1 ...6 7 8 10 11 12 ...30 We deal with this misalignment by proposing a new course framework to integrate Computer Aided Design (CAD), Computer Aided Manufacturing (CAM), and other Information Technologies (ITs) in one course setting. In the framework, the inclusion of engineering disciplines and computer aided technologies are driven by the needs in designing products and manufacturing processes. While the theories in engineering disciplines are used to clarify design and analysis problems, computer aided tools are presented as the corresponding solutions. In addition, the framework is modularized and the course contents can be customized for some specialties.

The current version is customized to meet education needs of students in Mechanical Engineering , Manufacturing Engineering , and Industrial Engineering at junior or senior levels. It consists of three parts: Part I – Computer Aided Design (CAD), Part II – Computer Aided Manufacturing (CAM), and Part III – System Integration . Part I includes Chapter 2 – Computer Aided Geometric Modelling , Chapter 3 – Knowledge‐Based Engineering , Chapter 4 – Platform Technologies , Chapter 5 – Computer Aided Reverse Engineering , and Chapter 6 – Computer Aided Machine Design . Part II includes Chapter 7 – Group Technology and Cellular Manufacturing , Chapter 8 – Computer Aided Fixture Design , Chapter 9 – Computer Aided Manufacturing (CAM) , Chapter 10 – Simulation of Manufacturing Processes , and Chapter 11 – Computer Aided Design of Tools, Dies, and Moulds (TDMs) . Part III includes Chapter 12 – Digital Manufacturing (DM) , Chapter 13 – Direct and Additive Manufacturing , and Chapter 14 – Design for Sustainability (D4S) .

The concepts of CAD, CAM, and system integration are not new; a number of textbooks on these subjects have been on the market for a long time. However, CAD, CAM, and system integration technologies have been greatly advanced recently due to the rapid development of IT and computer hardware and software systems. Most of the available textbooks in relevant subjects become obsolete in terms of design theories, methods, and technical coverages. Modern manufacturing systems in the digital era become ever more complicated, and product and system designs demand more advanced computer tools to deal with the complexity, varieties, and uncertainties. In contrast to other textbooks in similar areas, this book is featured (i) to update computeraided design theories and methods in modern manufacturing systems and (ii) to cover mostly advanced computeraided tools used in digital manufacturing. It will be an ideal textbook for undergraduate and graduate students in Mechanical Engineering , Manufacturing Engineering , and Industrial Engineering and can be used as a technical reference for researchers and engineers in mechanical and manufacturing engineering or computer aided technologies.

Zhuming Bi

Professor of Mechanical Engineering

Department of Civil and Mechanical Engineering

Purdue University Fort Wayne, Indiana, USA

Xiaoqin Wang

Associate Professor of Manufacturing Engineering

School of Mechanical Engineering

Nanjing University of Science and Technology, Nanjing, China

About the Companion Website

The companion website for this book is at

www.wiley.com/go/bi/computer-aided-design

The website includes:

PDFs

PPTs

Scan this QR code to visit the companion website.

1 Computers in Manufacturing

1.1 Introduction

1.1.1 Importance of Manufacturing

The life quality of human being relies on the availability of products and services from primary industry, secondary industry, and tertiary industry. According to the three‐sector theory (Fisher 1939), the primary industry relates to the economic activities to extract and produce raw materials such as coal, wood, and iron. The secondary industry relates to the economic activities to transfer raw or intermediate materials into goods such as cars, computers, and textiles. The tertiary industry relates to the economic activities to provide services to customers and businesses. The secondary industry supports both the primary and tertiary industries, since the businesses in the secondary industry take the outputs of the primary industry and manufacture finished goods to meet customers' needs in the tertiary industry. In contrast to the wealth distribution or consumption in the tertiary industry, the secondary industry creates new wealth to human society (Kniivila 2018).

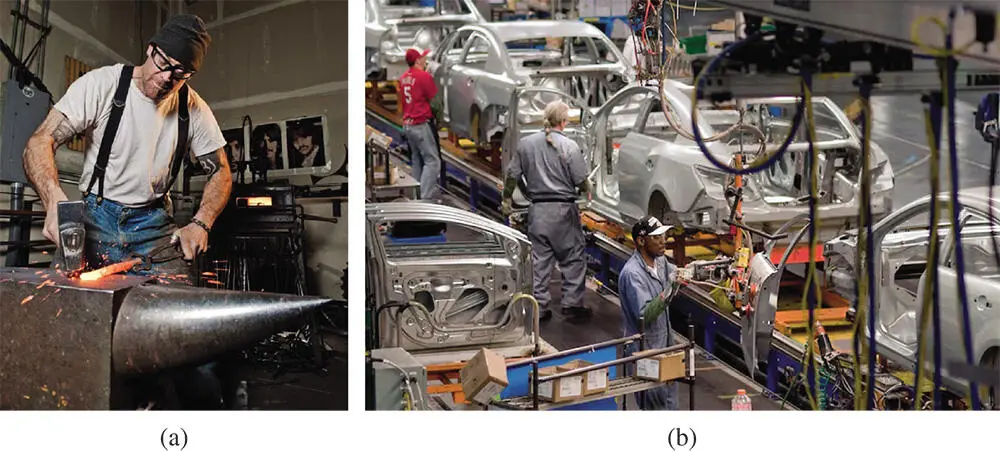

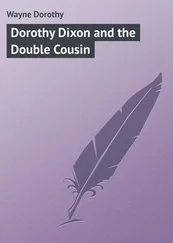

A manufacturing system can be very simple or extremely complex. Figure 1.1a shows an example of blacksmithing where some simple farming tools are made from iron (Source Weekly 2012). Figure 1.1b shows an example of a complex car assembly line, which is capable of making Ford Escape cars (Automobile Newsletter 2012). Despite the difference in complexity, both of them are good examples of a manufacturing system since manufacturing refers to the production of merchandise for use or sale using labour and machines, tools, chemical and biological processing, or formulation (Wikipedia 2019a). Manufacturing is one of fundamental constitutions of a nation's economy. Manufacturing businesses dominate the secondary industry. Powerful countries in the world are those who take control of the bulk of the global production of manufacturing technologies. Over the past hundreds of years, advancing manufacturing has been the strategic achievement of the developed counties to sustain their national wealth and global power. The importance of manufacturing to a nation has been discussed by numerous of researchers and organizations. For example, a summary of the importance to the USA economy is given by Flows (2016) and Gold (2016) as follows:

1 Manufacturers contributed $2.2 trillion with ∼12% of gross domestic product (GDP) to the USA economy in 2015.

2 The manufacturing multiplier effect is stronger than in other sectors. For $1.00 spent in manufacturing, $1.81 is added to other sectors of the economy. Manufacturing has the highest multiplier effect. Gold (2016) argued that the impact of manufacturing has been greatly underestimated; it is supported by the findings of the Manufacturers Alliance for Productivity and Innovation (MAPI) Foundation that the total impact of manufacturing on the economy should be 32% of GDP and that the full value stream of manufactured goods for final demand was equal to $6.7 trillion in 2016.

3 Manufacturing employs sizeable workforces. The manufacturing sector provides ∼17.4 million jobs, or over 12.3 million.

4 Manufacturing pays premium compensation. Manufacturing workers earnt a high average of $81 289 annually in 2015.

5 Manufacturing dominates US exports; the United States is the No. 3 manufacturing exporter.

6 The US attracts more investment than other countries and foreign investment in US manufacturing grows; the foreign direct investment in manufacturing exceeded $1.2 trillion in 2015. New technologies allow manufacturers to alter radically the way they innovate, produce, and sell their products moving forward, improving efficiency and competitiveness.

Figure 1.1A manufacturing system can be very simple or complex (a). Blacksmithing (Source weekly 2012), (b). Ford assembly line at Kansas City (Automobile Newsletter 2012).

Читать дальше