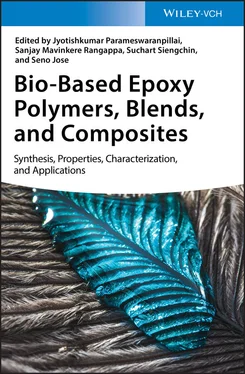

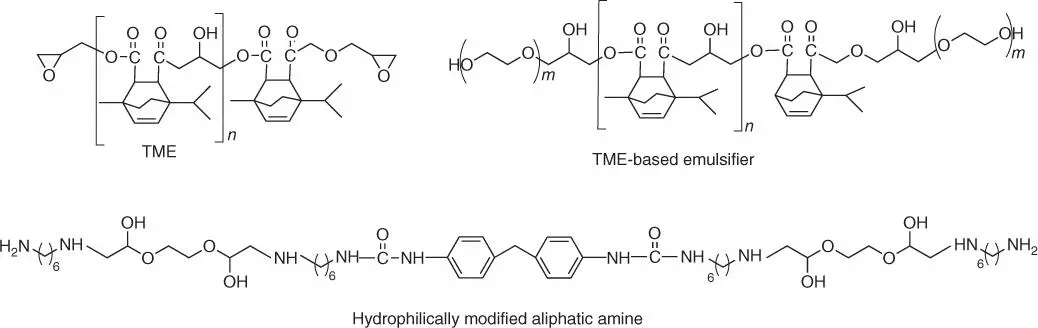

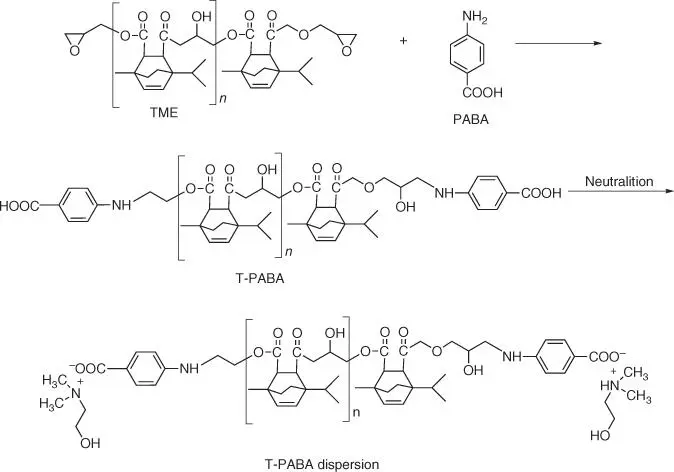

Figure 1.50 Chemical structures of TME, TME‐based emulsifier, and aliphatic amine.

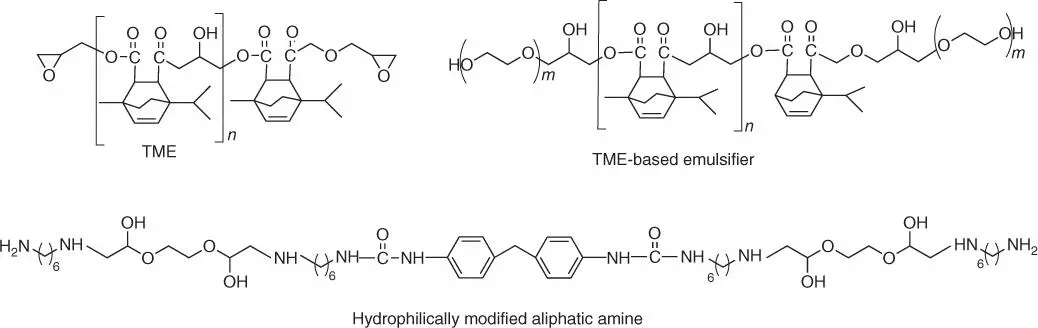

Figure 1.51 Preparation of T‐PABA and T‐PABA dispersion.

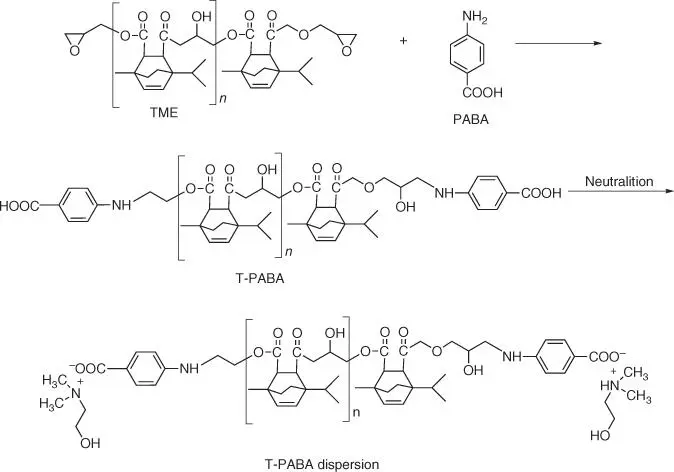

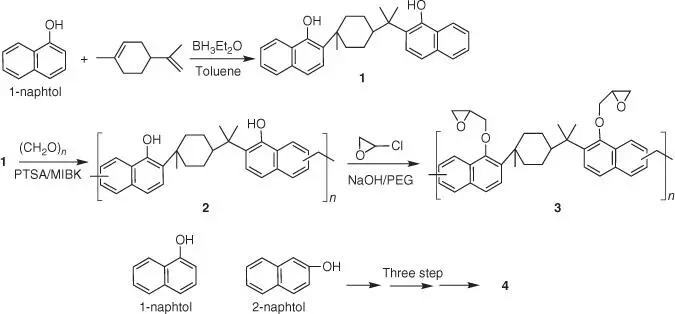

On the other hand, the oxidation of limonene, the terpene derivative, which within the structure contains two double bonds, (i) vinylene group allocated in the ring and (ii) vinylidene side group, results in limonene monoepoxide and diepoxide – compounds commercially applied as reactive diluents in epoxy applications [135]. Additionally, D‐limonene might also be used in the synthesis of epoxy resins as a bio‐based replacement for conventional DGEBA resins [136]. Hybrid epoxy resin, including naphthalene and limonene moieties, is obtained on the course of the three‐step reaction ( Figure 1.52) consisting of (i) alkylation of naphthol with limonene in the presence of Friedel–Crafts catalyst, (ii) introduction of methylene linkage between naphthalene rings to obtain product 2with higher molecular weight, and subsequently (iii) epoxidation of 2with epichlorohydrin in the presence of sodium hydroxide and polyethylene glycol to give epoxy resin 3.

The obtained epoxy resin is mixed with dicyanodiamide and a bisphenol A formaldehyde novolac resin used as curing agents in a molar stoichiometric ratio of 1 : 1 and in the presence of 2‐methylimidazole as an accelerator. Compared to DGEBA resins, the cured D‐limonene/naphthol‐based epoxy resins are characterized by higher T g(by 75 °C) and thermal stability with higher temperatures of maximum rate of weight loss in air by about 40 °C.

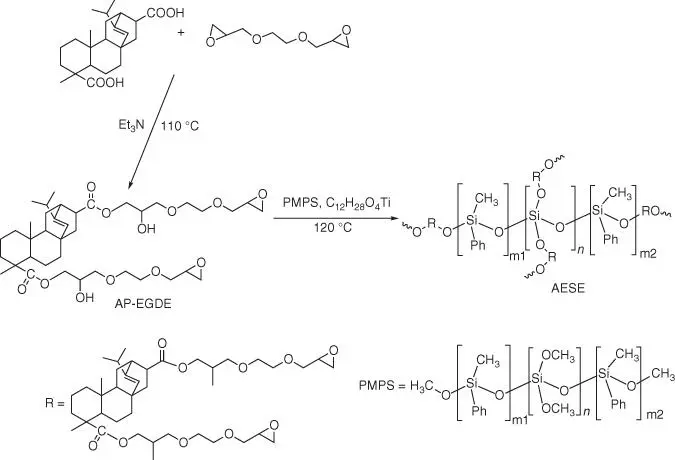

Epoxy resins might also be synthesized from rosin, produced by heating fresh tree resin to remove the volatile liquid terpenes [137]. Because of the presence of rigid hydrogenated phenanthrene ring in the molecular structure, rosin is suitable as an alternative to DGEBA [138, 139]. The interesting examples are the flame‐retardant rosin‐based epoxy thermosets, such as a rosin‐based siloxane epoxy monomer (AESE), which is prepared by the reaction of ethylene glycol diglycidyl ether modified acrylpimaric acid (AP‐EGDE) with polymethylphenylsiloxane (PMPS) ( Figure 1.53) [140].

Figure 1.52 Synthesis of epoxy resins starting from naphthol and limonene.

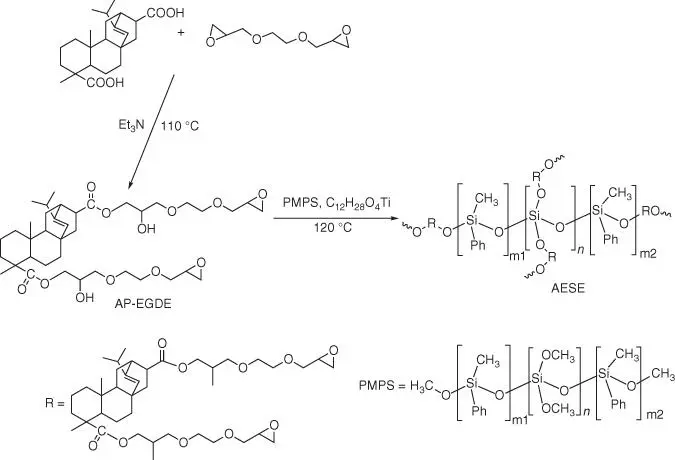

Figure 1.53 Synthetic route to a rosin‐based siloxane epoxy monomer (AESE).

The incorporation of PMPS results in the improvement in the LOI value compared to the AP‐EGDE/MHHPA thermosets. The highest LOI value of 30.2% is noted for the cured product containing 30 wt% of AESE (AESE30/MHHPA). Because of the presence of the flexible chains of the PMPS, all the AESE/MHHPA thermosets display a relatively low tensile strength ( < 15 MPa) but on the other hand much larger elongation at break ( > 50%).

Terpenes are an interesting group of raw materials that might be used in the synthesis of epoxy resins. Even though not all terpenoids contain aromatic and/or phenolic moieties, these requirements can be reached via different synthesis steps (e.g. carvacrol, for instance, might be obtained from other turpentine components, limonene, for instance, throughout an oxidation, followed by an isomerization process).

1.4 Bio‐Based Epoxy Curing Agents

Cross‐linking of epoxy resins takes place with the participation of oxirane rings present in them. The strained structure of these rings is the reason for their high reactivity and facilitates their opening under the influence of very different factors. Epoxy resin curing generally takes place under the influence and with the participation of multifunctional chemical compounds with active protons. These are mainly polyamines (aliphatic, aromatic, and cycloaliphatic) and carboxylic compounds (acids and anhydrides). Cross‐linking of the epoxy resins can also be accomplished by a mechanism of ring‐opening polymerization using suitable catalysts. This is an important method of cross‐linking, especially coating materials. However, the search for compounds of natural origin, which could replace petrochemical hardeners, is the most important in the case of polyamines and carboxyl compounds that are used for cross‐linking in stoichiometric ratios to the content of epoxy groups in the resin. The consumption of ring‐opening polymerization catalysts is insignificant compared to the polyamine and carboxylic hardeners. Usually, they are used in an amount of up to several percents by weight relative to the weight of the cross‐linked resin. Therefore, new biohardeners should be sought first and foremost among the compounds of natural origin with amine or carboxylic functionalities. The appropriate reactivity and adequate miscibility with epoxy resins are the conditions, which are limiting the use of these new compounds.

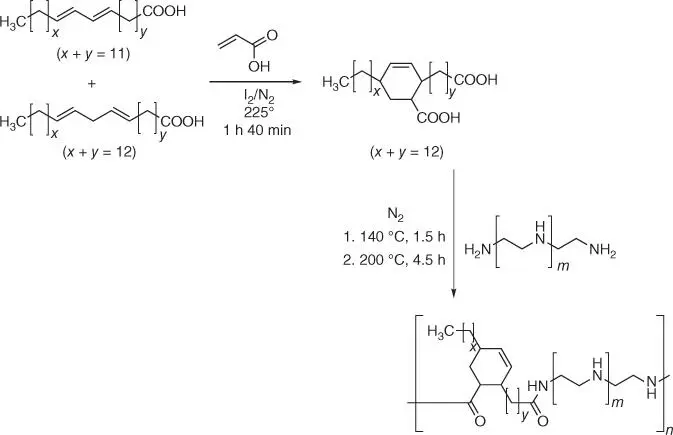

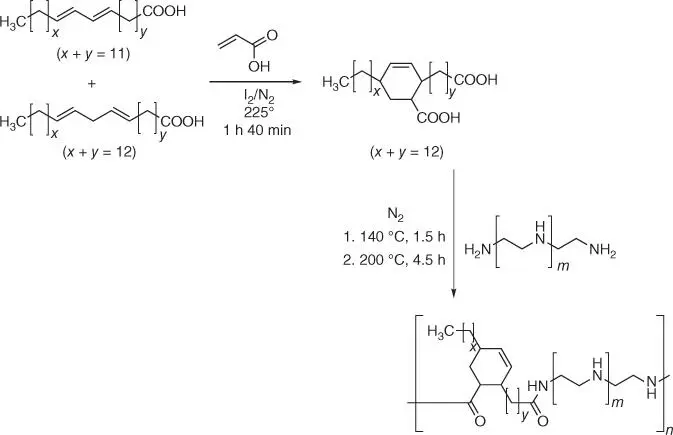

Considering the possibilities of using plant oils as raw materials for the synthesis or modification of epoxy resins, an interesting solution would be just to give the plant oils proper functionality so that they can also act as natural hardeners. The use of modified vegetable oils in this role is favored by their very good miscibility with the epoxidized vegetable oils and good miscibility with the epoxy resins based on bisphenol A (despite the differences in the polarity of both groups of materials). For example, hydrolyzed castor oil can serve as a source of dehydrated fatty acids from which reactive polyamides are obtained by reaction with acrylic acid [141] ( Figure 1.54) and then with various polyamines (diethylenetriamine, triethylenetetramine, and tetraethylenepentamine) [17].

The obtained polyamides (with amine values from 310 to 389 mg KOH/g) can be used to cross‐link the epoxy resins based on bisphenol A giving the materials with good coating properties.

Figure 1.54 Synthesis of C 21cycloaliphatic dicarboxylic acids and reactive polyamides from them.

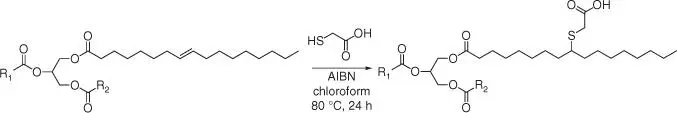

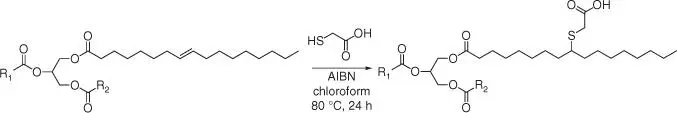

Figure 1.55 Scheme of soybean oil functionalization with thioglycolic acid.

Vegetable oil‐based curing agents can be obtained through direct oil modification. The novel bio‐based polyacid hardener is synthesized by the thiol‐ene coupling of soybean oil with thioglycolic acid ( Figure 1.55) [142].

The synthesized soybean oil‐based polyacid exhibit a functionality of 3.3 acid functions per triglyceride molecule. This polyacid curing agent is characterized by the high reactivity toward epoxy groups. The low molecular weight bisphenol A‐based epoxy resin cross‐linked with the bio‐polyacid exhibits interesting properties for coating and binders (the Shore A hardness of 52 and E′ = 0.59 MPa). A commercially available mercaptanized soybean oil (prepared by direct addition of H 2S to soybean oil) reacted with allylamine ( Figure 1.56) or its salts can also be potentially used as a cross‐linking agent for epoxy resins [143].

Читать дальше