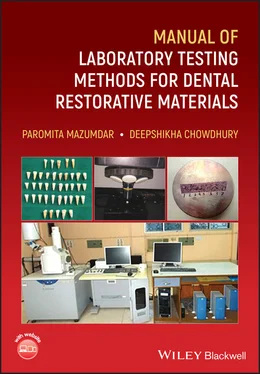

1 Cover

2 Title Page

3 Copyright Page

4 Preface

5 Acknowledgement

6 Glossary of Key Terms

7 About the Companion Website

8 Introduction

9 1 Assessment of Mechanical Properties of Dental Restorative Materials 1.1 Tensile Strength 1.2 Diametral Compression Test 1.3 Compressive Strength 1.4 Flexural Strength 1.5 Resistance to Fatigue 1.6 Hardness 1.7 Elastic Modulus 1.8 Fracture Toughness 1.9 Nanoindentation 1.10 Bond Strength References

10 2 Assessment of Physical Properties of Dental Restorative Materials 2.1 Assessment of Surface Roughness 2.2 Water Sorption and Solubility 2.3 Viscosity 2.4 Surface Tension 2.5 Degree of Conversion 2.6 Microleakage 2.7 Interfacial Adaptation and Film Thickness 2.8 Radiopacity References

11 3 Isolation and Identification of Oral Microflora 3.1 Isolation and Identification 3.2 Steps for Conducting an Experiment for Microbial Isolation and Identification 3.3 Molecular Biological Methods for Microflora Identification References

12 4 Assessment of Biocompatibility of Dental Materials 4.1 Standards for Testing Biocompatibility 4.2 Testing Hierarchy 4.3 Initial Tests for Assessment of Biocompatibility 4.4 Animal Tests 4.5 Usage Tests References

13 5 Assessment of Optical Properties 5.1 Perception of Color 5.2 Three Dimensions of Color 5.3 Color Measurements 5.4 Experimental Design for the Assessment of Color Stability 5.5 Test for Color Stability of Composite Resin (Pictorial Representation) 5.6 Assessment of Fluorescence 5.7 Assessment of Gloss References

14 6 Simulation of Oral Environment 6.4 Cyclic Loading Apparatus References

15 7 Extra Mile 7.1 Difference Between Dental Plaque and Biofilm 7.2 Virulence Factors of Biofilms 7.3 Biofilm Formation 7.4 Microorganisms in Oral Biofilms 7.5 In vitro Biofilm Models 7.6 Applications of In vitro Biofilm Models 7.7 Factors Affecting Biofilm Adhesion to Restorative Materials 7.8 Sample Preparation for Biofilm Study on Restorative Materials 7.9 Use of Biofilm Assays 7.10 Biofilm Formation on Restorative Materials References

16 Index

17 End User License Agreement

1 Introduction Table 1 ISO specifications to guide dental tests.

2 Chapter 3Table 3.1 Guidelines for storage of each specimen [8].Table 3.2 Magnification range of different microscopes.Table 3.3 The different variants of the PCR [20–22].

3 Chapter 4Table 4.1 Suitable extraction ratios for test materials of various thicknesses....Table 4.2 ANSI/ADA 41 biocompatibility tests for dental materials.Table 4.3 ISO 10993 biocompatibility tests for dental materials.Table 4.4 In vitro tests for commonly used dental materials.Table 4.5 The advantages and disadvantages of in vitro, animal tests, and usage...

1 Chapter 1 Figure 1.1 Universal testing machine. Figure 1.2 Tooth sample testing. Figure 1.3 Tensile strength assessment. Figure 1.4 Tensile strength assessment. Figure 1.5 1, No load; 2, uniform elongation; 3, maximum load; 4, necking. Figure 1.6 Diametral compressive strength assessment. Figure 1.7 Direction of force is perpendicular to the object. Figure 1.8 Schematic representation of the set‐up for compressive strength.... Figure 1.9 Schematic representation of flexural strength assessment. Figure 1.10 (a) Tooth sample, (b) crack propagation. Figure 1.11 Assessment of resistance to fatigue by cyclic compression stress... Figure 1.12 Vickers hardness testing. Figure 1.13 Knoop hardness testing. Figure 1.14 Vickers hardness tester. Figure 1.15 Brinell hardness testing. Figure 1.16 Rockwell hardness testing. Figure 1.17 Stress–strain curve for assessment of Young's modulus.

2 Chapter 2 Figure 2.1 Contact type surface roughness measurement device. Source: Thomas... Figure 2.2 Tip of the stylus. Source: Thomas [4] and Anonymous [5, 6].Figure 2.3 Taper sectioning method – Greater the taper, greater the height v...Figure 2.4 Reflected image appears in a straight line on a smooth surface.Figure 2.5 Specular reflection method. Source: Bennett and Porteus [10] and ...Figure 2.6 Diffuse reflection method.Figure 2.7 Schematic diagram of a digital profilometer.Figure 2.8 Schematic diagram of scanning tunneling microscope‐Px, Py.Figure 2.9 Schematic diagram of atomic force microscope. Source: Binnig and ...Figure 2.10 Schematic diagram of a U tube viscometer. Source: Based on Dauvi...Figure 2.11 Schematic diagram of a falling sphere viscometer.Figure 2.12 Goniometer.Figure 2.13 Diagrammatic representation of contact angle of a liquid on a su...

3 Chapter 3Figure 3.1 Spin vortex.Figure 3.2 Ultrasonic disperser.Figure 3.3 Incubator.Figure 3.4 Spread method.Figure 3.5 Hanging drop method.Figure 3.6 Spiral plate method.Figure 3.7 Manual colony counting.Figure 3.8 Conventional PCR machine.Figure 3.9 Agarose gel electrophoresis.Figure 3.10 Diagrammatic representation of DNA hybridization.Figure 3.11 Diagrammatic representation of Fluorescence in situ hybridizatio...Figure 3.12 Diagrammatic representation of T‐RFLP.Figure 3.13 Diagrammatic representation of DNA microarray.

4 Chapter 4Figure 4.1 Linear progression of testing hierarchy.Figure 4.2 Nonlinear progression of testing hierarchy.Figure 4.3 Biocompatibility testing based on risk assessment (US‐FDA 2016)....Figure 4.4 MTT assay.Figure 4.5 XTT assay.Figure 4.6 WST 1 assay.Figure 4.7 WST 8 assay.Figure 4.8 Lactate dehydrogenase assay.Figure 4.9 SRB assay.Figure 4.10 Neutral red uptake assay.Figure 4.11 Fluorometric assay.Figure 4.12 alamarBlue assay.Figure 4.13 Protease viability marker assay.Figure 4.14 Luminometric microplate reader.Figure 4.15 ATP assay.Figure 4.16 Barrier screen test.Figure 4.17 Agar diffusion test.Figure 4.18 Ame’s test.Figure 4.19 Patch test.Figure 4.20 Prick test.

5 Chapter 5Figure 5.1 Munsell color system.Figure 5.2 Vita classical shade guide.Figure 5.3 Vita 3D master shade guide.Figure 5.4 CIE lab system.Figure 5.5 Composite resin specimen.Figure 5.6 ShadeEye colorimeter.Figure 5.7 Vita easy shade spectrophotometer.Figure 5.8 Digital image analysis set up for laboratory assessment of color ...Figure 5.9 X Rite colorimeter incorporated with digital imaging system.Figure 5.10 Placement of composite resin in mold.Figure 5.11 Placement of glass slab over the uncured specimen.Figure 5.12 Curing of the sample using LED light curing unit.Figure 5.13 Composite resin specimen.Figure 5.14 Storage of specimens in distilled water.Figure 5.15 Immersion in beverages.Figure 5.16 Digital image analysis setup.

6 Chapter 6Figure 6.1 Commercially available artificial saliva.Figure 6.2 Water bath thermocycling.Figure 6.3 Flexiforce sensor A401.Figure 6.4 Diagrammatic representation of the cyclic loading apparatus.Figure 6.5 Experimental set‐up for pH cycling.Figure 6.6 Customized automated tooth brushing machine.Figure 6.7 Tooth embedded in alginate to simulate periodontium during in vit...

1 Introduction

2 Cover Page

3 Title Page

4 Copyright Page

5 Preface

6 Acknowledgement

7 Glossary of Key Terms

8 About the Companion Website

9 Table of Contents

10 Begin Reading

11 Index

12 Wiley End User License Agreement

1 iii

2 iv

3 ix

4 x

5 xi

6 xiii

7 xiv

8 xv

9 1

10 2

11 3

12 4

13 5

14 6

15 7

16 8

17 9

18 10

19 11

20 12

21 13

22 14

23 15

24 16

25 17

26 18

27 19

28 20

29 21

30 22

31 23

32 24

33 25

34 26

35 27

36 28

37 29

38 30

39 31

40 32

41 33

Читать дальше