The DAC may also be used in radial geometry to study deformation properties at high pressures. In radial diffraction, the x‐ray beam is directed through the gasket, orthogonal to the compression direction. For these experiments, no pressure medium is used so that the diamonds impose pressure and deviatoric stress to deform the material elastically and plastically. This geometry requires x‐ray transparent gaskets such as beryllium or amorphous boron (Hemley et al., 1997; Merkel & Yagi, 2005) to allow passage of the x‐ray beam across the sample. Radial diffraction technique and the DAC has now been used for around two decades to make in‐situ measurement of lattice strains and texture development at high pressure (Hemley et al., 1997; Wenk et al., 2000).

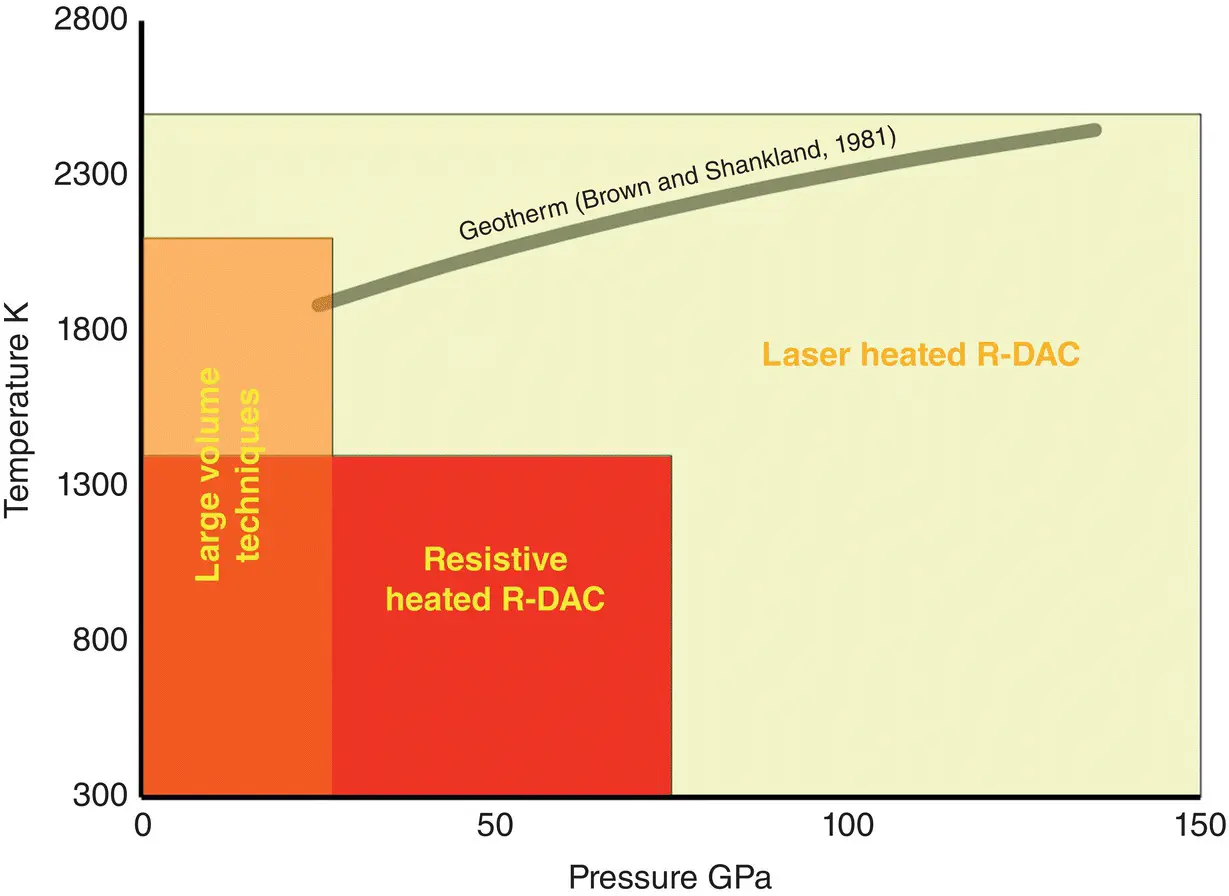

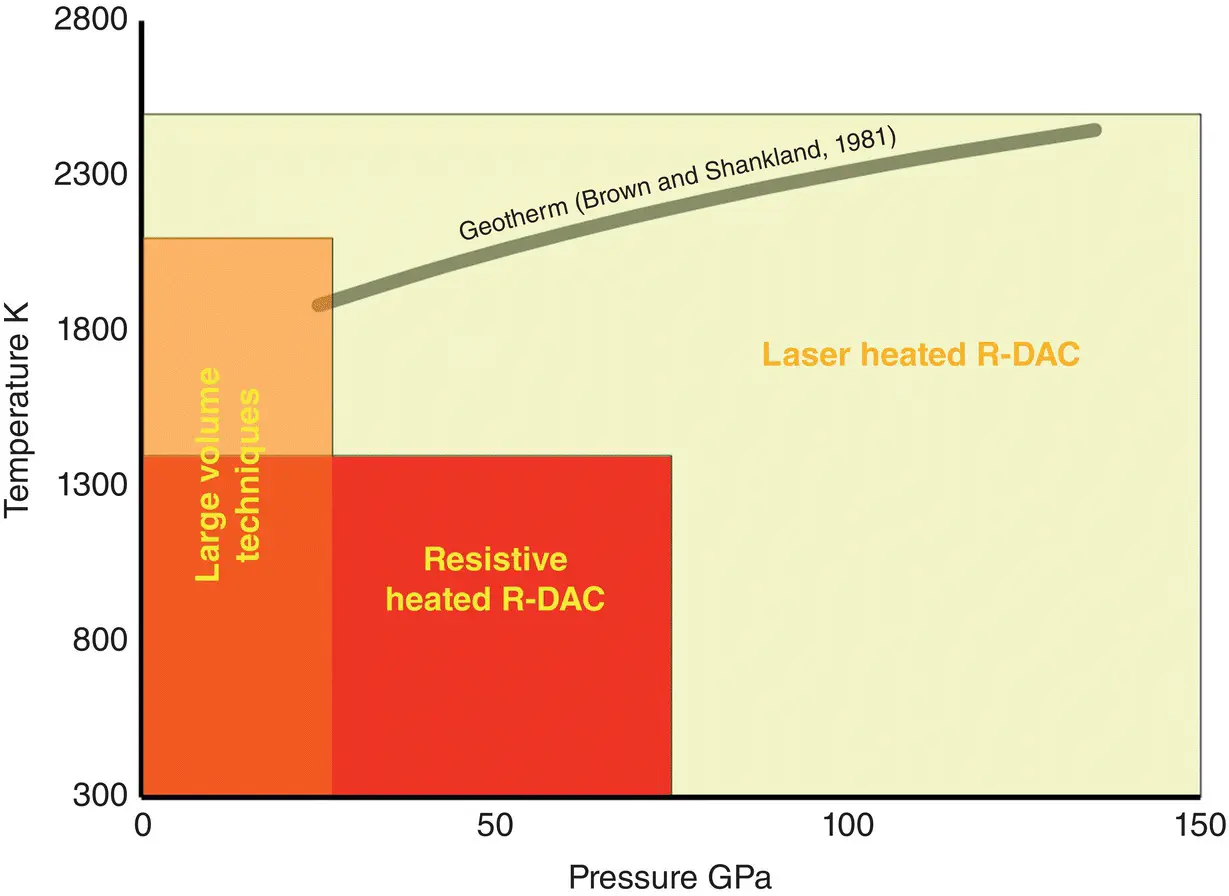

Although the DAC reaches the highest pressure range of all the deformation devices, it has many limitations. Generating high temperatures during DAC deformation is technically challenging; most DAC deformation experiments are room temperature. High temperatures are generated in the DAC through the use of electrical resistive heating or by focusing an infrared laser beam through the diamonds and onto the sample. Resistive heating produces relatively uniform temperatures within the sample, but temperatures are significantly lower than those that can be achieved through laser heating ( Figure 2.1). For radial diffraction resistive heating is also complicated by the fact that any heater surrounding the sample must allow passage of x‐rays in the radial direction. A graphite resistive heater has been developed for radial geometry (Liermann et al., 2009; Petitgirard et al., 2009) and has been used statically (without active compression) to generate temperatures as high as 1785 K at 40 GPa (Miyagi et al., 2013). More recently, Immoor et al. (2018) used this technique to deform a sample of Fp along a 1400 K isotherm to ~ 70 GPa ( Figure 2.1).

Laser heating can reach temperatures as high as ~ 6000 K (Boehler, 2000) but generally has large axial and radial temperature gradients (Boehler, 2000; Manga & Jeanloz, 1996). Axial gradients can result due to the high thermal conductivity of the diamond anvils, creating lower temperatures near the diamonds. Radial temperature gradients are more problematic for radial diffraction and arise because the laser hotspot is typically smaller than the sample dimensions. Gasket material may also conduct heat away from the edges of the sample. Additionally, temperatures may not be uniform throughout the laser hotspot. Advances such as double‐sided heating (Shen et al., 2001) and beam shaping (Prakapenka et al., 2008) have significantly reduced temperature gradients in the DAC. Surrounding the sample in an insulating material serves to both increase heating efficiency and reduce thermal gradients by reducing heat conduction away from the hotspot. However, for deformation experiments in radial geometry, this can be problematic. In addition to extra diffraction peaks from the insulating material, which complicates lattice strain and texture analysis, the insulation material must also be strong enough to impose deformation on the sample. If the insulation material is weak, strain will partition into the insulation material and the harder phase will remain relatively undeformed. As most lower mantle phases have high strength, this significantly limits the choice of insulation material, and in practice most radial diffraction measurements with laser heating do not use an insulating material. Additionally, laser heating in radial geometry is challenging, as most synchrotron beamlines are set up for laser heating in axial geometry, and reconfiguring the laser system for heating in radial geometry is difficult and time consuming (Kunz et al., 2007). Thus, only a few studies have performed radial diffraction experiments coupled with laser heating (Kunz et al., 2007; Merkel et al., 2004; Miyagi et al., 2013; Miyagi, Kunz, et al., 2008; Wu et al., 2017). The highest pressures and temperatures reached for radial diffraction and laser heating in the DAC are ~2500K and 150 GPa ( Figure 2.1; Wu et al., 2017).

Figure 2.1 Approximate pressure and temperature capabilities of various deformation devices including both large volume techniques and the radial diffraction diamond anvil cell (R‐DAC). Also plotted for reference is a “cold” mantle geotherm (Brown and Shankland, 1981).

In compression, experiments, diamonds induce both pressure and deviatoric stress on the sample, and these cannot be easily decoupled. Thus, studying deformation properties at a fixed confining pressure in the DAC is currently not possible. This means that flow stresses estimated from DAC experiments convolute strengthening due to pressure and strain hardening. Controlling strain rates is difficult in the DAC. Often, deformation is controlled through manual increase of pressure/stress through turning load screws. Not only does this result in a discontinuous increase in stress and strain, but it is incompatible with simultaneous heating and deformation. Furthermore, the small sample size makes it difficult to measure sample dimensions during experiments, and commonly strain (and thus strain rate) cannot be measured. The use of a gas membrane has somewhat improved on this, as compression is smoother than with screws. The DAC can also be used with a piezoelectric actuator, which can provide a more controlled compression than a membrane‐driven DAC (Evans et al., 2007; Jenei et al., 2019). The dynamic DAC has recently been combined with high‐resolution radiography to successfully measure small strains in an iron sample at high pressure (Hunt et al., 2018). Estimated total strains for compression in the DAC are ~0.3 (30%) and strain rates (albeit discontinuous) are on the order of 10 −4s −1(Marquardt & Miyagi, 2015). Recently, rotational DACs have been developed that allow large shear strains to be imposed at pressures in excess of 100 GPa (Azuma et al., 2018; Nomura et al., 2017).

Small sample sizes in the DAC further limit its capabilities as a deformation device. Sample sizes are quite small in the DAC, generally 0.03–0.05 mm thick at the start of an experiment and on the order of a few hundredths of a millimeter to a few tenths of a millimeter in diameter. This yields corresponding sample volumes of ~10 −2mm 3to 10 −5mm 3, but volumes become significantly reduced at high pressures. As a sufficient number of grains must be sampled to obtain statistically representative information, the upper limit of grain sizes feasible in the DAC is quite low. This makes studying the effect of changing grain size on rheology problematic in the DAC. One techniques that has been recently developed that somewhat alleviates this problem is the use of multigrain crystallography, which allows the use of coarse‐grained samples (Nisr et al., 2012). In spite of its many limitations, the DAC remains the only deformation device that can reach pressures covering the entire range of the lower mantle ( Figure 2.1).

2.3.2 Large‐Volume Deformation Devices

These devices cover a more limited pressure and temperature range than the DAC ( Figure 2.1) but have the advantage of allowing larger volume samples (on the order of a few mm 3), longer and more stable heating (via resistive heating), measurement of strain and strain rate, greater variation of grain size, and better control of the stress state (Karato & Weidner, 2008). The D−DIA is a six‐ram cubic type multianvil press. In this configuration, the top and bottom rams are differential, meaning that they can be moved independently of the other four rams (Y. Wang et al., 2003). This allows the user to advance all six rams simultaneously to increase pressure quasi‐hydrostatically. Additionally, by cycling the differential rams, the user can impose differential stress to shorten or lengthen the sample at a near fixed confining pressure. This allows better control of stress state and to some degree allows the user to decouple hydrostatic and deviatoric stresses. The D‐DIA generally operates up to ~10 GPa at 1600 K, but recent efforts using a D‐DIA with a multianvil 6‐6 assembly (a second stage of six anvils in a cubic geometry) has reached conditions as high as 20 GPa and 2000 K (Kawazoe et al., 2010). Tsujino et al. (2016) used a cubic press with a 6‐8 (a second stage of 8 anvils in octahedral geometry) assembly to deform a Brg sample to 25 GPa and 1873 K, by using pistons cut at 45° to induce shear strain. Another approach using the multianvil type apparatus that has proven successful is a 6–8 Kawai type multianvil assembly that has been modified with a pair of differential rams and is called the differential T‐CUP or DT‐CUP (Hunt et al., 2014). The 6‐8 multianvil design compresses an octahedral sample assembly and due to better support of the anvils can reach significantly higher pressures than a cubic (DIA) type press. Using a so‐called broken anvil design, the DT‐CUP has been used to successfully perform deformation experiments to 24 GPa and ~1800 K (Hunt & Dobson, 2017).

Читать дальше