistics. https://www.dhl.com/content/dam/dhl/global/core/documents/pdf/glo‐core‐digital‐twins‐in‐logistics.pdf(15 March 2020).

4 Heckel, M. (2017). Skills for industry 4.0. http://www.delivered.dhl.com/en/articles/2017/02/skills‐for‐industry‐4‐0.html(accessed 8 October 2018).

Читать дальше