Business expanded, and Westinghouse bought land east of the city where he erected a larger plant, and in 1890 built a town around the plant. The town was named “Wilmerding,” the name of the family from whom he had bought the land. Unlike other U.S. factory towns of the late nineteenth century, the stores were privately operated, and not by Westinghouse Company. Workers were not bound by a scrip system, and houses were either rented from the company or could be purchased at a modest cost. In addition to the benefits mentioned in the first paragraph of this essay, Westinghouse Company also provided pensions covering the wives and orphans of retirees, sickness and accident benefits, student training courses in the company’s shop, employee incentive plans, and the basic principles of collective bargaining.

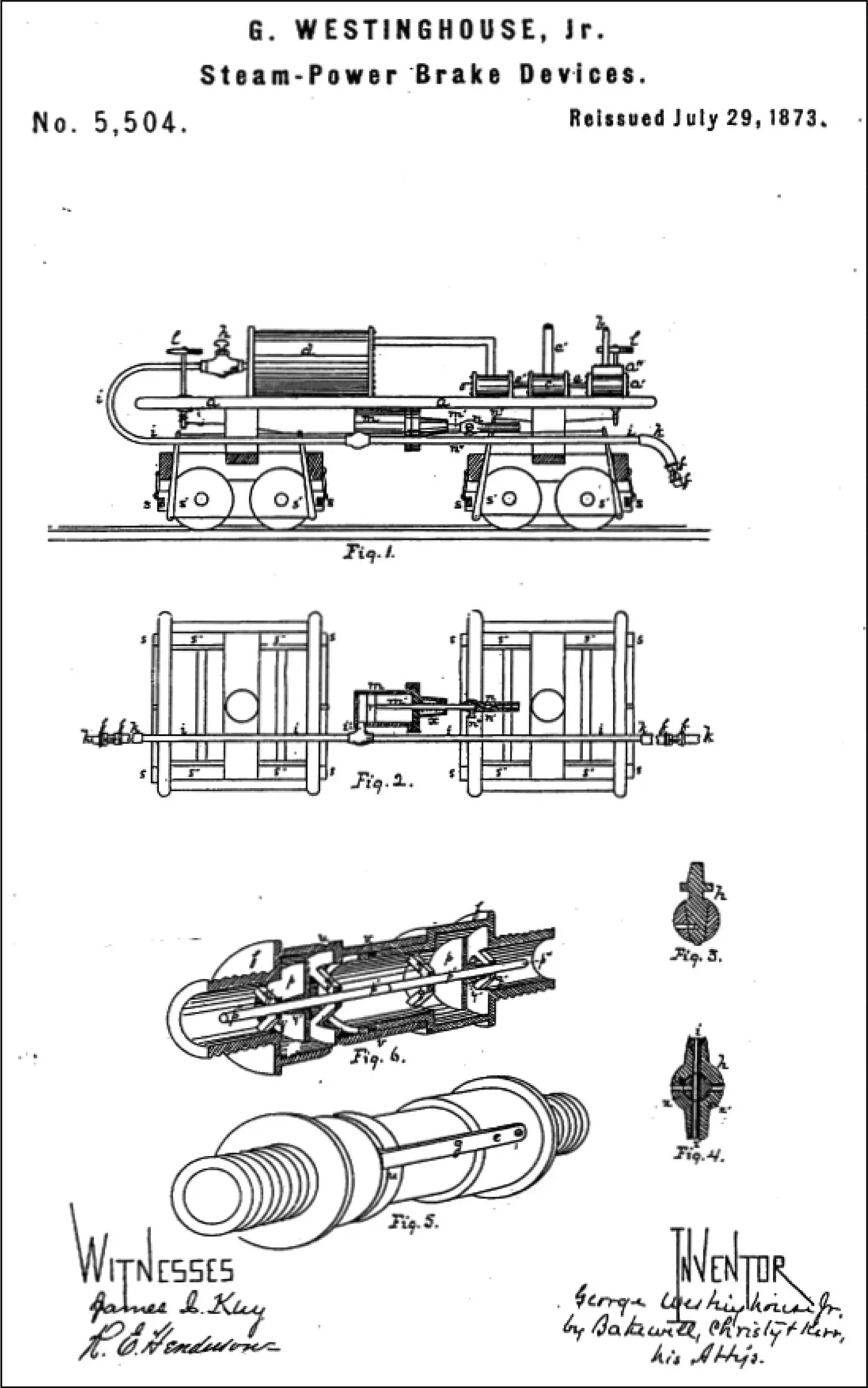

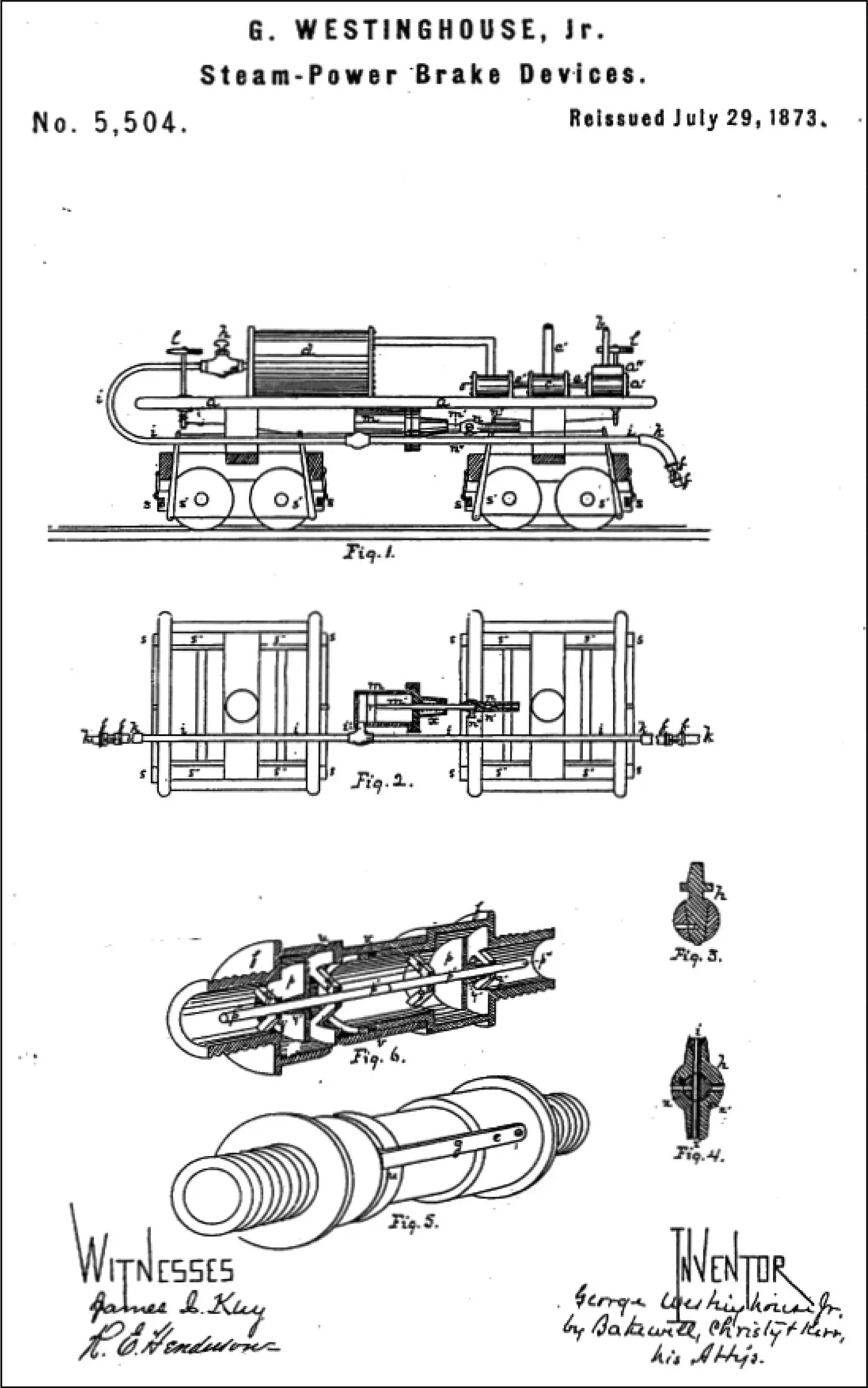

In 1879, Westinghouse invented a pneumatic interlocking railroad signal system to control the increased speed and flexibility that railroads gained by the invention of the air brake. In 1881, he organized the Union Switch and Signal Company to develop and sell his railroad safety and traffic control inventions.

In the mid‐1880s, Westinghouse became interested in electricity and, in particular, the disadvantages of the DC power systems fostered by Thomas Edison. He pursued AC power–generating technology, bought the U.S. rights to Gaulard and Gibbs’ AC distribution system in 1885, and hired William Stanley to improve on the Gaulard–Gibbs “transformer.” In 1886, Westinghouse organized the Westinghouse Electric Company to advance the introduction and use of AC power systems in direct competition with Edison’s DC power systems, as described in more detail in the essay titled “Current Events” following Chapter 36, supra. In 1887–1888, Westinghouse also acquired rights under Nikola Tesla’s AC polyphase system patents, and hired Tesla to work for Westinghouse Electric and develop the AC motor with the rotating magnetic field that Tesla had conceived and had been working on. In 1892, Westinghouse, using Tesla’s AC polyphase system, was awarded the contract to light the “White City,” the 1893 Columbian Exposition in Chicago. Westinghouse’s company also installed the electrical generators to turn the kinetic energy of Niagara Falls into hydroelectric energy. Commercial service of these huge generators began in the fall of 1896. Due to financial problems, Westinghouse lost control of his electric company in 1907, but retained control of his other companies.

George Westinghouse was issued 361 patents in all, and died on March 12, 1914, in New York City. He and his wife are buried in Arlington National Cemetery. In my judgment, George Westinghouse appears to be a successful industrialist who was driven more by the desire that his efforts would benefit mankind than by the drive for money for money’s sake.

INVENTORS AND INVENTIONS

Gideon Sundback

ZIPPER

Elias Howe is recognized as the inventor of the sewing machine, but he also received a patent in 1851 for an “Automatic Continuous Clothing Closure.” However, because his sewing machine was very successful, Howe opted not to pursue his clothing closure invention. Forty‐four years, later Mr. Whitcomb Judson, who also invented a pneumatic street railway, marketed a “clasp locker,” a device that was similar to the 1851 Howe closure. The clasp locker was a complicated hook and eye shoe fastener. Universal Fastener Company was created by Judson to manufacture the new fastener that had its public debut at the 1893 Chicago Columbian Exposition. However, the Judson device met with limited commercial success, because it kept snapping open.

Gideon Sundback was born in Sweden, and, after his electrical engineering studies in Sweden, he moved to Germany, where he studied at the Polytechnic School in Bingen am Rhein. In 1903, he took his engineering exam, and, in 1905, he immigrated to the United States, where he was hired by Universal Fastener Company. He possessed excellent design skills, and, full disclosure, he was married to the plant manager’s daughter. Sundback eventually rose to the position of head designer at Universal Fastener.

Between 1906 and 1914, Sundback produced several improvements on the fasteners previously designed by Howe and Judson. Judson’s fastener was based on hooks and eyes, and Sundback eventually developed an improved version of that product, called the Plako. However, the Plako fastener had a tendency to pull apart, and was no more successful than previous fasteners. Sundback solved the pulling apart problem in 1913 when he invented the first fastener version not based on the hook and eye principle of previous fasteners. Known as “Hookless Fastener No. 1,” he increased the number of fastening elements used in previous fasteners from four per inch to 10–11 per inch. His invention also comprised two facing rows of teeth that were pulled into a single connected piece by a slider. Sundback also increased the opening for the teeth guided by the slider.

In 1914, Sundback developed “Hookless No. 2,” a version of his fastener based on interlocking teeth, which was the same as the modern metal zipper of today. In this fastener, each tooth was punched to have a recessed dimple on its bottom, and a nib or conical projection on its top. The nib on top of one tooth mated with the matching dimple in the bottom of the tooth that follows it on the other side as the two strips of teeth are brought together through the two Y‐channels of the slider. The teeth are ultimately crimped together tightly to form a strong fabric cord defining the selvage edge of the cloth tape that attaches the fastener length to the garment. The teeth on one side are offset by half a tooth’s height from those on the other side. The teeth are held tightly to the cord and tape so that, once meshed, there is insufficient play to allow the teeth to pull apart. A tooth cannot rise up enough on the nib below it to break free, and the top nib cannot become dislodged from the dimple in the tooth above it. Sundback’s U.S. Patent No. 1,219,881 for his Separable Fastener was issued in 1917.

Sundback also created a manufacturing machine for his new fastening device. The machine took a special Y‐shaped wire and cut scoops from the wire, then punched the scoop dimple and nib, and clamped each scoop on a cloth tape to produce a continuous fastener chain. Within the first year of operation, Sundback’s machine was producing several hundred feet, about 100 meters, of fastener per day.

During World War I, Sundback’s separable fasteners were reportedly used in U.S. Navy flight suit prototypes. However, the aviator garments apparently did not work well initially, but the flight suit prototypes created initial interest in these new fasteners in the garment industry.

In 1923, B.F. Goodrich Company developed the name “zipper,” and used the device on their new galoshes that were designed to be worn over dress shoes to keep the shoes dry in wet weather. The term “zipper” became short for “zipper up,” which is a manifestation of the “zzziiip” sound a zipper makes when it is being zipped up. At that time, boots, gloves, and tobacco pouches were the primary use for zippers. It took another 20 years before zippers were commercially noticed by the fashion industry. By World War II, the zipper had achieved wide acceptance for the flies of trousers and the plackets of skirts and dresses.

Читать дальше