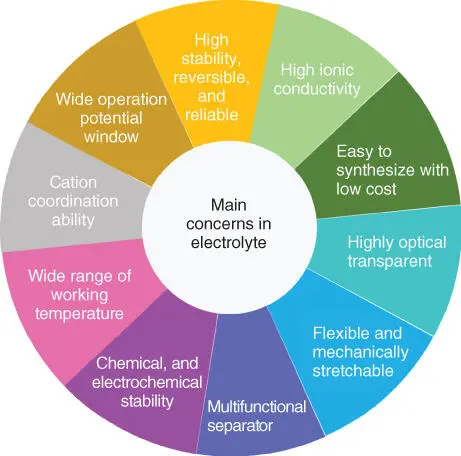

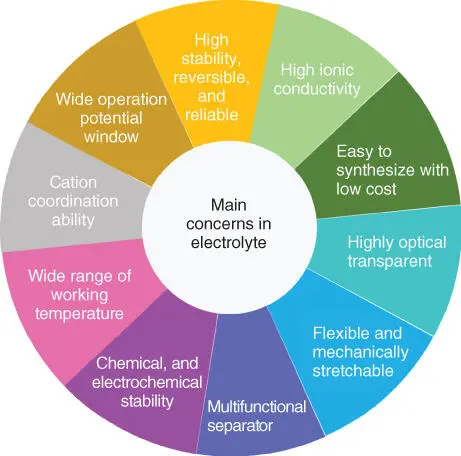

Easy to synthesize with low costThe price of PE cannot be the factor of resulting in hindering practical application. Inexpensive, easily available PEs are highly necessary for the successful commercialization and implementation of EC devices. It is worth mentioning that the thickness of PE film should be controlled and easy to operate.

Safe and environmentally friendlySafe and environmentally friendly are highly desirable for practical application of the ECDs. So far, ECDs have been widely used in people's daily lives, such as EC glasses, car mirrors, and cockpit glasses. A nontoxic, environmental, and recyclable electrolyte is a top priority in an EC device, which cannot jeopardize our health.

Figure 2.1 Main concerns in electrolyte.

2.3 Types of Polymer Electrolytes

PEs are formed by dispersing a salt into a neutral polymer matrix. The composition of the matrix plays a great role in mechanical strength, electrolyte/active material contact, flexibility, and processability in ECDs. PEs applied for ECDs can be mainly classified into gel polymer electrolytes (GPEs), self‐healing PEs, cross‐linking polymer electrolytes (CPEs), ceramic PEs, ionic liquid (IL) PEs, and gelatin‐based PEs.

2.3.1 Gel Polymer Electrolytes (GPEs)

GPE also known as plasticized PE was first introduced by Feuillade and Perche in 1975 [13]. GPEs are usually synthesized by incorporating a larger quantity of liquid plasticizer and/or solvents into a polymer matrix to form a stable gel with the polymer host structure, having relatively higher ambient‐temperature ionic conductivity [14]. Generally, GPE consists of an ionically conducting medium polymer such as poly(ethylene oxide) (PEO) and a metal salt (lithium) swollen with a suitable solvent. GPE could exhibit fast ion diffusive nature and cohesive properties comparable to solids [15]. The first one is known for its high conductivity with the H +donors originating from, e.g. sulfuric (H 2SO 4) or phosphoric (H 3PO 4) acid [16]. In the second group mobile Li +species are provided by dissolution of lithium perchlorates (LiClO 4) [17], triflates (LiCF 3SO 3) [18], fluorophosphates (LiPF 6) [19], or fluoroborates (LiBF 4) [20] in protic solvents (propylene, acetonitrile [ACN], ethylene carbonates, etc.). As was reported, binary or ternary solvents, such as EC + PC and DMC + PC + EC, were also employed [21, 22]. These types of electrolytes are characterized by a higher ambient ionic conductivity but poor mechanical properties. Although most PGEs have high ionic conductivity of 10 −3S/cm at room temperature, poor mechanical properties and considerable viscosity inevitably result in internal short circuit and cell leakage. UV and heat irradiation are other potential factors for degradation of electrolytes. Plasticizers such as PC, EC, diethyl carbonate (DEC), and dimethyl carbonate (DMC) can be applied in developing the physical characteristics of the overall blend. Plasticizers improve the ionic conductivity by increasing the amorphous phase content, dissociating ion aggregates, increasing ionic mobility within the gel electrolytes, or lowering the glass transition temperature ( T g) of the system [23]. The balance between increasing ionic conductivity and decreasing mechanical strength needs to be maintained while plasticization occurs. Gel electrolytes have been used in many applications but most of recent published papers are about EC applications. In the GPE, the immobilized solvent in the polymer matrix has strong effects on the ionic conductivity. So far, PEO, poly methyl methacrylate (PMMA), poly(vinylidene fluoride) (PVDF), poly(vinylidene fluoride‐ co ‐hexafluoropropylene) (PVDF‐HFP), and poly acrylonitrile (PAN)‐based gel electrolytes have aroused researchers' interests [24, 25]. Recently, some of gel electrolytes have aroused researchers' interests, such as poly ethylene oxide (PEO), polyethylene glycol (PEG) [26], boronate esters [27], sodium polystyrene sulfonate [28], waterborne polyurethane, [29] polyester and PEO [30], polyvinyl alcohol (PVA), PAN, PMMA, poly(ethyl methacrylate) (PEMA) and poly(2‐ethoxyethyl methacrylate) (PEO EMA), [31] poly vinyl chloride (PVC), poly(vinyl sulfones) (PVS), and PVDF [32].

2.3.1.1 PEO‐/PEG‐Based Electrolytes

PEO (with a molecular mass above 20 000 g/mol) or PEG (with a molecular mass below 20 000 g/mol) simply refers to an oligomer or polymer of ethylene oxide. PEO‐based electrolyte is the earliest and most widely studied matrix for the formation of PE. Since Armand proposed a PE based on polyethylene oxide (PEO) for lithium batteries in 1978, research in this field has been extensively carried out [33]. Polyethylene oxide (PEO) has a polar ether group and significant segment mobility. As a wide range of salt polymers, especially high lithium ion stable polymers, it has excellent compatibility [34]. But because of high crystallinity, low melting point, limited operating temperature range, low hydroxyl ion migration number, poor interface characteristics, and other shortcomings, it fails to achieve the desired effect. In PEO‐based electrolytes, the most common method of increasing ion dissociation is the use of low lattice energy salts and to add fillers, which may prevent formation of polymer crystals, resulting in fast ion transportation via an interaction between the fillers and electrolyte [35]. PEO–H 3PO 4and (PEO) 8–LiClO 4were studied for electrochromism in devices [36]. However, the low Li +conductivity inhibits its applicability. Later, PEO–Li SO 3CF 3and PEO–LiN (SO 2CF 3) 2were reported to reach higher ion conductivities [37, 38]. PEO used as electrolyte in the gel form with an ionic conductivity of 2 mS/cm was reported in WO 3film ECD, which exhibited superior EC performance and memory characteristics [39]. In addition, PEO‐based GPE plasticized with ethylene carbonate/propylene carbonate or N ‐butyl‐3methylpyridinium trifluoromethane sulfonylimide (PTFSI) has been studied by Desai et al. for the ECD [40]. Ionic conductivity can be significantly enhanced and the phase separation of the PEO and plasticizer was inhibited. Yang et al. studied the performance of the EC device prepared using poly(2,5‐dimethoxyaniline) (PDMA) and tungsten oxide (WO 3) as electrode materials and PEO‐LiClO 4as GPE plasticized with polycarbonate [41]. Similarly various other hybrid electrolytes based upon PEO were successfully applied in EC applications [42].

2.3.1.2 PMMA‐Based Polymer Electrolytes

Due to high degree of crystallization, low ionic conductivity at ambient temperature exists in PEO‐based PE [43]. PMMA along with PVDF PEs have recently caused great attention in EC application. PMMA including amorphous phase and flexible backbone could increase ionic conductivity. As was reported, PMMA can provide a high transparency, excellent environmental stability, good gelatinizing properties, high solvent retention ability, and excellent compatibility with the liquid electrolytes [44, 45]. Moreover, PMMA shows good interfacial stability toward electrodes and high solvation ability to form complexation between polymer and salt. Highly ionic conductive PMMA exists as a gel and is mainly used for electrochromism [45]. Anderson et al. majored on ECDs with films of W oxide and vanadium pentoxide and an intervening layer of a PPG–PMMA–LiClO 4[46, 47]. Reynold and coworkers first reported a polymeric ECD using poly(3,4‐proplenedioxythiophene) (PProDOTMe 2) and poly[3,6‐bis(2‐(3,4‐ethylenedioxy)‐thienyl)‐ N ‐methylcarbazole] (PBEDOT‐ N ‐MeCz) as the cathodically and anodically coloring polymers, respectively [48]. In this device, the EC films were electrosynthesized in poly (3,4‐ethylenedioxythiophene) (PEDOT)‐PSS electrodes at the oxidation potential of the monomer, and the electrolytes were prepared by using PMMA as the novel polymer matrix. The GPE having composition of 70 : 20 : 7 : 3 (ACN: PC: PMMA: TBAPF 6[tetrabutylammonium hexafluorophosphate]) was applied in the ECDs [48]. For the durability of the device, GPE was evaporated at the edges during the sealing process. The ECD exhibited a large transmittance change (Δ% T ) of 51% at the wavelength of 540 nm and only 5% contrast loss after 32 000 switches. Beaupre et al. reported a flexible EC cell by using PMMA‐LiClO4 electrolyte, which was plasticized with propylene carbonate to form a highly transparent and conductive gel. Sonmez et al. has explored a highly transparent and conductive gel with LiClO 4plasticized with PC, having composition of PC: PMMA (MW: 350.000): LiClO 4(70 : 20 : 7 : 3), which was applied in EC device [49]. ACN was also added as a high vapor pressure solvent to make the gel ingredients blend easily. Oral et al. uses similar electrolyte of LiClO4: ACN: PMMA: PC in the ratio of 3 : 70 : 7 : 20 to study the EC properties [49]. Tung et al. studied the EC properties of the device of PEDOT‐Prussian Blue (PB) using PMMA as GPE [50]. The device exhibited high coloration efficiency and good long‐term cycling stability. Recently, Yang et al. studied a new type of GPE composed of free‐standing aramid nanofibers, which was used to fabricate all‐solid‐state near‐infrared (NIR) ECDs for NIR sheltering applications [51]. This new type of GPE showed excellent mechanical and heat endurance compared with currently available GPEs. Kim et al. presented a novel ECD‐based photonic device, which can modulate IR light intensity in a planar optical waveguide ECD by using PMMA gel electrolyte consisting of 5% (w/w) PMMA, 4% (w/w) phenothiazine, 0.1 m LiClO 4, and 11.25 ≈ 10 −3m ferrocene [52]. The results confirm a new approach to consider ECD‐based optical modulators for the development of planar photonic‐integrated circuits and systems.

Читать дальше