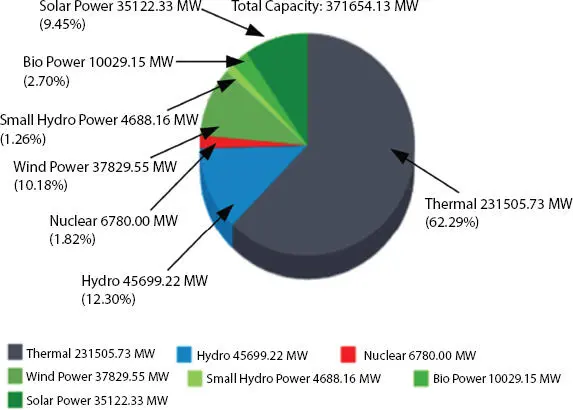

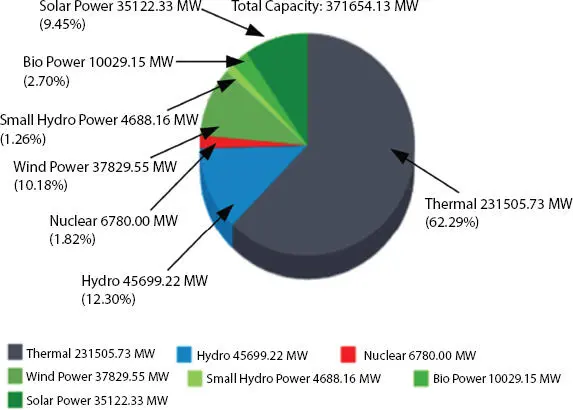

India, a rapidly growing economy in the world, is now the third largest producer of electric power with the production of 1,643 TWh of electric energy in the year 2019. It deploys diverse ways of generating electrical energy. Although Indian power sector is dominated by fossil fuels, the Government of India with a view of sustainable development set an ambitious target of renewable installed capacity of 175 GW by FY22. The total installed capacity as of 21 July 2020 is 371,654.13 MW. The thermal generation accounts for 62.29% as shown in Figure 2.1[1, 2]. After thermal generation, hydropower generation stands second in the list. Wind power and solar power generation are two main renewable energy sources exploited in India [3].

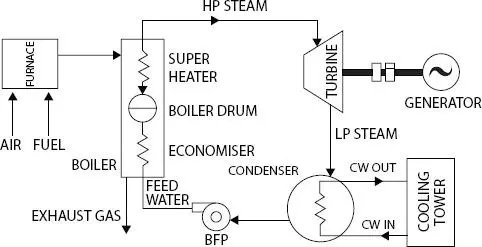

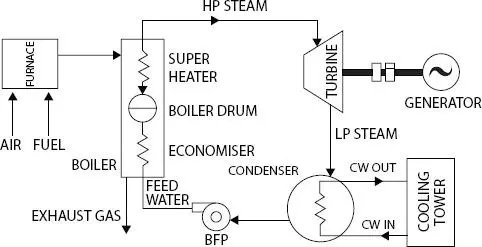

In India, thermal energy is the major source of power generation. The thermal power plant produces more than 60% of the electrical power in India. India is the fifth largest producer of coal in the world [3]. Generally, bituminous coal is used as a boiler fuel in India. Figure 2.2shows the schematic diagram of a typical thermal power plant.

Figure 2.1 Installed capacity in India.

Figure 2.2 A typical thermal power plant.

The heat energy from the combustion of fossil fuels is utilized by the boilers to produce steam at high pressure and temperature. The steam produced is used to drive the steam turbines or steam engines coupled to generators, and thus, electrical energy is generated in the thermal power plant. Steam turbines act not only as prime movers but also as drivers for auxiliary equipment such as pumps and stokers fans [4].

The thermal power plant can be classified into two types:

1 (i) Condensing type: In this type, the exhaust steam is discharged into a condenser, which creates suction at very low pressure and allows the expansion of steam in the turbine to very low pressure and thus increases the efficiency. During this process, steam is condensed into the water which can be re-circulated to the boiler with the help of pumps.

2 (ii) Non-condensing type: In this type, the steam exhausted from the turbine is discharged either at atmospheric pressure or pressure greater than atmospheric. In this type of plant, a continuous supply of fresh feed water is required.

2.2.1 Components of Thermal Power Plant

1 (i) Boiler and Boiler Furnace: A boiler incorporates a furnace to burn the fossil fuel (coal, gas, waste, etc.) and generate heat/steam which is transferred to water to make steam. The types of boiler used in a thermal power plant are water tube and fire tube boiler.

2 (ii) Superheater: It is used to convert the wet steam or saturated steam in to dry steam or superheated steam. Superheated steam contains more heat than the saturated steam at the same pressure. The more heat provides more energy to the turbine hence power output is more.

3 (iii) Economizer: It is used to capture the waste heat from flue gas and transfer it to the boiler feedwater. Economizer alone can produce 10%–12% efficiency increase; thereby, it saves 5%–15% fuel consumption.

4 (iv) Condenser: It is used to convert the steam exhausted from the turbine into the water so that it can be reused again in the boiler. There are two types of condensers are used and they are jet and surface condensers.

5 (v) Feed Water Heaters: A feedwater heater is used in a conventional power plant to preheat boiler feedwater. The source of heat is steam bled from the turbines, and the objective is to improve the thermodynamic efficiency of the cycle.

6 (vi) Air Preheaters: After leaving the economizer, further heat from the flue gas is used to heat the incoming air using air preheater. Flue gas should not be cooled below the dew point to avoid corrosion of the air preheater.

7 (vii) Turbines: There are two types of turbines used:Impulse turbine: In this turbine, moving and fixed blades are used. The moving blades are mounted on the shaft and fixed blades are fixed to the casing of the turbine. Steam is passed through the fixed nozzles. The steam with high velocity comes out of the nozzle and impinges on the rotor blades.Reaction turbine: In this turbine, only fixed and moving blades are used. When high-pressure steam passes through fixed blades, then steam pressure drops down, and the velocity of steam increases.

8 (viii) Cooling towers: The cooling tower transfers the heat from the water’s heat to the air by directly or by evaporation of the water. So that water coming out of the condenser is reused.

Advantages of Thermal Power Plant

Fuel cost is comparatively low.

Installation requires less land compared to a hydropower plant.

The thermal energy production mechanism is simple and easy.

The initial cost is lesser compared to other power plants.

Easy maintenance.

Disadvantages

The huge production of CO2 which causes pollution.

Overall efficiency is less than 30%.

A huge amount of water is required.

Warm water comes out of the thermal power plant affects aquatic life.

Thermal engines require a huge amount of lubricating oil.

2.2.2 Major Thermal Power Plants in India

1 Sasan Ultra Mega Power Plant, Madhya Pradesh: It holds an installed capacity of 3,960 MW situated in Sasan Village of the Singrauli district. Reliance power owns this power plant integrated with a coal mine.

2 Tiroda Thermal Power Plant, Maharashtra: It holds an installed capacity of 3,300-MW plant which covers an area of 454.8 ha owned by Adani power. It uses water from the Wainganga River to go ahead with its operations.

3 Talcher Super Thermal Power Station, Odisha: It holds an installed capacity of 3,000 MW owned by NTPC situated in the Angul district of Odisha.

4 Vindhyachal Thermal Power Station, Madhya Pradesh: It holds an installed capacity of 4,760 MW owned by NTPC. Presently, this is the biggest thermal power plant in India.

5 Mundra Thermal Power Station, Gujarat: It holds an installed capacity of 4,620 MW owned by Adani power. Presently, this is the second biggest thermal power plant in India.

6 Mundra Ultra Mega Power Plant, Gujarat: This is another one situated in Kutch district holds an installed capacity of 4,000 MW owned by CGPL.

7 Rihand Thermal Power Station, Uttar Pradesh: It holds an installed capacity of 3,000 MW owned by NTPC. The plant generates and supplies electricity to different states in the northern part of India such as Uttarpradesh, Rajasthan, Delhi, Punjab, Haryana, and Himachal Pradesh.

8 Sipat Thermal Power Plant, Chhattisgarh: It holds an installed capacity of 2,980 MW owned by NTPC. This is the eighth largest thermal power plant in India.

9 Chandrapur Super Thermal Power Station, Maharashtra: It holds an installed capacity of 2,920 MW operated by Maharashtra state power generation company.

10 NTPC Dadri, Uttar Pradesh: It holds an installed capacity of 2,637 MW owned by NTPC. This is the sixth largest thermal power plant in India.

2.3 Gas-Based Power Generation

India’s power generation is contributed almost by all types of conventional and non-conventional power generating plants. But, it is always inclined toward the coal-based power generation. With the increasing new establishments and demands, it is stated that the natural availability of coal will be limited and the coal sector will face a shortfall in the upcoming future.

Читать дальше