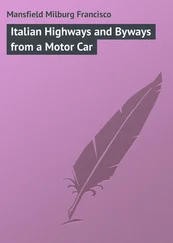

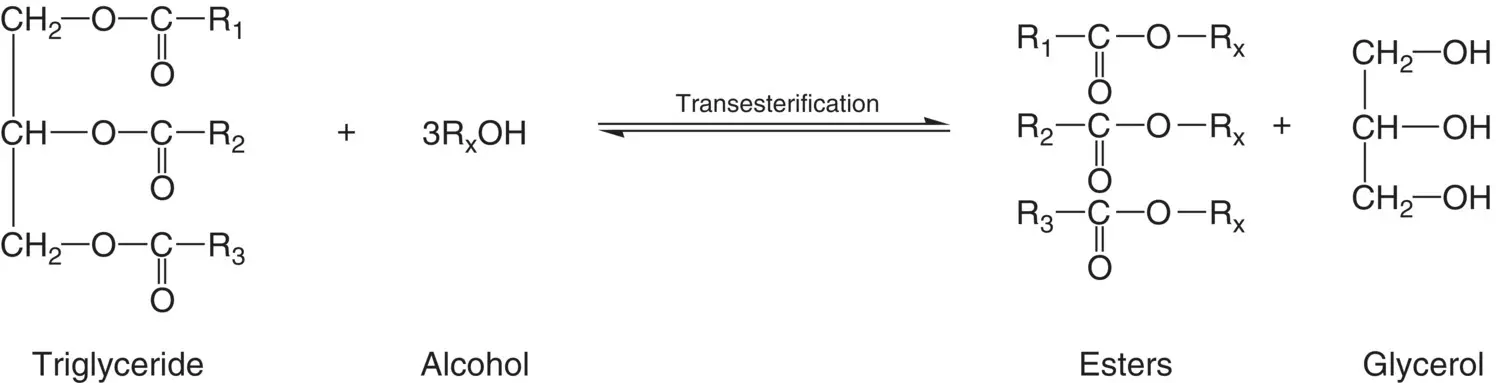

Figure 2.5 Transesterification of triglyceride.

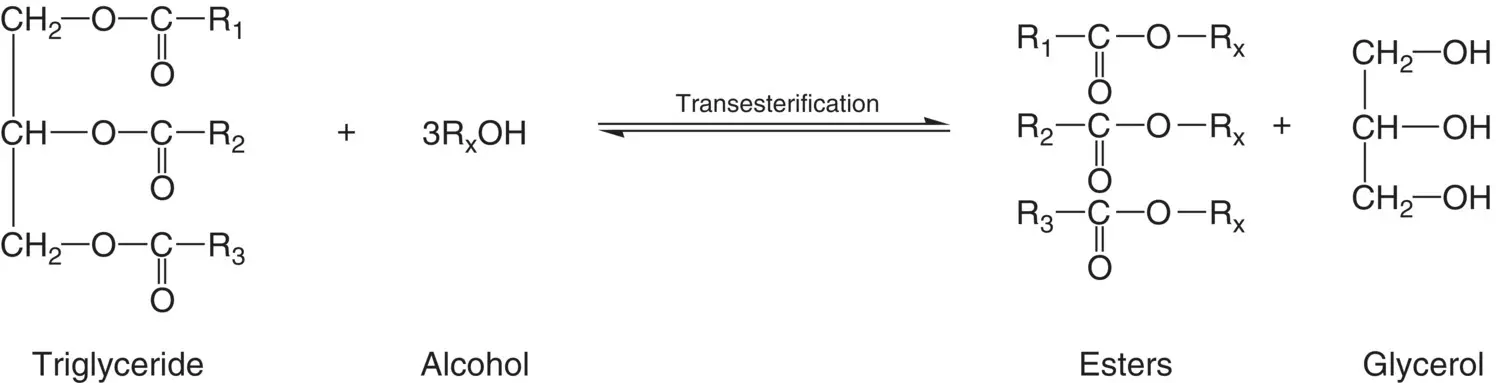

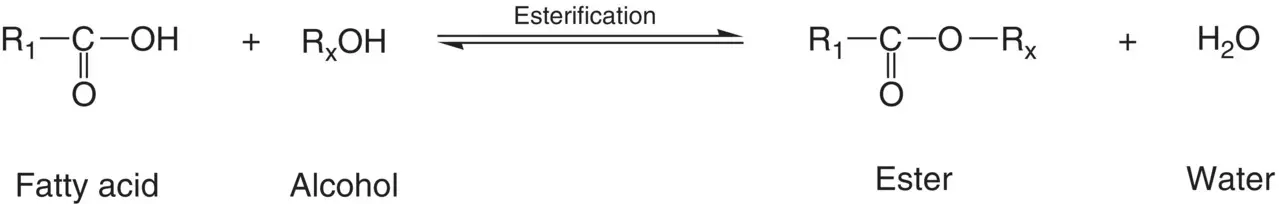

For feedstocks containing high free fatty acid content, the use of an acid solid catalyst is an alternative to produce biodiesel via esterification reaction ( Figure 2.6) [103]. Several solid acids such as metal oxides (particularly ZrO 2, TiO 2, and SnO 2), sulfonic acid‐modified materials, and heteropolyacids have been used in esterification [104–106]. Considering the economic aspect of the biodiesel production process, the price of raw materials and the catalyst are two major determinants of the overall biodiesel production cost [107]. Therefore, much attention has been paid to the utilization of low‐cost bio‐based carbonaceous solids in biodiesel production because of their inexpensive carbon sources, convenient preparation, and easily tunable physical and chemical properties [108]. Furthermore, covalent attachment of active groups such as SO 3H, COOH, and phenolic OH groups on the surface of biochar improve the biochar characteristics. Of the various functionalized catalysts, the sulfonated carbon‐based catalyst is among the most competent for biodiesel production [109]. Effects of the different forms of sulfonating precursors modified on raw biochar support were investigated. Biochar sulfonated with fuming sulfuric acid had a superior acid density over that sulfonated with concentrated sulfuric acid, resulting in a higher activity in the transesterification of vegetable oil. Further modification of biochar with KOH before sulfonating with fuming sulfuric acid could maximize the catalytic activity for transesterification as KOH ascribed to an enhanced porosity, surface area, and acid density of the catalyst [6]. Carbonization of biomass followed by sulfonation resulted in catalysts containing SO 3H, COOH, and OH groups, in which the number of SO 3H groups significantly influence the catalytic activity for biodiesel production [110]. Leaching of SO 3H groups caused the deactivation of the catalyst. The efficiency of esterification between oleic acid and ethanol calculated from the reduction of the reactant acidity reached 98.40% when the time to introduce the SO 3H groups into the bamboo‐derived catalyst was increased from 60 to 120 minutes [111]. Thus, not only the type of sulfonating precursor but also the sulfonating conditions affect the catalytic efficiency.

More information on biodiesel yield produced in the presence of various heterogeneous catalysts is summarized in Table 2.4. In comparison to non‐biomass‐derived catalysts mentioned in this discussion, not only the catalysts produced from carbon‐rich biomass but also from calcium carbonate‐rich biomass have the potential to be competitive with commercial alkali and metal oxide catalysts in biodiesel production. Even though biomass‐derived catalysts showed a slightly lower biodiesel yield, paying more attention to research in biodiesel production with bio‐based catalysts will shortly achieve better results in terms of product yield, catalyst stability, environmental friendliness and cost‐efficiency.

2.5.3 Biomass‐Derived Activated Carbon

Biomass‐derived activated carbons are conventionally produced from diverse renewable sources via carbonization and activation. The sequence of processes in activated carbon production from biomass causes a considerable increase in the porosity and specific surface area. Other unique properties of activated carbon comprise thermal resistance, stability in both acidic and basic environment, and the possibility to tailor both its physical and surface chemical properties. To satisfy the requirements for catalyzing a specific reaction, activated carbons can be treated with KOH or CaO via wet impregnation. The stability of such immobilized catalysts, however, is relatively low. To improve the performance of activated carbon, chemical treatment with oxidizing acids such as SO 3H, H 3PO 4, or HNO 3is an interesting choice [119–121]. In view of the catalytic potential, sulfonated carbon catalysts are widely attractive in reactions such as hydrolysis, esterification, and transesterification. Sulfonated bio‐based carbon catalysts can be prepared by direct sulfonation or sulfonation via reductive alkylation/arylation reactions.

Figure 2.6 Esterification of fatty acid.

Table 2.4 Comparison of various catalysts for biodiesel production.

| Catalyst |

Feedstock |

Reaction conditions |

Yield (%) |

References |

| Alcohol:Oil |

Catalyst amount (wt%) |

Temperature (°C) |

Time |

| La 2O 3/CaO |

Jatropha oil |

25 : 1 |

3 |

160 |

3 h |

98.76 |

[112] |

| Li/CaO |

Jatropha oil |

12 : 1 |

5 |

65 |

1–2 h |

>99 |

[113] |

| ZnO‐TiO 2‐Nd 2O 3/ZrO 2 |

Soybean oil |

5.7 : 1 |

— |

195 |

44 min |

99 |

[104] |

/SnO 2 /SnO 2 |

Waste cooking oil |

15 : 1 |

3 |

150 |

3 h |

92.3 |

[105] |

| Bio‐based carbon modified with Ni and Na 2SiO 3 |

Soybean oil |

9 : 1 |

7 |

65 |

100 min |

98.1 |

[114] |

| Sulfonated modified coconut meal residual |

Waste palm oil |

12 : 1 |

5 |

65–70 |

10 h |

92.7 |

[115] |

| Sulfonated modified carbonized coconut shell |

Palm oil |

30 : 1 |

6 |

60 |

6 h |

88.25 |

[116] |

| Sulfonated woody biochar |

Canola oil |

30 : 1 |

7 |

315 |

3 h |

48.1 |

[117] |

| Sulfonated carbonized bamboo |

Oleic acid |

7 : 1 |

6 |

90 |

2 h |

98.4 |

[111] |

| Calcium oxide from eggshell |

Waste cooking oil |

6 : 1 |

5.8 |

Room temperature |

11 h |

97 |

[118] |

Sulfonated activated carbons from various biomass resources were tested for the production of biodiesel through esterification or transesterification. Various kinds of biomass wastes were activated with H 3PO 4prior to carbonization and subsequently sulfonated through arylation of 4‐benzenediazonium. The resulting bio‐based activated carbon materials were highly porous with surface areas of 640–970 m 2g −1depending on the biowaste source. Under optimal conditions, conversion of up to 94% could be achieved for esterification [120]. Slow reaction rates, the requirements of high methanol‐to‐oil molar ratios, and high reaction temperatures are, however, weaknesses of the sulfonated carbon catalyst for biodiesel production [122]. A further application with regard to the upgrading of bio‐oil via reactive distillation including water removal, catalytic esterification, and neutralization steps was carried out with p‐toluene sulfonic acid embedded on an activated carbon obtained by activation of sawdust pellets [123]. The catalyst was applied to the catalytic esterification in the reactive distillation procedure. After water removal from the oil, the esterification reaction took place at 80 °C under atmospheric pressure with the acid‐modified activated carbon catalyst and zeolite. The heating value of the upgraded bio‐oil obtained from fast pyrolysis was improved from 14.80 to 23.13 MJ kg −1and was ascribed to the presence of higher ester and acetic acid contents in the oil according to the reaction in Figure 2.7. The properties of the upgraded oil were consistent with the diesel standard. Interestingly, sulfonated activated carbon catalysts have the potential for bio‐jet fuel production through co‐pyrolysis of biomass and plastic waste [124]. Prior to the sulfonation step, an activated corncob was converted by microwave‐assisted carbonization. The sulfonation temperature was a major factor that influenced the number of SO 3H groups on the catalyst. These active groups benefited the co‐pyrolysis oil yield of nearly 98% at 500 °C for 15 minutes. The obtained oil consisted of aromatic and C 9–C 16alkanes, which was qualified as a bio‐jet fuel.

Читать дальше

/SnO 2

/SnO 2