Mechanical and Dynamic Properties of Biocomposites

Здесь есть возможность читать онлайн «Mechanical and Dynamic Properties of Biocomposites» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Mechanical and Dynamic Properties of Biocomposites

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 80

- 1

- 2

- 3

- 4

- 5

Mechanical and Dynamic Properties of Biocomposites: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Mechanical and Dynamic Properties of Biocomposites»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

A comprehensive review of the properties of biocomposites and their applications Mechanical and Dynamic Properties of Biocomposites

Mechanical and Dynamic Properties of BIocomposites

Mechanical and Dynamic Properties of Biocomposites — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Mechanical and Dynamic Properties of Biocomposites», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

1.4.1.9 Kenaf/PALF FRP Hybrid Composites

A tropical plant, pineapple ( Ananas comosus ) belongs to the family of bromeliad ( Bromeliaceae ). In South America, it is next in line to banana and mango in total production across the globe [39]. Pineapple leaf fibers (PALFs) are waste products when cultivating pineapples and are extracted from pineapple leaves. It has a significant mechanical behavior, because it is high in cellulose (70–82%) as well as in crystallinity (44–60%) [40]. Combining these properties with that of Kenaf fiber, excellent tensile and flexural strengths from FRP composite are obtained, which promises a good material for different applications [4].

Aji et al. [41] studied hybridized Kenaf/PALF specimens with HDPE reinforcement, using 1 : 1 fiber ratio. They investigated into how the size of fiber and its loadings affected the mechanical responses of the hybrid biocomposites ( Table 1.8). The four reinforcement lengths considered at a fiber loading range of 10–70% were 0.25, 0.50, 0.75, and 2.00 mm. The smallest of these fiber lengths (0.25 mm) yielded the best result in terms of its flexural and tensile properties, while both 0.75 and 2 mm exhibited enhancement in impact strength. As observed further, an increase in the fiber length reduced some of the mechanical behaviors, which is credited to the entanglement in fibers as against fiber attrition. An inverse proportionality was established between the tensile and impact properties, as the rule of mixture was satisfied by flexural strength. The adhesion between the fiber and the matrix interface was good, as evaluated by scanning electron microscopy (SEM).

Table 1.8 Mechanical behaviors of kenaf/PALF, roselle/sisal, and silk/sisal FRP hybrid composites.

Source: Nguyen et al. [4]. © 2017, Elsevier.

| Hybrid biocomposites | Fibre ratio (by weight or volume) | Flexural modulus (GPa) | Flexural strength (MPa) | Tensile modulus (GPa) | Tensile strength (MPa) | Impact strength (kJ/m 2) |

|---|---|---|---|---|---|---|

| Kenaf/PALF | 1 : 1 (At 0.25 mm fiber length and 60% fiber loading) | 4.114 | 34.01 | 0.874 | 32.24 | 6.167 |

| 1 : 1 | ||||||

| Sisal/roselle | Dry condition, fiber length = 15 cm | — | 76.5 | — | 58.7 | 1.30 |

| Wet condition, fiber length = 15 cm | — | 62.9 | — | 44.9 | 1.28 | |

| Sisal/silk | 1 : 1, fiber length = 20 mm | |||||

| Untreated | — | 46.18 | — | 18.95 | — | |

| Alkali treatment | — | 54.74 | — | 23.61 | — |

1.4.1.10 Sisal/Roselle and Sisal/Silk FRP Hybrid Composites

Sisal ( Agave sisalana) , from the Agavaceae family, is a hard‐fiber plant with wide cultivation in the tropical countries of Africa, America, and Asia, though it has its origin in Mexico and Central America. Their fibers are strong and tough, and extracted from sisal plant leaves. Sisal fibers are widely utilized in composites and plastic/paper industries. The nativity of roselle ( Hibiscus sabdariffa ) can be traced to West Africa. It is a species of Hibiscus, whose plant is naturally abundant and majorly used for fruits and bast fibers. Roselle fibers have extensive applications in the textile industry and in composites, because they exhibit greater mechanical behaviors in comparison with some other naturally occurring fibers, such as jute and kenaf.

Moreover, Athijayamani et al. [42] used a fiber ratio of 1 : 1 for the sisal and roselle fibers and investigated, under wet conditions, how absorption of moisture affected the mechanical responses of short hybrid sisal/roselle FRP unsaturated polyester composites. Using different fiber contents and lengths, their results showed an improvement (increase) in the flexural and tensile strengths of the hybrid composites of sisal/roselle fibers at increased lengths and contents of fibers and under dry condition. For the wet condition, the strengths (tensile and flexural) were significantly reduced, while inverse proportionality between the impact strength and fiber length and content was observed for both conditions (wet and dry), as depicted in Table 1.8. In addition, Noorunnisa Khanam et al. [43] also carried out a study on sisal/silk fiber ratio of 1 : 1 and prepared a polyester‐based hybrid composite to evaluate various fiber lengths. Their results showed higher mechanical (tensile, flexural, and compressive) responses from the composite sample with fiber length of 20 mm than that of 10 and 30 mm counterpart hybrid composites ( Table 1.8). Also, the results obtained after fiber modification depicted that the same mechanical behaviors of the alkali‐treated hybrid fiber composites improved significantly.

1.5 Other Related Properties that Are Dependent on Mechanical Properties

There are other properties of biocomposites that are relevant for material analysis. Some of these are dynamic mechanical properties, thermal and water absorption behaviors, as well as tribological properties. Only tribological and thermal behaviors are subsequently discussed.

1.5.1 Tribological Behavior

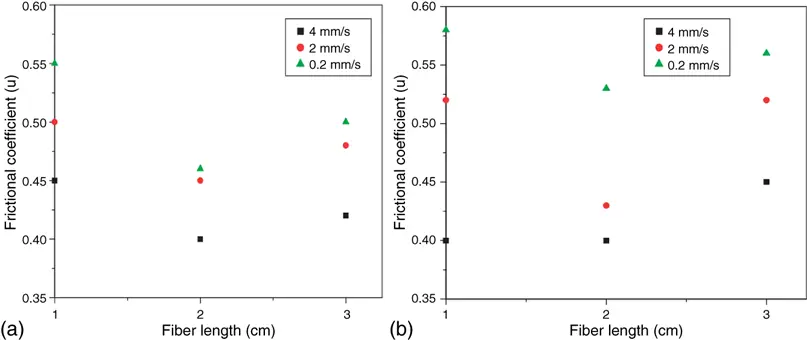

Tribological behavior refers to friction‐related properties of the materials. The frictional coefficient of hybrid sisal/glass fiber (GF)‐reinforced epoxy composites was measured by Ashok Kumar et al. [44], using different sliding speeds of 0.2, 2.0, and 4.0 mm/s, under a constant load of 10 N. At an atmospheric temperature of 22 °C and relative humidity of 45%, both alkali‐treated samples of fiber composites and untreated ones were tested. The graph of frictional coefficient against fiber length ( Figure 1.5) revealed that the frictional coefficient was lower, up to 2 cm fiber length. However, the frictional coefficient increased with an increasing composite fiber length. Moreover, fiber length addition led to a decrease in the frictional coefficient when sliding speeds were higher. The treated fiber of the reinforced composites yielded an optimum improvement at 2 cm in comparison with the untreated samples.

Figure 1.5 Frictional coefficients of (a) treated and (b) untreated sisal/glass FRP hybrid composites as a function of fiber length, after 50 cycles.

Source: Ashok Kumar et al. [44]. © 2010, SAGE Publications.

Biswas and Xess [45] studied the behavior of short bamboo/E‐GF‐reinforced epoxy hybrid composites with respect to erosion wear, using different compositions by weight as thus: 65 wt.% of epoxy, 22.5 wt.% of bamboo fiber, 22.5 wt.% of GF; 70 wt.% of epoxy, 15 wt.% of bamboo fiber, 15 wt.% of GF; and 75 wt.% of epoxy, 7.5 wt.% of bamboo fiber, 7.5 wt.% of GF, as well as 100 wt.% epoxy. The graph of the result of erosion rate against impact velocity showed that the 15 wt.% bamboo/GF FRP composites possessed the lowest rate of erosion in comparison with the other composites.

1.5.2 Thermal Behavior

The thermal property is concerned with the response of hybrid FRP biocomposites to heat variation. Boopalan et al. [46] worked on hybrid raw jute/banana fiber‐reinforced epoxy composites with regard to their thermal analysis by varying the fiber weight ratio. They used ratios of 100/0, 75/25, 50/50, 25/75, and 0/100, while varying the temperature with the use of thermogravimetric analysis (TGA) and heat deflection temperature (HDT) analysis. With the TGA, the curve depicted that the 50/50 jute/banana FRP epoxy hybrid composite demonstrated greater thermal stability. There was a shift in the temperature during degradation from a value of 200 °C to a higher value of 380 °C. For the HDT, thermal property was sustained in the 50% jute with 50% banana FRP epoxy hybrid composite at the highest temperature of 90 °C in comparison with other composite samples.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Mechanical and Dynamic Properties of Biocomposites»

Представляем Вашему вниманию похожие книги на «Mechanical and Dynamic Properties of Biocomposites» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Mechanical and Dynamic Properties of Biocomposites» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.