TSA can work both for low and elevated pressures; however, it is usually preferred when the adsorption step is carried out at a low temperature. Consequently, the main advantage of TSA over PSA is its ability to separate efficiently strong‐bonded adsorbates onto adsorbents, as for the case of chemisorption. However, a major drawback of TSA is the high energy intensity of the desorption process compared to PSA. Other alternatives to TSA include microwave swing adsorption (MSA) [14] and electric swing adsorption (ESA) [15] that could offer potential energy savings and faster heating rates; however, these technologies are still at low technology readiness level (TRL).

Generally, TSA is usually preferred for post‐combustion CO 2capture at low temperature and atmospheric pressure, while PSA usually is the right choice for pre‐combustion CO 2capture at elevated temperatures, as in the case for an IGCC plant configuration. As a post‐combustion arrangement, PSA and TSA are assessed as TRL 6.

Adsorption equilibria, kinetics, and regeneration ability are key factors to evaluate the performance of an adsorbent. Fast adsorption/desorption kinetics, influenced by functional groups present, as well as the pore size and distribution in the support, are essential for an efficient CO 2adsorption process and control of the cycle time and the required amount of adsorbent. Other selection criteria include high CO 2selectivity, mechanical strength after multi‐cycling, chemical stability/tolerance to impurities, high availability, and, lastly, low costs.

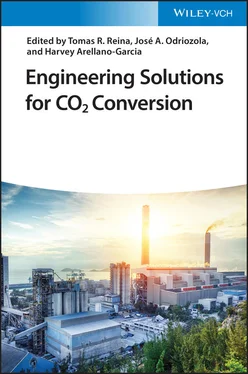

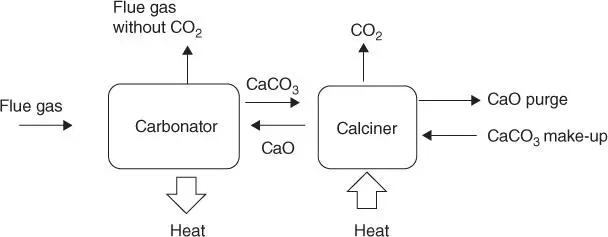

Figure 1.5Calcium looping system as post‐combustion configuration.

Source: Adapted from Abanades [16].

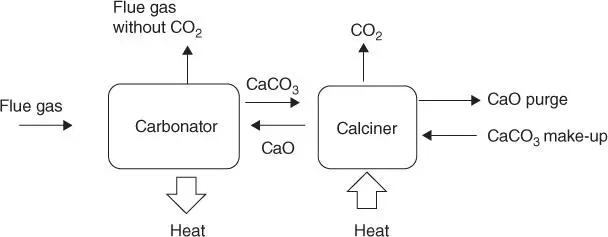

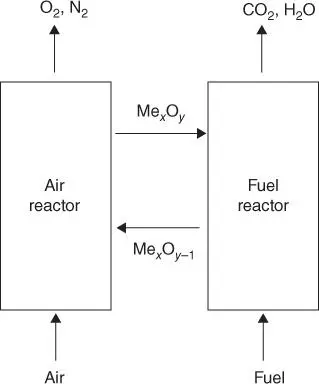

Figure 1.6Chemical looping combustion. Me xO y/Me xO y−1denotes the recirculation oxygen carrier material.

Source: Adapted from Abanades et al. [17]. © Elsevier.

1.2.4.2 High‐Temperature Solids Looping Technologies

The most common types of high‐temperature solids looping technologies are calcium and chemical looping combustion. Calcium looping uses CaO as a sorbent, which produces CaCO 3at approximately 650 °C ( Figure 1.5). Chemical looping is a two‐step conversion process where the fuel reacts with almost pure O 2as in the oxyfuel process, while a metal oxide acts as an oxygen carrier and reacts with the fuel, obtaining CO 2and water ( Figure 1.6). In both cases, the metal oxide or CaO is regenerated.

Note that calcium looping can be considered as post‐combustion or pre‐combustion, while chemical looping can be considered as oxy‐combustion or pre‐combustion depending on the configuration [16].

Because of the high operation temperature, the advantage of this process is the potential recovery of energy for steam production, which can be used for additional power production and reduce the efficiency penalty in the power plant.

Calcium looping has shown a significant evolution over the past 15 years from lab scale to pilot testing, reaching a TRL of 6. The main research focus to cut down the costs over the next years is on the sorbent, reactors (configurations and interconnections), and process designs [17]. If used in the industrial sector, calcium looping can be beneficially integrated in the cement production facility because of the use of solids from the capture system in the production. In this regard, the CLEANKER project aims to scale up a calcium looping process in a cement production environment, which will increase the TRL of this technology up to 7. 4

Chemical looping has reached a TRL of 6 as oxyfuel arrangement while a TRL of 3 as pre‐combustion system. The main research areas on chemical looping are focused on the reactor design, oxygen carrier development, and prototype testing. Moreover, more than a thousand materials have been tested at the laboratory scale. At a larger scale (0.3–1 MW), the accumulated operational experience is more than 7000 hours [17]. A detailed review of the main process routes under development within the chemical looping systems is included in Ref. [17].

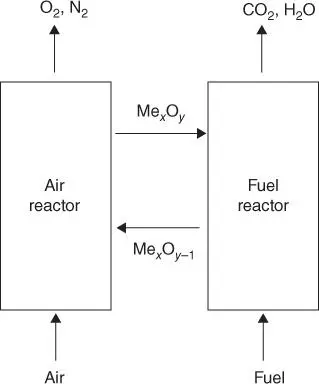

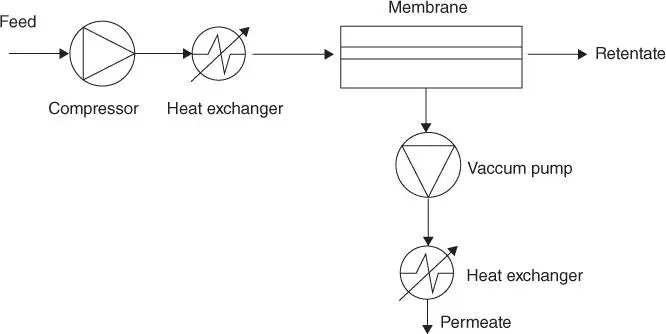

Membranes are porous structures able to separate different gases at different rates because of their different permeation [8]. These can be used not only in post‐ and pre‐combustion processes but also in oxyfuel for oxygen separation. In post‐combustion, the main interest in these systems is their low energy requirements compared to the traditional chemical absorption process.

The energy needs are reduced to those from the compressor and vacuum pump. Moreover, membrane systems are easy to start and operate, have no emissions associated, and are modular, offering installation advantages [8]. However, the separation mechanism of membranes is based on the difference of CO 2partial pressure. In post‐combustion, because of the relative low CO 2concentration in the flue gas to be treated (approximately 4–12% for power plants), this driving force would not be enough to achieve high CO 2capture ratios through simple configurations. However, membranes could offer advantages for partial capture arrangements and generally more complex arrangements are used to reach a full capture rate (90%). In pre‐combustion, because of the higher partial pressure of CO 2in the gas to be treated, membranes can be more effective. In any case, the gas containing CO 2must be cooled down to meet the temperature limitations of the membrane [18] and that could be a drawback ( Figure 1.7).

Figure 1.7Scheme of a single‐stage membrane system.

Source: Adapted from Mores et al. [18].

Table 1.1Advantages of each type of membrane [21].

Source: Adapted from Wang et al. [21].

| Type of membrane |

Advantages |

| Ceramic |

Good selectivity–permeability Easier to manufacture larger areas |

| Polymeric |

Good thermal stability and mechanical strength |

| Hybrids |

Aiming to show the advantages of both ceramic and polymeric membranes |

There are two main characteristics to define a membrane material for CO 2capture: permeability, which will impact on the CO 2separation ratio and selectivity, which will define the CO 2concentration in the output gas. From a techno‐economic perspective, the optimum values for selectivity and permeability would be a function of the gas to be treated, as studied in Ref. [19]. The ratio of the permeability to the thickness of the membrane will be of high importance as that will characterize the permeance (commonly measured as gas permeation units [GPU]). To maximize the permeance without impacting the mechanical stability, the membranes are typically a dense layer supported by a porous layer [20].

The membrane materials can be divided into ceramic, polymeric, and hybrid ( Table 1.1). Moreover, the design of the membrane‐based system will be a key factor on the separation process. Firstly, the membrane module will be the key factor. The main modules for polymeric membranes are described as a spiral wound, a hollow fiber, and an envelope [21].

The majority of the membranes used currently for post‐combustion are based on polymeric materials [20], and a large list of polymers have been studied in the literature, including polyimides, polysulfones, and polyethylene oxide. The most advanced processes have reached currently a TRL of 6. Because of the modularity membranes offer, although sometimes predicted, it is not clear if there will be a fast development toward higher TRLs [21].

Читать дальше