1 ...7 8 9 11 12 13 ...16 To be effective, you need to involve the people in the process, equipping and empowering them to both feel able and be able to challenge and improve the way the work gets done. Involving people is what has to be done if organizations are to be truly effective, but, like so many of the Lean Six Sigma principles, it requires different thinking if it’s to happen. (See Chapter 6for more about the power of the people.) Continuous Improvement is a mindset — some call it a “growth mindset” — that embraces challenges and seeks opportunities to learn and understands that it’s worth putting in the effort to get the results. Leaders play an important role in creating this type of spirit in their organizations so that everyone can contribute.

Undertake improvement activity in a systematic way

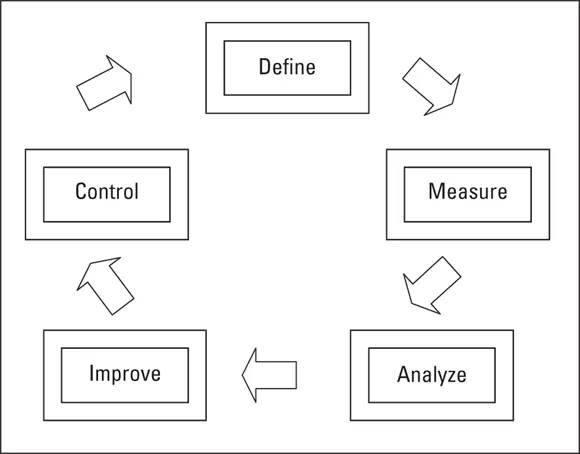

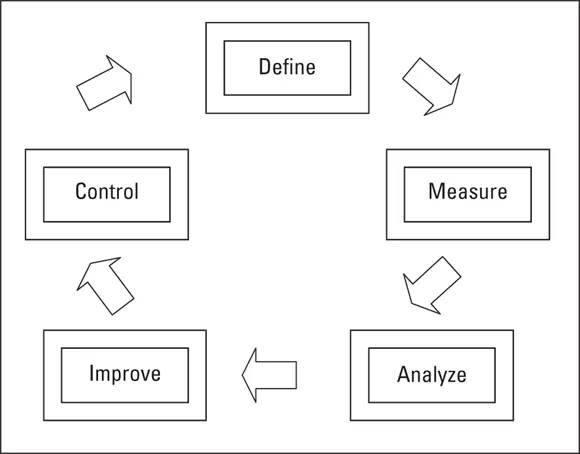

The systematic approach used is known as DMAIC: Define, Measure, Analyze, Improve and Control. One of the criticisms sometimes aimed at “stand-alone” Lean is that improvement action tends not to be taken in a systematic and standard way. In Six Sigma, DMAIC is used to improve existing processes, but the framework is equally applicable to Lean and, of course, Lean Six Sigma. Where a new process needs to be designed, the DMADV method is used. Chapters 14and 15describe DMADV and the Design Thinking approach.

Less is usually more. Tackle problems in bite-sized chunks and never jump to conclusions or solutions.

Less is usually more. Tackle problems in bite-sized chunks and never jump to conclusions or solutions.

The focus in the following section is on improving existing processes with DMAIC using the appropriate tools and techniques from the Lean Six Sigma toolkit. But these tools, and the seven principles identified earlier in this chapter, also provide a framework to improve the day-to-day management and operation of processes. We look at this aspect of Lean Six Sigma, which we refer to as “Everyday Operational Excellence,” in Chapter 18.

Improving Existing Processes: Introducing DMAIC

DMAIC (Define, Measure, Analyze, Improve, and Control) provides the framework to improve existing processes in a systematic way. DMAIC projects begin with the identification of a problem, and in the Define phase you describe what you think needs improving. Without data this might be based on your best guess of things, so in the Measure phase you use facts and data to understand how your processes work and perform so that you can pinpoint the problem more effectively.

Now you can Analyze the situation by using facts and data to determine the root cause(s) of the problem that’s inhibiting your performance. With the root cause identified, you can now move to the Improve phase, identifying potential solutions, selecting the most suitable, and testing or piloting to validate your approach, using data where appropriate. You’re then ready to implement and monitor the solution in the Control phase.

The Control phase is especially important. You need to implement your solution, checking that your customers feel the difference in performance. You’ll need to use data to determine the extent of the improvement and to help you hold the gains. After all that work, you don’t want the problem you’ve solved to recur. With the right ongoing measures in place, you should also be able to prompt new opportunities.

The following sections provide a little more detail about the five DMAIC phases. Figure 2-1 shows how the phases link together, though the process is not necessarily linear. It could be that in the Define phase, for example, the problem that you are planning to tackle can’t be adequately quantified. In the Measure phase, you’ll be collecting data that enables you to go back to Define and update your description of the problem.

© Martin Brenig-Jones and Jo Dowdall

FIGURE 2-1:The five phases of DMAIC.

When you start an improvement project, ensuring that you and your team understand why you’re undertaking the project and what you want to achieve is an essential ingredient for success. With a DMAIC project, you start with a problem that needs to be solved. Before you can solve the problem, you need to define it. One of the key outputs from the Define phase is a completed improvement charter .

The improvement charter is an agreed document defining the purpose and goals for an improvement team. It can help address some of the elements that typically go wrong in projects by providing a helpful framework to gain commitment and understanding from the team. Keep your charter simple and try to contain the document to one or two sides of A4 in line with the example shown in Figure 2-2.

The improvement charter contains the following key elements:

A high-level business case providing an explanation of why undertaking the project is important.

A problem statement defining the issue to be resolved.

A goal statement describing the objective of the project.© Martin Brenig-Jones and Jo Dowdall FIGURE 2-2:A sample improvement charter.

The project scope defining the parameters and identifying any constraints.

The CTQs specifying the problem from the customer’s perspective. Unless you already have the CTQs, these may not be known until the Measure phase.

Roles identifying the people involved in and around the project, expectations of them and their responsibilities. The improvement charter forms a contract between the members of the improvement team, and the champion or sponsor.

Milestones summarizing the key steps and provisional dates for achieving the goal.

The improvement charter needs to be seen as a “living document” and be updated throughout the various DMAIC phases, especially as your understanding of the problem you’re tackling becomes clearer.

Creating the problem statement can be trickier than it sounds. A well done statement provides an effective starting point (“a problem well stated is a problem half solved” said John Dewey), but it should not include the cause of the problem, or the potential solution. Remember, the DMAIC framework will take us there, and at this stage, if you really do already know the cause of the problem and the solution to address it (with data to back you up), then you don’t need DMAIC. You just need to get on and do it!

Here's an example of a problem statement:

Sales of online products have dropped over the last three months, from $272k to $181k, and our forecast is down by 25%.

You’ll notice that some baseline information has been included to help underline the extent of the problem. This makes the problem statement more effective, as it’s far easier to communicate the problem and to start to influence stakeholders with a factual problem statement like this than it is to say something vague like, “I think sales are dropping.”

The 5Ws and 1H tool can help to add structure and detail to problem statements. This tool is brilliantly simple and extremely versatile. “5Ws and 1H” stands for What, Why, When, How, Where and Who — six questions that, when answered with facts, provide all the information needed to define the problem:

WHAT is the problem?

WHY is it beneficial to address this problem now?

WHEN does it happen / when did it start?

HOW does it show itself to be a problem? (For example, rework, customer complaints, feedback from a regulator.)

WHERE does it happen?

WHO is affected by it?

Читать дальше

Less is usually more. Tackle problems in bite-sized chunks and never jump to conclusions or solutions.

Less is usually more. Tackle problems in bite-sized chunks and never jump to conclusions or solutions.