America’s fluorocarbon refrigerants market was valued at $2.5 billion in 2013 and is estimated to reach $3.1 billion by 2019, at a CAGR of 3.6%, for the given period. The growing demand for chilled and frozen food and beverages has fuelled demand for commercial refrigeration, consequently driving demand for fluorocarbon refrigerants in the region [12]. The global refrigerants market size was US$22.9 billion in 2018 and is projected to reach USD 31.0 billion by 2023, at a CAGR of 6.2% between 2018 and 2023 [13].

Blowing agent application accounted for over 9.5% of the total volume in 2014 and is likely to witness gains at CAGR of over 3% from 2015 to 2024. Fluorochemicals produce hydrogen fluoride, which is broadly used in production of fluorinated hydrocarbons, which serves as foam blowing agents. This is used in wide range of plastics like polystyrene and polyurethane for improving their insulation properties in industrial and domestic appliances such as cooling plants, food processing equipment, refrigerators, cold storage rooms and packaging materials [11].

The largest refrigerant manufacturing countries are China (689,000 metric tons), the USA (604,000 metric tons), Japan (81,000 t metric tons), Germany (32,000 metric tons), India (30,000 metric tons) and the Netherlands (30,000 M tons). The refrigerant quantities produced are not just used in the ventilation, air conditioning and refrigeration technology sector however, but are also used for other industrial processes such as those carried out for aerosols, foams and insulation [14].

The world’s most important refrigerant manufacturers include Arkema, Chemours, Honeywell, Solvay, Daikin, Showa Denko and Mexichem, as well as numerous Chinese manufacturers, some of which are Sinochem Lantian, Shandong Dongya and 3F Fluorochemical Industry, a joint venture between DuPont and Zhonghao New Materials [14].

1.3 Production and Consumption Statistics of Fluoropolymers

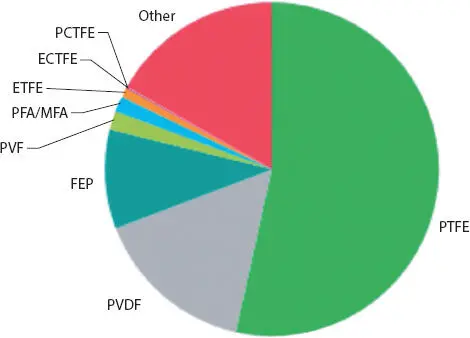

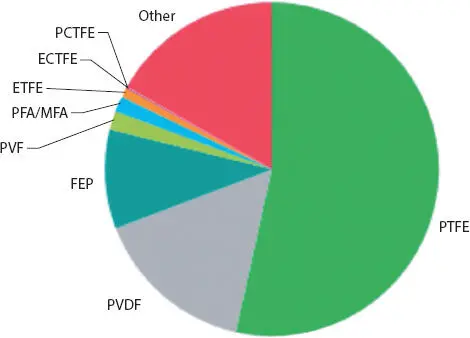

Extreme properties of fluoropolymers have made them among the most useful modern materials. They provide: nonstick surfaces for cookware and industrial products, waterproofing surface treatments for clothing and other substrates, stain barriers for textiles, high-purity fluid handling in the form of tubes, pipes, gaskets, seals and thread sealant tape, medical devices, wire and cable insulation jackets, high-performance coatings, back sheet for photovoltaic panels, films and membranes for technical, waterproof clothing, and industrial applications. Figure 1.7 shows the breakdown of consumption of fluoropolymers by type.

Figure 1.7Breakdown (2018) of worldwide consumption of fluoropolymers by Type [15].

PTFE at 58% (in 2015) has the highest consumption volume among fluoropolymers. Significantly, PTFE is the oldest product of all fluoropolymers its commercialization dating back to 1946. Polyvinylidene fluoride (PVDF) has the second highest volume (under 20%) followed by perfluorinated ethylene propylene copolymers (FEP) at about 10%. PVDF and FEP are fastest growing fluoropolymers.

A number of fluoropolymers are consumed at lower volumes including: polychlorotrifluoroethylene (PCTFE), ethylene tetrafluoroethylene copolymer (ETFE), pefluoropropyl vinyl ether copolymer (PFA), pefluoromethyl vinyl ether copolymer (MFA), polyvinyl fluoride (PVF), ethylene chlorotrifluoroethylene copolymer (ECTFE), tetrafluoroethylenehexafluoropropylene-vinylidene fluoride terpolymer (THV), chlorotrifluoroethylene vinylidene fluoride copolymer, CTFE-VDF (<15% CTFE), and amorphous fluoropolymers. “Other” in Figure 1.1 includes fluorosilicones, fluorinated polyimides and polyamides, fluorinated acrylic polymers, polyurethanes and amorphous fluoropolymers and others.

Consumption of fluoropolymers, fluorocarbons, inorganics and specialties expected to reach 5.49 million tons by 2024, growing at a CAGR of 4.6% from 2015 to 2024 [11]. Global fluoropolymer market in terms of revenue was at $7.2 billion in 2012 and is expected to reach $9.8 billion by 2018 and to US$11.5 million by 2025. Projections for future growth rate of fluoropolymer consumption are in the annual range of 5.2-5.7%. Global consumption volume is projected to grow from 295 kT (1,000 metric tons) in 2014 to over 380 kT by 2019 [16].

China is the by far the most dominant consumer of PTFE, accounting for about 44% of world consumption in 2015. The United States and China each use about 30% of other fluoropolymers [17]. The historical growth rate of PTFE in China has been around 7.5% per year while the rest of fluoropolymer have grown at a rate of 15%.

Fluoropolymer consumption is relatively small in India. The entire value in 2014 was $100 million, which is expected to $250 by 2022 [18].

1.4 Production and Consumption Statistics of Fluoroelastomers

Fluoroelastomers are divided into perfluorinated and partially fluorinated polymers. They possess a combination of good chemical resistance, excellent electrical insulation properties and favorable mechanical properties. Fluoroelastomers are highly weather resistant and can function under extreme temperature and pressure.

Applications of fluoroelastomers are increasingly because of the performance advantages these materials offer. They have a combination of physical and chemical properties, comprising excellent chemical resistance, high temperature stability, and good dielectric properties. Fluoroelastomers are extensively used in industrial applications involving severe process conditions. The special properties and relatively low production volume, compared with engineering resins, have kept fluoroelastomer prices are fairly high [19].

Based on volume (base raw material), China accounted for 33% of world consumption in 2018, with Europe and the United States accounting for 19% each, and Japan for 9%. These four regions represented about 80% of the world consumption of fluoroelastomers in 2018 [20].

Fluoroelastomer market size was valued at US$1.15 billion in 2016, US$1.21 billion in 2017 and is projected to reach US$1.64 billion by 2022, representing a CAGR of 6%. Asia-Pacific, with its thriving economies and rapidly expanding populations experienced the fastest growth rate between 2014 and 2019 [19]. Fluoroelastomers consumption is estimated at 24.0 kilo tons (kT) in 2014 reaching 30.4 kT by 2019.

China accounted for 33% of world consumption in 2018 mostly because of growth in its automobile production. Europe and the US account for 19% each, and Japan for 9%. These four regions represented about 80% of the world consumption of fluoroelastomers in 2018. Fluorocarbon elastomers (FKMs) account for about 92% of the world market for fluoroelastomers. Fluorosilicones account for almost 8% of the world market for fluoroelastomers.

1.5 Production and Consumption Statistics of Fluorinated Coatings

Fluoropolymers produce high-performance coatings for harsh industrial environments; mar-free coatings for touch screen electronic devices, architectural and marine coatings and cookware coatings. The coatings are applied as powder or liquid dispersions. Major examples of coating fluoropolymers include PTFE, PFA, FEP, PVF and PVDF. China and the U.S. are the largest consumers of fluoropolymer coating, while Italy, Japan, and the Germany are other key markets for fluoropolymer coating consumption.

The fluoropolymer coatings market is estimated to reach $2 billion in 2025 indicating annualized growth of 6% between 2019 and 2025. PVDF based coating systems are highly durable coating systems extensively used for coating architectural aluminum surfaces as well as post-formed steel sheets (metal coils). North America fluoropolymer coating market is expected to be the largest market, significantly growing over a CAGR of 5.0% [21].

Читать дальше