and

(3.26)

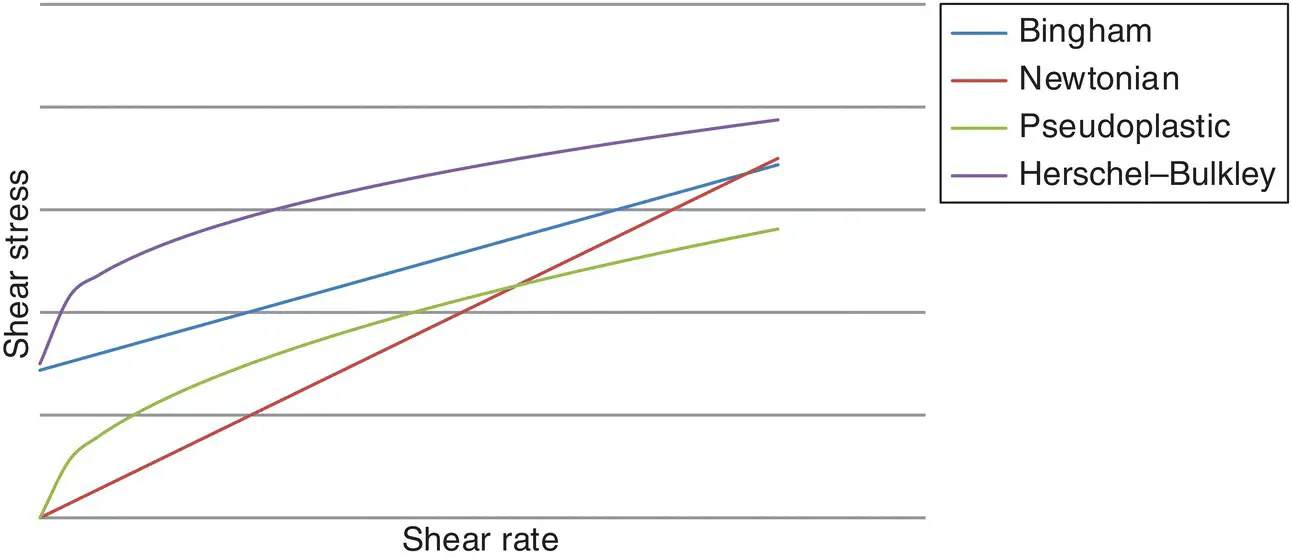

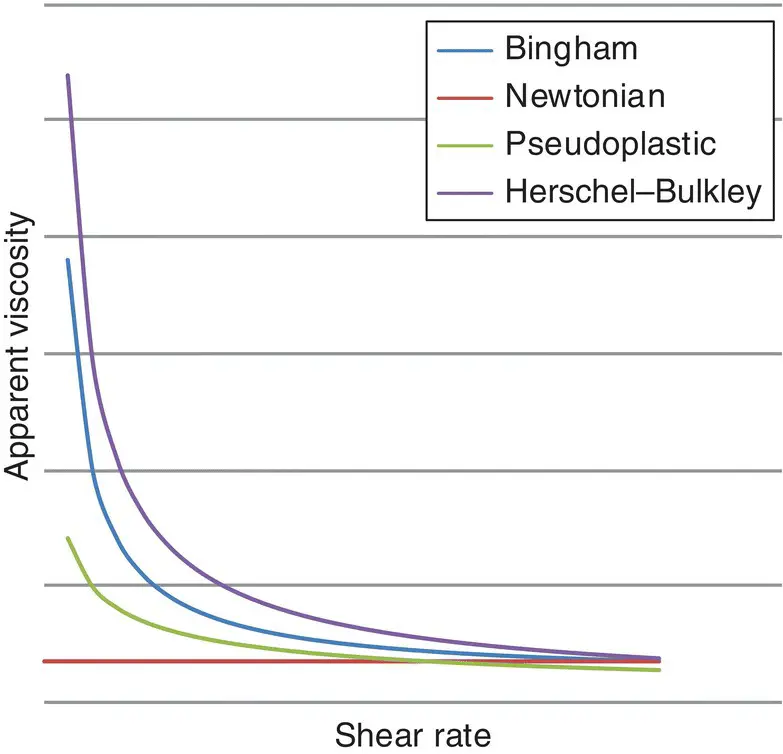

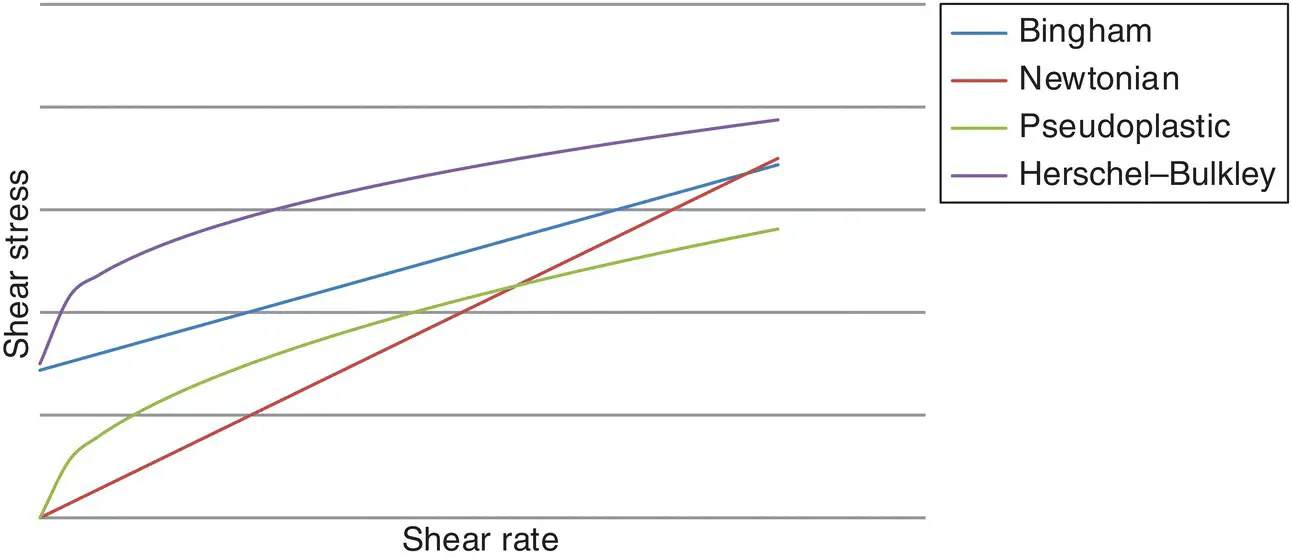

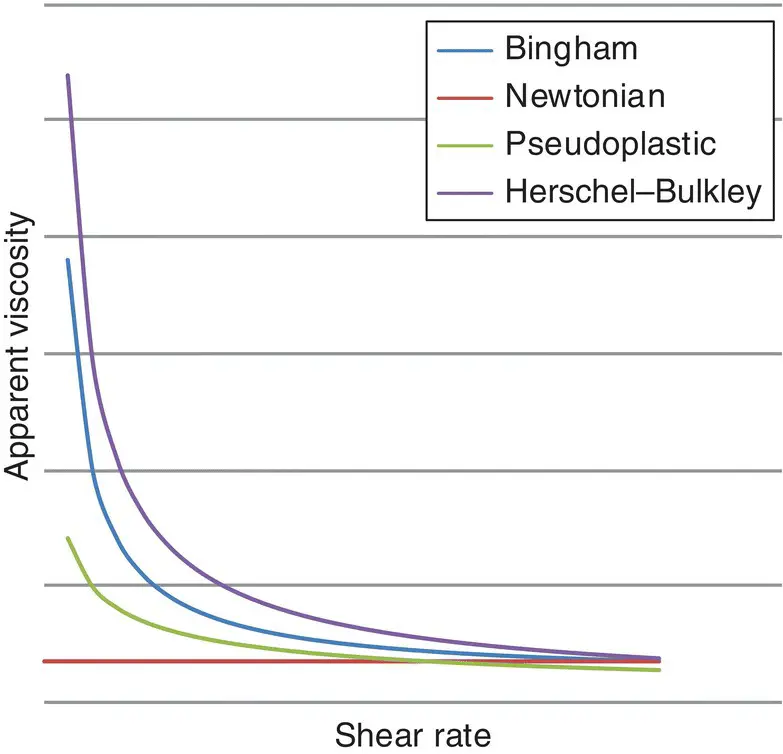

One may recognize that all three previous models are special cases of the Herschel–Bulkley model, making this the most versatile model commonly in use.

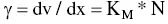

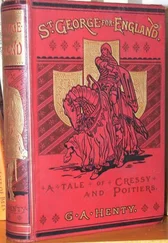

These four models are described visually in Figures 3.8and 3.9

Figure 3.8 shear stress curve.

Figure 3.9 viscosity curve.

Impeller Apparent Viscosity

In laminar and transition flow, the apparent viscosity at the impeller can be evaluated using the average shear rate:

(3.27)

where K Mis the Metzner–Otto constant. There are some disagreements about what that constant is for various impellers. Table 3.1is an average of some of the published numbers.

In turbulent flow, the shear rates may be higher, so the apparent viscosity may be less for most fluids.

A Bit of Impeller Physics

Though we will get into impeller details more in Chapter 5, since this chapter is on the fundamentals, we will describe the basic physics of impeller behavior.

Some have said that some impellers invest their power more as flow, and others invest it as shear. As we will see below, this is an erroneous description.

Basically, a rotating impeller moves fluid. Agitation and gas dispersion are side effects of how much fluid is moved and how it moves it. But the macro relationship is very simple: power = flow times head, same as for pumps. Theoretical velocity head is proportional to tip speed squared or discharge velocity squared, though actual head produced depends on many other factors. Head is related to shear as well, as maximum shear depends on tip speed. So, power is more like a product of flow times shear squared, rather than a sum of flow and shear.

Some talk about the ratio of flow to power as an impeller characteristic. This, too, is erroneous, as, for a given impeller size in turbulent flow, flow is directly proportional to shaft speed but power is proportional to shaft speed cubed. Therefore, flow/power diminishes as shaft speed increases. It approaches infinity as shaft speed approaches zero. Likewise, in laminar flow, power is proportional to shaft speed squared. So, there is no attribute of a flow/power ratio for any particular impeller. It depends on the specific application.

Table 3.1 Metzner–Otto constants.

| Impeller type |

K M |

| Propeller |

10 |

| Low solidity hydrofoil |

10 |

| High solidity hydrofoil |

11 |

| Pitched blade turbine |

11 |

| Radial turbines |

11.5 |

| Chaos (reversing pitch) turbines |

40 |

So, if we were to want to primarily create flow and minimize power, how would we do it? Let’s start with impeller design, based on the flow vs. head relationship. We want to minimize the head term. We will look at several design attributes and the limitations imposed on them.

One attribute is the number of blades. Increasing the number of blades increases the flow, but it also increases the head, as the wake of each blade creates some degree of additivity for the net pressure, as the discharge flow will be moving at a higher velocity as we add blades. So, from a flow‐for‐power maximization standpoint, the optimum impeller would have only one blade. But there is a reason why we seldom see one‐bladed impellers: we prefer not to break the shaft. The hydraulic imbalance would be huge! Hydraulic forces are still quite large for two‐bladed impellers, so they are quite uncommon except in transition flow regimes, and even then, there will usually be several impellers, with the orientation staggered to minimize the bending moment on the shaft. Most “high flow” or hydrofoil impellers have three blades, because this is the minimum that has reasonable hydraulic stability. Using more than three blades improves hydraulic stability somewhat, but at the price of requiring more power for the flow produced.

Another attribute is blade chord angle from the horizontal plane. If the blades were infinitely thin, a zero degree angle would produce no flow and draw no power, save that created by skin drag on the blade surface. As the angle increases, flow increases and so does power, so a very shallow angle will create the most flow for the power. However, the absolute flow produced may be too small for a given diameter and speed. So, either the diameter would have to be increased or the shaft speed would have to be increased. But we are confined in diameter by the tank, so we cannot always increase the diameter; a D/T value of greater than 1 does not work very well. So, we would have to increase shaft speed in some cases in order to use a very shallow angle. But increasing shaft speed also increases head and power, negating the desired power savings from a low angle. The end result is that hydrofoil impellers available in the marketplace generally have chord angles between 15 and 30°, with 20–25° being most common. The power number range is about 0.2–0.4, with 0.3 being most common. The chord angle must never be greater than the stall angle, which is about 37° in water, or boundary layer separation will occur, greatly increasing power draw. For example, a 45° pitched blade turbine will require almost three times the power as a hydrofoil to create the same flow at the same shaft speed.

A third attribute is blade width or a related measure: impeller solidity (will be defined more in Chapter 5). As blade width increases, so does pumping, but power also increases due to higher discharge pressure. So, most high solidity impellers are used for applications that are not just about creating flow.

One of the most important attributes is shaft speed, and this applies to any impeller type. A small impeller rotating at a high speed can create the same flow as a larger impeller rotating at a slower shaft speed. The smaller impeller has a smaller discharge area; hence, its mean discharge velocity will be higher, and thus, the discharge head will be higher. Therefore, it requires more power to produce the same flow. For flow controlled applications, significant power savings can be achieved by using larger impellers at slower shaft speed. Sometimes, the capital cost is higher, but the payback time is usually a matter of months.

Of course, not all agitator design problems are flow controlled. The main application in this book, gas–liquid dispersion, is closer to being turbulent eddy dissipation controlled than anything else. So, in most cases, the power requirements will be governing, and impeller design will focus on other things besides flow.

This chapter has presented basic material that all must know and understand in order to continue into the details required of fermenter design. It can be referred to as needed while reading the rest of the book.

COff bottom clearanceCPHeat capacity at constant pressureDImpeller diameter, edge to edgeDSSwept diameter, or point‐to‐point diagonal diameterdv/dxShear rateFdDimensionless hydraulic forceFhHydraulic forceFTImpeller axial thrustgGravitational accelerationhConvective heat transfer coefficientkThermal conductivityKMMetzner–Otto constantMViscosity coefficientNShaft speedNAAeration number; also called gas flow numberNBDimensionless blend timeNPPower numberNQFlow or pumping numberNReReynolds numberNTThrust NumbernPower law exponentnbbaffle numberOImpeller offset from tank center linePPower drawPgGassed power drawPuUngassed power drawQImpeller discharge rate; also called pumping capacityQgActual gas flow at the impellerSImpeller spacingTTank DiameterTqImpeller torquetbBlade thicknessWActual blade widthWPProjected blade widthwbBaffle width, calculated normal to tank wallvLiquid velocityZLiquid height

Читать дальше