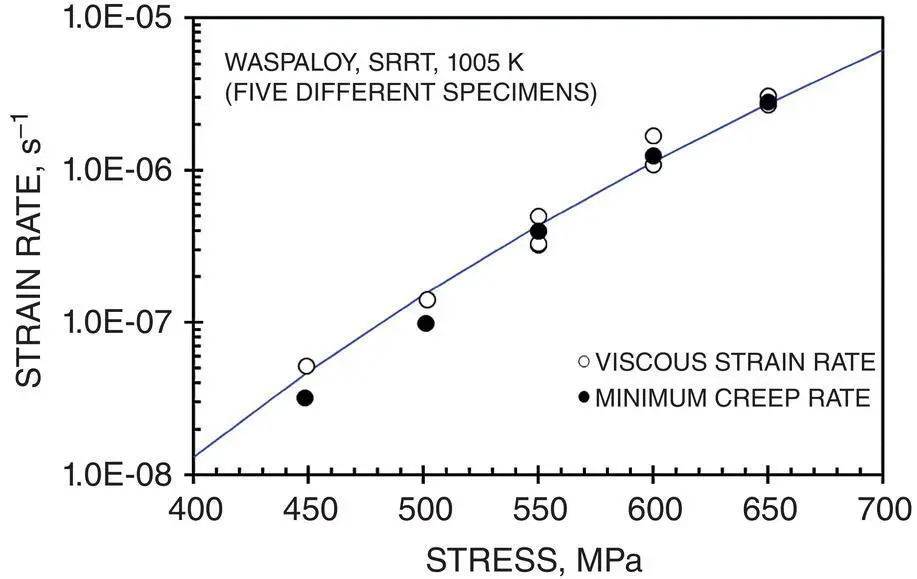

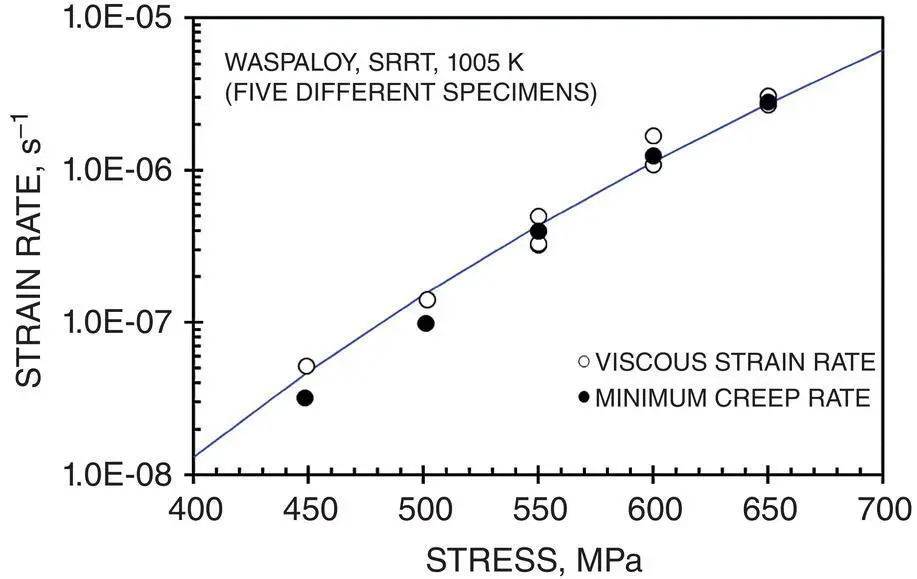

Figure 1.8 Stress dependence of average viscous strain rate during primary creep and the corresponding minimum creep rate from short‐term and long‐term SRRTs on five different specimens of Waspaloy at 1005 K.

Source: N. K. Sinha.

The numerical equivalency of n vand n min, for stress levels of engineering importance, has far‐reaching consequences. Since failure and fractures in metals and alloys at high temperatures are traditionally linked to n min, does it mean that SRRTs requiring “a single specimen” can be used for the characterization of failures? Sounds incredible! One of the primary goals for writing this book is to convince metallurgists, ceramicists, and rock mechanics researchers to use SRRTs and explore certain important aspects of materials (delayed elasticity and crack nucleation and multiplication during primary creep stages) neglected so far in the general field of materials science and engineering.

One approach of utilizing the methodology of “hindsight” is to perform a series of creep and recovery tests (SRRTs) on one specimen. For each test, the full load is applied as quickly as possible and, at the end of the creep time, completely unloaded from the specimen very quickly. The strain is continuously monitored during the recovery. This approach allows one to explore the “trinity of creep” in a quantitative manner at different stages of creep. It is by no means a novel approach, but improvements can be made by decreasing the durations of loading and unloading, and by increasing the observation time during recovery. The initial strain, ε i, on full loading provides an “effective” elastic modulus, E i, which can be compared with Young's modulus, E, obtained from seismic or resonance technique. The difference ΔE = E−E iprovides a measure of the weakness in the loading sequence and can be improved and optimized by decreasing ΔE. The residual strain after full recovery provides a measure of the “viscous” strain, ε v, and the “average viscous strain” rate,  (defined by Equation 1.1), for the load‐duration time, t (shown in Figure 1.5). This “pseudo” strain rate (

(defined by Equation 1.1), for the load‐duration time, t (shown in Figure 1.5). This “pseudo” strain rate (  ) can be numerically compared with the “secondary” creep rate.

) can be numerically compared with the “secondary” creep rate.

An example of the above approach is illustrated in Figure 1.5. It shows that the “pseudo” or the average strain rate (  ) during the first 200 s during the primary creep of the short test is 3.05 × 10 −6s −1. It may be safely assumed that “negligible” structural damage occurred in the specimen during this test. Now compare this

) during the first 200 s during the primary creep of the short test is 3.05 × 10 −6s −1. It may be safely assumed that “negligible” structural damage occurred in the specimen during this test. Now compare this  with the slightly lower

with the slightly lower  of 2.68 × 10 −6s −1for the entire 2342 s of the long test performed on the same specimen. The difference is small, but may be linked to the expected structurally damaged state of the specimen undergoing tertiary creep. These two estimations are subjected to least experimental errors in comparison with the estimation of the minimum creep rate (mcr), as all experimentalists can understand. The mcr was estimated to be 2.8 × 10 −6s −1that occurred at about 800 s as shown in Figure 1.5. No importance can be given to the fact that this value lies in between the other two values, but why is this numerically comparable to the average viscous strain rate during the primary creep? This similarity opens a floodgate of experimental possibilities and potentials of SRRT (presented in Chapters 4– 9) and theoretical nightmares for materials scientists, in general, concentrating on numerous hypothesis on the generations, multiplications, annihilations, climb, etc. and hence interactions of matrix dislocations with grain boundaries during primary creep leading to steady‐state creep rate.

of 2.68 × 10 −6s −1for the entire 2342 s of the long test performed on the same specimen. The difference is small, but may be linked to the expected structurally damaged state of the specimen undergoing tertiary creep. These two estimations are subjected to least experimental errors in comparison with the estimation of the minimum creep rate (mcr), as all experimentalists can understand. The mcr was estimated to be 2.8 × 10 −6s −1that occurred at about 800 s as shown in Figure 1.5. No importance can be given to the fact that this value lies in between the other two values, but why is this numerically comparable to the average viscous strain rate during the primary creep? This similarity opens a floodgate of experimental possibilities and potentials of SRRT (presented in Chapters 4– 9) and theoretical nightmares for materials scientists, in general, concentrating on numerous hypothesis on the generations, multiplications, annihilations, climb, etc. and hence interactions of matrix dislocations with grain boundaries during primary creep leading to steady‐state creep rate.

Most fundamental studies have concentrated exclusively on “steady‐state” behavior and ignored the primary or the transient creep – which are of high importance for the engineering design of various components. These fundamental studies shaped the materials world, including the rock mechanics people, even though it is well known that earthquakes are linked to transient creep, which are known to depend on materials characteristics, temperatures, strain/stress rate, etc. As a consequence, most experimental investigations, undertaken to understand dependence of creep and failure on materials variables, reported only the characteristics of the mcr.

The approach of opening the door for the “hindsight” described above was taken by the senior author while investigating high‐temperature rheo‐optical behavior of glass in connection with the thermal tempering of structural glass (Sinha 1971). On application of external forces, shearing between ordered (crystal‐like) and disordered zones may develop internal strain (stress) concentrations in silicate glasses with no long‐range orders in the matrices (see Section 2.4.2, “Structure of Real Glass”). These stress concentrations, in absence of any relaxation processes, could become the driving forces on unloading and generate delayed elastic effects in glass. The question is, what happens when the size of the “ordered zones” increases drastically at the cost of “disordered zones”? Do we end up with polycrystalline (ordered) materials with thin layers of grain boundaries (disordered)? Shearing between grain‐boundaries during loading could therefore develop stress concentrations (elastic distortion of the lattice) at triple boundaries because of intragranular lattice distortions near triple‐grain boundaries. The approach used for examining delayed elastic effects in glass was then successfully applied to directionally solidified columnar‐grained pure S‐2 ice (Sinha 1978b) using a conventional dead‐load lever system. However, state‐of‐the‐art, computer‐controlled, servo‐hydraulic technology has provided us with the opportunity to load fully and unload completely in fractions of second for a wide range of stress. Moreover, improvements in measuring specimen strain at high temperatures and controlling it by closed‐loop systems (such as truly constant rate) provide a measure of deformation that was not possible in the past (details are provided in Chapter 4). This is the main reason why the above‐described creep and recovery methodology required a new name – SRRT.

To better understand the need for a new name, let us divert our attention a bit to stress relaxation. Engineering components of nuts and bolts face serious problems at high temperatures, because the bolts lose their grip with time. To understand this issue, Stress Relaxation Tests (SRTs) are performed. An SRT is performed by suddenly applying a strain (constraint) and monitoring the decrease in stress with time. SRT is a universally accepted name. To be consistent, why not use “strain relaxation test” (also SRT) for the test in which a stress is suddenly applied and the increase in strain is monitored thereafter? But that term may create confusion. A clear distinction can be made, however, by adding the “hindsight” or the “recovery” aspect of the new test method to the name. Hence, the name SRRT was chosen for the test approach described above.

Читать дальше

(defined by Equation 1.1), for the load‐duration time, t (shown in Figure 1.5). This “pseudo” strain rate (

(defined by Equation 1.1), for the load‐duration time, t (shown in Figure 1.5). This “pseudo” strain rate (  ) can be numerically compared with the “secondary” creep rate.

) can be numerically compared with the “secondary” creep rate. ) during the first 200 s during the primary creep of the short test is 3.05 × 10 −6s −1. It may be safely assumed that “negligible” structural damage occurred in the specimen during this test. Now compare this

) during the first 200 s during the primary creep of the short test is 3.05 × 10 −6s −1. It may be safely assumed that “negligible” structural damage occurred in the specimen during this test. Now compare this  with the slightly lower

with the slightly lower  of 2.68 × 10 −6s −1for the entire 2342 s of the long test performed on the same specimen. The difference is small, but may be linked to the expected structurally damaged state of the specimen undergoing tertiary creep. These two estimations are subjected to least experimental errors in comparison with the estimation of the minimum creep rate (mcr), as all experimentalists can understand. The mcr was estimated to be 2.8 × 10 −6s −1that occurred at about 800 s as shown in Figure 1.5. No importance can be given to the fact that this value lies in between the other two values, but why is this numerically comparable to the average viscous strain rate during the primary creep? This similarity opens a floodgate of experimental possibilities and potentials of SRRT (presented in Chapters 4– 9) and theoretical nightmares for materials scientists, in general, concentrating on numerous hypothesis on the generations, multiplications, annihilations, climb, etc. and hence interactions of matrix dislocations with grain boundaries during primary creep leading to steady‐state creep rate.

of 2.68 × 10 −6s −1for the entire 2342 s of the long test performed on the same specimen. The difference is small, but may be linked to the expected structurally damaged state of the specimen undergoing tertiary creep. These two estimations are subjected to least experimental errors in comparison with the estimation of the minimum creep rate (mcr), as all experimentalists can understand. The mcr was estimated to be 2.8 × 10 −6s −1that occurred at about 800 s as shown in Figure 1.5. No importance can be given to the fact that this value lies in between the other two values, but why is this numerically comparable to the average viscous strain rate during the primary creep? This similarity opens a floodgate of experimental possibilities and potentials of SRRT (presented in Chapters 4– 9) and theoretical nightmares for materials scientists, in general, concentrating on numerous hypothesis on the generations, multiplications, annihilations, climb, etc. and hence interactions of matrix dislocations with grain boundaries during primary creep leading to steady‐state creep rate.