1 ...6 7 8 10 11 12 ...17 The first efforts to develop formal design methodologies for intensified processes were due to the work by Gani and his research group [34-36]. Such initial methodologies make use of the concepts of tasks and phenomena, giving rise to the concepts of phenomena building blocks (PBBs), which represent the tasks involved in a process unit such as reaction, heating, cooling, mass transfer, and so forth; the combination of PBBs provides simultaneous phenomena building blocks (SPBBs), which are used to model the operations involved in a process. For instance, in a distillation column, the following SPBBs can be observed. Each tray shows a mixture with two phases, with contact, transfer, and separation between the two phases (vapor and liquid), while the condenser adds cooling and the reboiler adds heating to the previous SPBBs, as shown in Figure 1.2for a column with five trays.

Figure 1.2Simultaneous phenomena building blocks in a conventional distillation column.

Using these concepts, Lutze et al. [36] developed a methodology for process design of intensified processes, consisting of three stages. In the first one, a basic process flowsheet is synthesized. In the second stage, SPBBs are developed and a superstructure that contains all the possible tasks of the system is formulated. The problem is then solved as a mixed‐integer nonlinear programming (MINLP) model to obtain the intensified structure that minimizes a given objective function such as the total annual cost of the system. Babi et al. [34] applied an extended formulation of that model that included sustainability metrics to a case study dealing with the production of dimethyl carbonate. In the work by Castillo‐Landero et al. [37], such a methodology was taken as a basis, but instead of formulating an MINLP model to search for the optimal intensified configuration, a sequential approach with gradual intensification of the process was conducted until a final structure with a minimum number of equipment units was obtained. One advantage of this procedure is that one can assess individual levels of process intensification so that a structure that favors a given metric of interest can be selected.

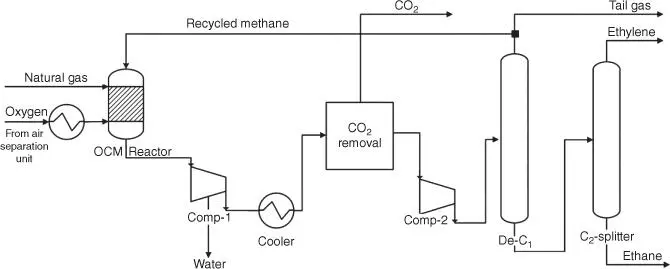

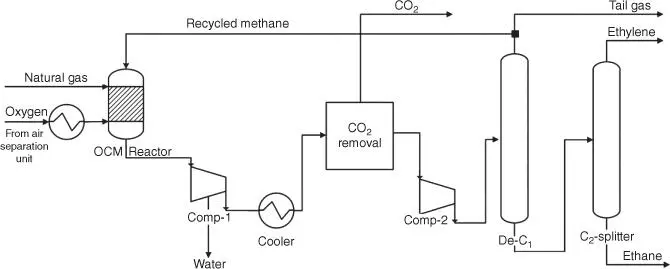

Interesting challenges arise when shale gas processes are considered for process intensification. Let us take, for instance, the basic flowsheet for the production of ethylene from shale gas, or natural gas, shown in Figure 1.3. As discussed earlier, this process shows a fairly simple structure but an adverse profitability, which poses a particular incentive to explore potential benefits that an effective process intensification task could provide. Nonetheless, noticeable challenges exist for its transformation into an intensified process that combines the process tasks, namely, reaction and several separation tasks. First of all, the reactor performs a catalytic, gas‐phase reaction task, which consists of a complex reaction mechanism. Secondly, the separation tasks consist of a combination of compression for water condensation and absorption for CO 2removal (typically carried out with an amine such as MEA). Combination of absorption and membrane could possibly be considered. The distillation train, finally, is highly energy intensive. Given the tasks identified for this process, and the aim to intensify it, the use of membrane units would be of special consideration. Membrane units could conceptually be designed first to carry out the individual tasks. Then, combinations of reaction and separation tasks based on such membrane units could be considered. The resulting structure would include innovative gas‐phase membrane‐reactive‐separation units. The design of effective membranes that, among other things, could separate the gas mixture that requires cryogenic distillation systems could provide a significant impact on the process economics. It should be mentioned that some efforts to combine reactive distillation with membrane separation have been reported (e.g. [38]). However, the reaction for which the intensification with membrane units has been considered has been typically implemented for liquid‐phase reactions. In such cases, membranes aid in improving the effectiveness of the process, for instance, by releasing one of the products of the reversible reaction to improve its yield. The problem posed by shale gas processes is the gas‐phase reaction that requires special membrane materials for its effective application. The aspects outlined here taking the OCM transformation technology as an example provide a clear incentive toward the design of more competitive alternatives based on more compact, innovative shale gas‐intensified technologies.

Figure 1.3Basic flowsheet for ethylene production from shale/natural gas.

1.12 Potential Benefits and Tradeoffs Associated with Process Intensification

Although intensification opportunities for shale gas technologies remain to be explored, it is worthy of mention its potential benefits and possible tradeoffs based on the results from research and applications of intensification methodologies. First, it could be mentioned that a direct economic impact that would favor investment and operating costs could be observed. A notable example is the intensified process design developed by Eastman Chemicals for the production of 400 kT/yr of methyl acetate that transformed a flowsheet with 10 units (one reactor and nine separation columns) into a single reactive‐distillation piece of equipment. The resulting intensified process had 1/5 of capital investment and 1/5 of energy costs with respect to the original process [39]. One could also expect improvements in other factors such as carbon footprint and global warming metrics [37]. However, tradeoffs with other aspects such as process inherent safety and process controllability remain to be assessed. In an initial work to account for process inherent safety for a case study dealing with the intensification of an isoamyl acetate process, it was found that a partially intensified process could provide a better alternative in terms of inherent safety expectations with respect to a fully intensified process [40]. On the other hand, the effect of losing degrees of freedom for process control that arises from intensifying an original process and how it affects the process operability and controllability is an item that remains to be addressed.

An analysis of shale gas availability and its potential implications to support a shale gas industry that expands its use as an energy source to include transformation processes into value‐added chemical products has been presented. Designs for shale gas transformation into valuable chemicals such as methanol and ethylene are examples of current efforts to produce higher value‐added molecules particularly valuable as precursors of important end products. The development of extraction technologies has provided the basis for the development of shale gas monetization strategies. It has been shown how the profitability of shale gas processes may be in conflict with other important considerations such as the process safety, which sets the incentive for the development of multi‐objective optimization formulations to obtain designs that offer the best compromises between such conflicting metrics. Another interesting challenge, in addition to the development of efficient and profitable shale gas flowsheets, lies in the design of intensified processes for flowsheets originally based on conventional reaction and separation units. Current intensification methodologies could be taken as a basis, with the challenge of its application for cases based on gas‐phase reactions that involve complex reaction mechanisms and different types of separation processes. The development of membrane‐based processes seems like a promising alternative in the search for innovative shale gas intensified processes.

Читать дальше