Mohamed N. Rahaman - Materials for Biomedical Engineering

Здесь есть возможность читать онлайн «Mohamed N. Rahaman - Materials for Biomedical Engineering» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Materials for Biomedical Engineering

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 80

- 1

- 2

- 3

- 4

- 5

Materials for Biomedical Engineering: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Materials for Biomedical Engineering»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

A comprehensive yet accessible introductory textbook designed for one-semester courses in biomaterials Materials for Biomedical Engineering: Fundamentals and Applications

Materials for Biomedical Engineering: Fundamentals and Applications

Materials for Biomedical Engineering — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Materials for Biomedical Engineering», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

4.2.5 Fracture of Materials

Fracture is the separation of a material into two or more pieces under an applied stress. Fracture can result from

Rapid growth of a crack through the material, a process described as fast fracture but often referred to simply as fracture

Slow crack growth, a process described as fatigue ( Section 4.2.7).

Unless when necessary to distinguish between fast fracture and fatigue, we shall use the term facture to mean fast fracture. Fracture typically occurs by propagation of existing cracks in a material which suddenly become unstable when the material is subjected to a sufficiently high stress which may be constant or slowly varying. Often, the magnitude of this stress is equal to a significant fraction of its measured yield strength or fracture strength. In comparison, fatigue often occurs when a material is subjected to repeated stress cycles over a long period, the magnitude of the stress often being a small fraction of its measured strength.

Fracture is classified into two types, ductile fracture and brittle fracture, which depend on the mechanical response of the solid. Ductile fracture occurs in most metals (including their alloys) whereas ceramics (including glasses and glass‐ceramics) show little or no overall plastic deformation but, instead, fail catastrophically in a brittle manner ( Figure 4.6). At room temperature, some amorphous polymers, such as polystyrene for example, fracture in a brittle manner with little sign of ductility. In comparison, semicrystalline polymers and some amorphous polymers show ductile fracture to varying degrees at room temperature.

Fracture of materials is said to involve two successive steps, crack formation and crack propagation (growth), regardless of the fracture type. On the other hand, once a crack is formed, there is a marked difference in the mechanism of crack propagation and fracture between ductile and brittle fracture.

Crack Formation

Crack formation in metals subjected to a tensile stress, for example, often occurs by linking up of microvoids already present in the material, resulting in the formation of an elongated crack perpendicular to the loading direction. Ceramics often contain residual pores and crack‐like voids resulting mainly from their fabrication process ( Chapter 7). Ceramics can also develop microcracks during cooling from their fabrication temperature due to differences in thermal expansion coefficient between adjacent grains when the grains have a non‐cubic crystal structure. This difference in thermal expansion coefficient generates local stresses during cooling in much the same way that a stress develops upon cooling a sandwich structure composed of two well‐bonded metal sheets that have different thermal expansion coefficients. If sufficiently high, these local stresses can generate microcracks in the ceramic.

Crack Propagation

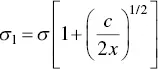

As a basis for understanding the mechanism of crack propagation and fracture in ductile and brittle materials, we can examine the local stress near the tip of a crack ( Figure 4.8). Theoretical analysis shows that the local stress σ lahead of a sharp crack of length c in an elastic solid due to an applied tensile stress σ in the Y direction is

(4.23)

where, x is the is the distance ahead of the crack tip in the X direction. The crack has the effect of amplifying the applied stress σ as the crack tip is approached. The closer the crack tip is approached, the higher the local stress σ l. Depending on the values of σ and c , σ lcan become enormous near the crack tip, considerably larger than the yield stress of a ductile metal or the theoretical strength of a brittle solid.

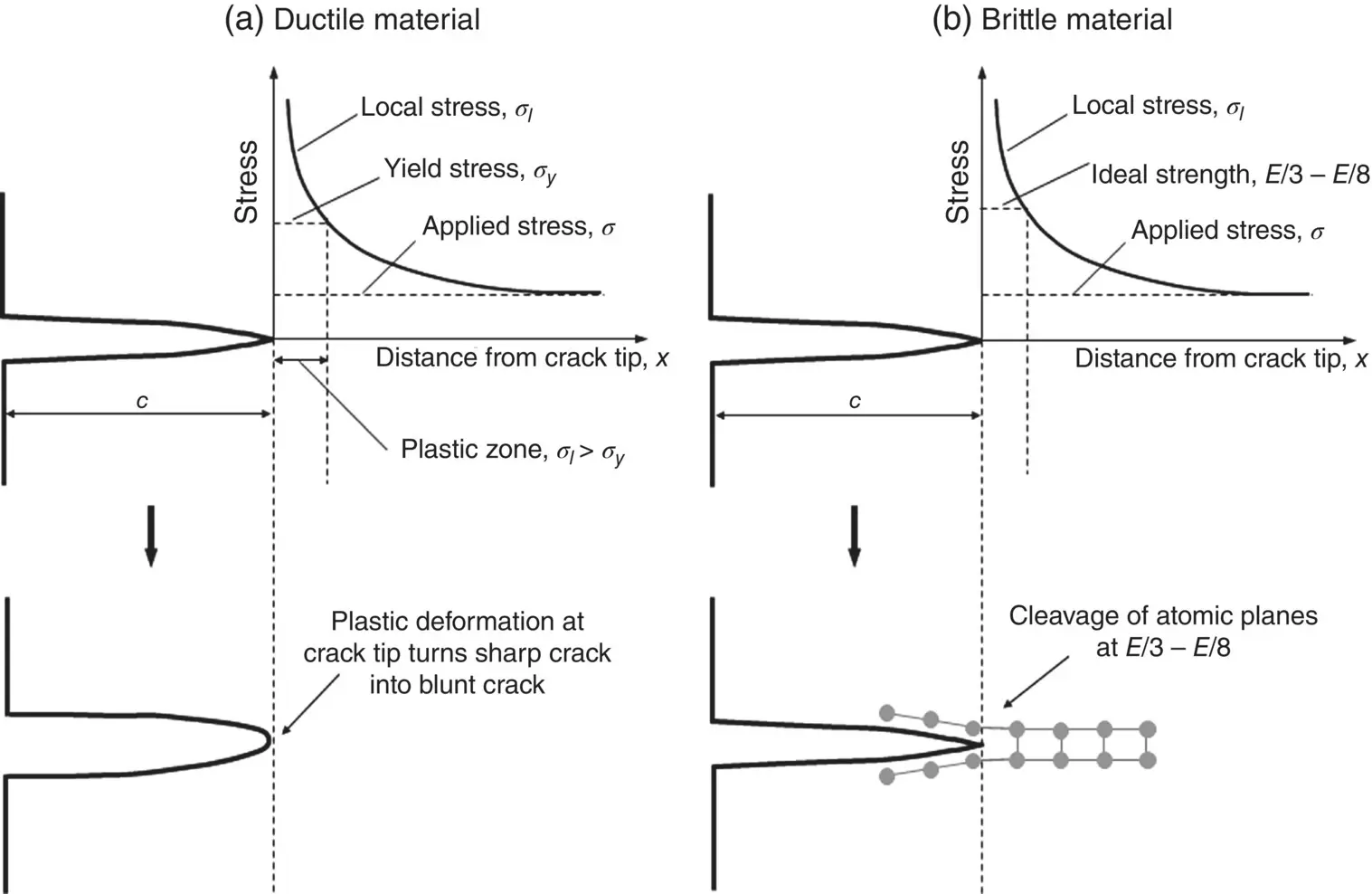

Figure 4.8 Local stress σ las a function of distance x from the tip of a sharp crack of length c in (a) a ductile material and (b) a brittle material that is subjected to an applied stress σ . If the local stress is sufficiently high, plastic flow near the crack tip of the ductile material leads to crack blunting whereas cleavage of the atomic planes can occur in brittle materials. E, Young’s modulus.

In ductile metals, as the crack tip is approached, the local stress reaches the yield stress at some distance from the crack tip. Between this distance and the crack tip, plastic deformation occurs, turning the initially sharp crack into a blunt crack. As this process consumes a significant amount of energy, the energy available for the crack to propagate further is reduced considerably. This is equivalent to saying that the material has a high toughness ( Section 4.2.6) or a high resistance to crack propagation through it. The stress at the blunted crack tip is, however, just sufficient to deform the material plastically and this, coupled with further linking up of microvoids within the metal, leads to crack growth and, eventually, to ductile failure.

In brittle materials such as ceramics, the stress at the crack tip can reach very high values because there is little or no plastic deformation to dissipate some of the energy available for crack propagation. When the local stress reaches the theoretical or ideal strength of the solid, equal to approximately E /3 to E /8, where E is the Young’s modulus, it is sufficient to break the interatomic bonds and the crack propagates rapidly between two atomic planes, a process described as cleavage. Ceramics, glasses and glass‐ceramics have low toughness or a low resistance to crack propagation when compared to ductile metals.

As ceramics almost invariably contain microstructural flaws, their measured strength in tensile or flexural loading is much lower than their theoretical strength, often by a factor of 10 2to 10 3or more, due to the high amplification of the applied stress at the sharp tips of microcracks and pores. Another feature of ceramics is that their tensile or flexural strength is also much lower than their compressive strength, often by a factor of ~5–10 or more ( Table 4.1). This is because cracks propagate more stably under compressive loads. Cracks have to twist out of their original orientation to propagate parallel to the direction of compression. Consequently, fracture does not occur by the rapid propagation of one crack (usually the largest crack) as in tensile loading. Instead, fracture in compression occurs by the slow extension of many cracks that eventually lead to crushing of the specimen.

Overall, because of the difference in crack propagation:

Metals (and other ductile materials) have approximately the same measured strength in compression and in tension

Ceramics (and other brittle materials) have a measured compressive strength that is much higher than their tensile (or flexural) strength

Consequently, proper design of structural ceramics is required to avoid their exposure to excessively high tensile stresses.

The fracture surface of ductile metals is often considerably rougher than that of ceramics or glasses due to the high degree of plastic deformation. Ceramics show a smoother fracture surface because crack propagation involves little or no plastic deformation but instead, involves cleavage of atomic planes. Another characteristic difference is that ductile fracture in metals occurs more slowly than brittle fracture of ceramics due to the energy absorbing process of plastic deformation during crack propagation.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Materials for Biomedical Engineering»

Представляем Вашему вниманию похожие книги на «Materials for Biomedical Engineering» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Materials for Biomedical Engineering» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.