Oil containment is a concern in the plant due to a fire hazard. Dry transformers for feeding smaller loads are preferred due to their flexibility to be placed closer to the loads and for being less of a fire hazard. However, since dry transformers are commercially built only up to 3 MVA and at voltages up to 13.8 kV, oil immersed transformers will be ordered for this application. To conform to the NFPA guidelines, a fire‐rated blast wall will be provided between the two transformers (see Chapter 4for details).

In addition, this plant will need several load centers for the LV motors and drives. This can be covered by a number of unit substations with 2/3 MVA, 13.2 kV to 480 V transformers, 480 V switchgear and 480 V MCCs. For explanation, why 13.2 kV is used and not 13.8 kV (see Chapter 11).

Process (pumping, flotation): This facility will need several load centers for LV motors and drives. These loads will be fed from a couple of unit substations with 2/3 MVA, 13.2 kV to 480 V transformers. Each unit substation will include a 480 V switchgear and 480 V MCCs for feeding the LV loads.

Camp: The camp is typically located 3–5 km away from the main substation. An overhead distribution line will be erected to the Camp directly from the main substation. This line may include several other 15 kV circuits that may be going in the same direction. The camp load center will include a 500 kVA, 13.2 kV/ 480 V load center with LV distribution boards. Additionally, the load center will be furnished with one or two small emergency standby diesel generating units connected to the main load center via an automatic transfer switch (ATS) to feed the selected camp essential loads. Two small generators are recommended specifically for the camp due to the remote and challenging living environment.

Tailings: Tailing pumping station is 6 km away. The facility will require a 15 kV overhead line to feed a small 13.8 kV/480 V load center.

Water supply pumping: The manufacturing and process equipment will need fresh water supply either from the natural sources or by trucking and storing in the tanks near the process plant.

Mining: This load may be supplied by a portable DG at an open‐pit mine location.

Auxiliary system: Add HVAC, lighting, cranes, sumps, eat tracing, etc., to the load estimate. These items generally are not shown on the process flow diagrams.

Plant standby generator: A standby DG 1 MW, will be connected to the 13.8 kV bus at the main substation to supply power to the plant essential load. It will automatically be energized and loaded in case of a total loss of the main supply. This may happen due to problems at the utility or a loss of the 230 kV line. The standby generator will supply power to 30% of lighting, heating, some pumping, and other essential and life critical services. It will not provide power to the process, but it will maintain the charge of the plant DC and control systems (see Section 2.10).

2.7 The Key One‐Line Diagram

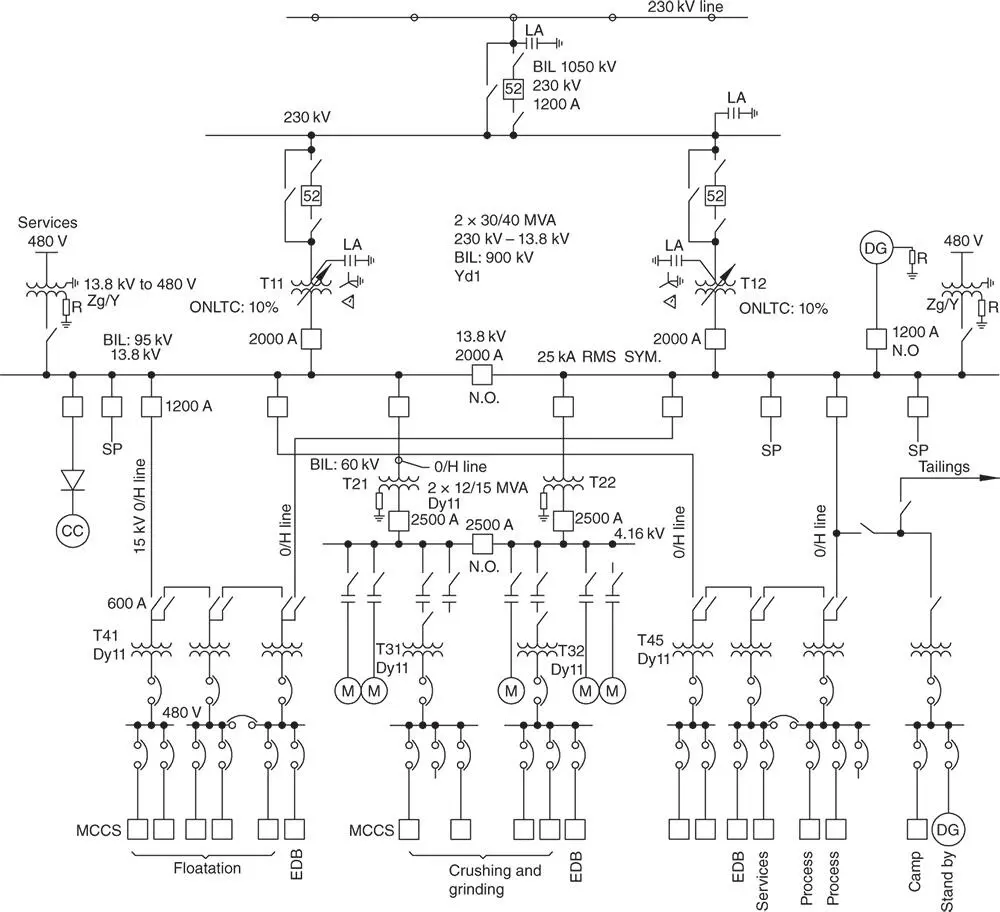

2.7.1 Load Investigation

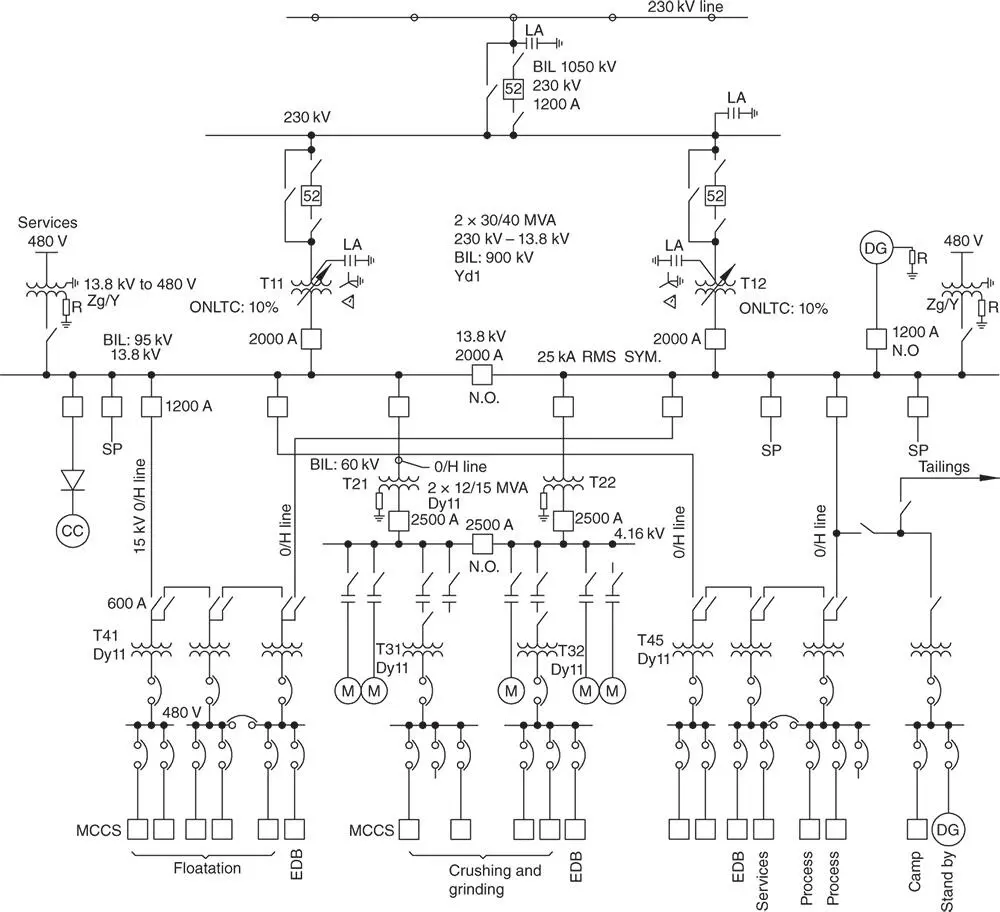

An industrial plant of this magnitude will have approximately 400–500 motors and electrical feeders. Obviously, we cannot extract all these motors and feeders from the flow diagrams, but as the design progresses, and the major equipment is procured, the number of motors and drives generally increases and the load grows. Having gone through the load investigation and the load placement within the plant, we have finally arrived at a point of drawing an overall plant diagram, the key one‐line diagramas shown in Figure 2.7. We will call the feeders drawn above the 13.8 kV drawing line as the incomers and those below the line will be called the plant feeders.

Now we can assign the loads (MW) to each area of the plant and to specific MCCs, separated by different voltage categories, MV and LV. The presentation of the diagram is relatively simplistic, made for the book only. A more comprehensive drawing would be required if prepared for the real project.

Figure 2.7 Key one‐line diagram.

The main 13.8 kV switchgear for the aforementioned project will require about 11 feeder breakers to feed various 4.16 kV and 480 V load centers, three incomers, and a bus tie breaker for a total of 16 breaker and switchgear cells. You will note that the 480 V load centers are looped together to two 13.8 kV breakers from either side of the 13.8 kV bus to enhance reliability of supply of the load centers.

2.7.2 Connected Load – Operating Load

The overall estimate for the connected load( Table 2.2) as part of the conceptual design broken down at voltage levels is as follows:

Of course, the figure given earlier is not the actual operating load. This is yet to be determined. We will arrive at that by using diversity and other load factors.

Having participated in the design of many projects, we have yet to know the actual operating load in relation to the connected load. It surely depends on the type of plant. We would expect that a batch plant would have a higher percentage compared to a mining plant. During the design, it is evident that the connected load far exceeds the expected operating load and far exceeds the power distribution transformer capability. The connected load must be “treated” with several diversity and load factors.

During the commissioning, we do observe the operating currents of the individual drives and note that the actual load factors are considerably lower than projected. This is partly due to the fact that mechanical engineers and suppliers continually oversize the plant motors due to their fears and rounding up to the higher frame sizes to insure flows are adequate and in line with expectations. We have yet to hear an owner complaining that we have overloaded the system, or that we have oversized the system. There always seems to be “a lot of fat” in the system.

Table 2.2 Connected load.

| Voltage |

MW |

| 13.8 kV |

9.5 |

| 4.16 kV |

15 |

| 480 V |

20 |

| Cable and equipment losses |

0.5 |

| Growth (10%) |

5 |

| Connected load |

50 |

Table 2.3 Load list.

| ID |

Name |

kW |

Volt |

Serv. |

LF |

UF |

(DF) |

Load |

| 20AG01 |

Tank#1 Agitator |

11 |

480 |

1 |

0.7 |

1 |

0.7 |

7.7 |

| 15LT03 |

Lighting transformer |

15 |

480 |

1 |

0.5 |

1 |

0.5 |

7.5 |

| 20PU21 |

Tank #1 Supply pump |

30 |

480 |

1 |

0.8 |

1 |

0.8 |

24 |

| 20PU22 |

Tank #1 Supply pump |

30 |

480 |

0 |

0.8 |

1 |

0.5 |

0 |

| 15FA11 |

Crusher building fan |

30 |

480 |

1 |

0.6 |

1 |

0.6 |

18 |

| 15CR01 |

Crusher building crane |

50 |

480 |

1 |

0.4 |

0.1 |

0.05 |

2.5 |

| 21BM01 |

Ball mill |

2000 |

4160 |

1 |

0.7 |

0.6 |

0.7 |

840 |

| 21BM02 |

Ball mill |

2000 |

4160 |

1 |

0.7 |

0.6 |

0.7 |

840 |

| 15WR01 |

Welding receptacle |

60 |

480 |

1 |

0.5 |

0.1 |

0.05 |

3.0 |

|

Connected |

4226 |

|

|

|

Operating |

|

1742.7 |

Abbreviations: ID, identification number; kW, connected load; Serv., unit in service (1) or on standby (0); LF, load factor (<1); UF, utilization factor (<1); DF, calculated diversity factor (Serv *LF*UF).

Читать дальше