Figure 1: City of Mardin: (up) a view of historical city; (down) a sketch of Mardin (After Gabriel, 2014).

The laboratory tests were performed in the rock mechanics and natural stone laboratories of the Mining Engineering Department at Dicle University, in accordance with the standards and suggestions (ISRM 1981). Thermal properties of the limestone samples were examined on specimens having edge lengths of 7 centimeters. Thermal measurements 229were conducted using ISOMET 2104 device (supplied by Applied Precision) by following the procedure described in ASTM (2014). The measurements of thermal properties were based on the analysis of the thermal response of the questioned samples to the impulses of heat flow. Measurements were conducted on all faces of the cubic samples, and the arithmetic means of the measurements were considered as the final values of thermal conductivity and volumetric heat capacity.

Results and Discussion

Limestone Decay

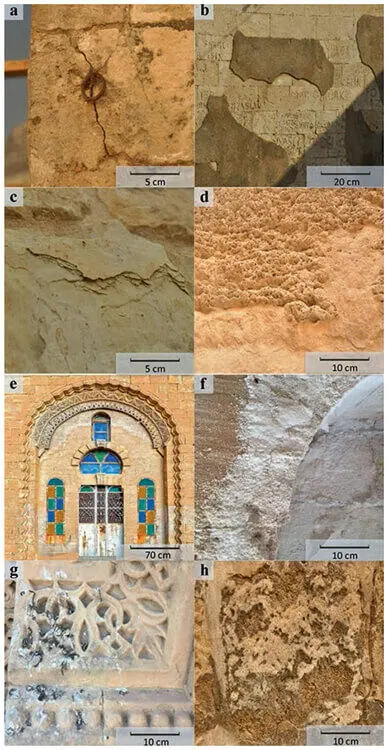

Based on the field surveys conducted at the site, it is observed that there are numerous weathering forms of various sizes and intensities on the historical structures of Mardin. The degradation features of stones are described based on the classification scheme proposed by ICOMOS (ICOMOS-ISCS 2008).

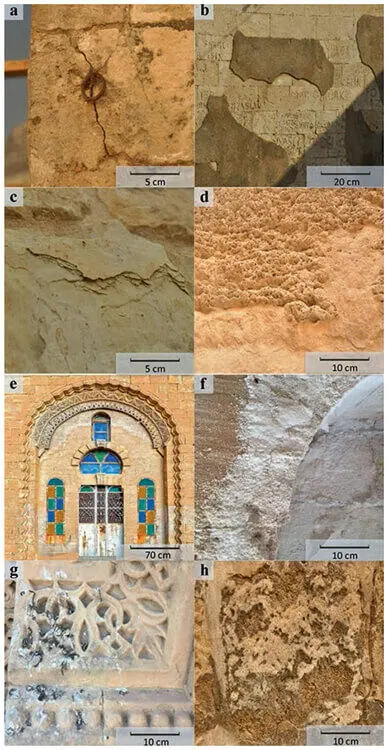

The most common weathering forms developed on the structures are defined as “cracks”, “detachments”, “material loss”, “discolorations and deposits”, and “biological colonization” (Figure 2). Most of the observed “cracks” are in the form of vertical and horizontal cracks, crack networks and fractures. “Detachments”, on the other hand, are mostly in the form of blistering, crumbling, chipping, flaking and contour scaling. “Material losses” are mostly in the form of alveolization, erosion, mechanical damage and missing part. Efflorescence, crusts, deposits, discoloration, and graffiti are widely observed “discolorations and deposits” forms of weathering. Finally, the weathering forms observed for biological colonizations are pigeon droppings, lichen, plant and algae.

In an attempt to determine the physico-mechanical properties of the stone material employed in the historical structures of the Mardin, experimental studies have been performed. The engineering properties of the limestone samples collected from a quarry in Midyat were defined and the results are tabulated in Table 1. Effective porosity and unit weight are both important engineering properties of rock material that can affect its durability. Those two index properties can be measured by the same test. The effective porosity and the dry and saturated unit weights of the limestone samples were determined using the saturation and buoyancy techniques suggested by ISRM (1981). It is understood from the measurements of 30 samples, the limestone samples have effective porosities varying from 20.44 % to 45.01 %, with an average of 35.65 % ( Table 1). The majority of the effective porosity values for the limestone samples are greater than 37 %. The ranges of dry and saturated unit weights of the samples are 14.75–20.29 kN/ m 3(with 231an average of 17.06 kN/m 3) and 19.16–22.30 kN/m 3(with an average of 20.55 kN/ m 3), respectively. According to Anon (1979), Midyat limestones have very high porosity and very low unit weight.

Water absorption is also a critical parameter that affects the durability of stone material. The water absorption behavior of a rock material is closely related to its porosity, pore size distribution and mineralogical composition (Siegesmund and Dürrast 2011). Water absorption test was conducted to calculate the amount of water that stone material can absorb under atmospheric pressure. The test was performed following the procedures suggested by RILEM (1980). During the tests, water absorptions by weight and by volume were determined for 30 limestone samples. The ranges of water absorption by weight and water absorption by volume of the limestone samples are 5.89 % to 18.29 % and 12.27 % to 27.29 %, respectively. The average water absorption by weight and by volume results for the questioned limestone samples are 11.96 % and 20.38 %, respectively ( Table 1). The UCS of the limestone samples was determined using the procedure described in ISRM (1981). The test was performed on 15 dry and 15 saturated cubic samples. The average UCS values of Midyat limestone samples for dry and saturated states are 15.15 and 9.23 MPa, respectively ( Table 1). According to the rock classifications for the strength of rocks proposed by Anon, (1979) and BSI (2015), the examined limestones are classified as “weak”.

230Through this study, the saturation coefficient of the limestones has been measured as well. This coefficient defines how much of the total pore space of a rock material is accessible to water absorption and can be used for assessment of durability (Přikryl 2013; Dursun and Topal 2019). It is the ratio between the water absorption by weight under atmospheric pressure and the water absorption by weight under vacuum pressure.

This coefficient is dimensionless and can be expressed as a decimal or as a percentage. It has been reported that a stone material with a very high saturation coefficient (i. e. greater than 0.8) may be susceptible to frost damage (Schaffer 1972; RILEM 1980; Ross and Butlin 1989). Based on the test results, it is found that the saturation coefficient of the Midyat limestones ranges between 0.50 and 0.64, with an average of 0.57, meaning that 57 % of the pores can be filled by water ( Table 1).

Based on the coefficient ranges suggested by Hirschwald (1908), the questioned samples can be classified as frost resistant.

The effect of strength reduction of stone material owing to the presence of water is a well-known fact. The effect of water saturation on rock strength has been evaluated to define the wet-to-dry strength ratio. The wet-to-dry strength ratio is also a durability parameter, defined as the ratio between the strength of rock material in wet and dry conditions. Winkler (1986) recommended that the ratio between wet and dry strength values is a rapid and reliable method for classifying rock material in terms of durability. In order to evaluate the wet-to-dry strength ratios of the Midyat limestones, the averages of the saturated and dry uniaxial compressive strength values were used. The wet-to-dry strength ratio of the examined samples was determined to be 0.61. According to Winkler (1986), the expected performance of the questioned limestones were classified as “very poor” and “poor” reflecting less durability.

Thermal properties of the natural buildng stones are important parameters since they have an influence on building climate. Especially it becomes critical while some parts of the building stones are directly exposed to solar radiation (Hall 2011). It is reported that minerals having low thermal conductivity values transmit the heat very slowly from the surface to the inner part of the stone materials (Siegesmund and Dürrast 2011). To measure the thermal properties of Midyat limestones 10 cubic samples were used. The results of the thermal properties are also tabulated in Table 1. it is found that the Midyat limestones have thermal conductivity results ranging from 1.22 to 1.93 W/mK with an average of 1.47 W/mK, and volumetric heat capacity ranging between 1.46 and 1.96 J/m 3K, with an average of 1.62 J/m 3K.

Figure 2: Some of the deterioration forms observed on Mardin Limestone (a,b) mechanical damages on different sections of the walls; (c) flaking; (d) alveolization at a upper section walls of Dara Ruins; (d) deposits-staining on a gate; (e) efflorescences on the upper left part of an arch; (g) pigeon droppings at the lower section of the wall; (h) salt crust-crumbling at the lower part of a wall.

Читать дальше