(3.15)

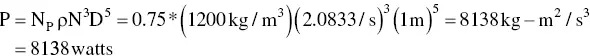

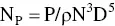

Rearranging to calculate power:

(3.16)

Since it is more common to think of power in kW, this would become 8.13 kW. An 11 kW motor (a standard motor rating) would be ample to power this impeller under these conditions.

Example 2: Pumping Calculation

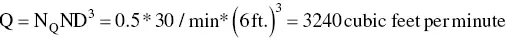

A tank has a hydrofoil impeller of 6 ft. diameter rotating at 30 rpm. It has a known pumping number of 0.5. How much fluid will it pump?

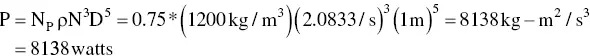

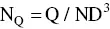

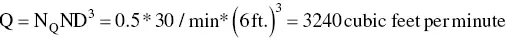

We do not have to do a unit conversion for this one. The units used merely determine the resultant pumping units. Equation (3.5) defines pumping number and is reproduced below:

(3.17)

Rearranging to calculate Q (pumping rate), we get:

(3.18)

Had we used SI units, the calculated pumping capacity would have been expressed as m 3/s, but the physical quantity represented would have been the same.

Example 3: Blend Time Calculation

This really only gets interesting in transition flow, where dimensionless blend time varies with Reynolds number. But let’s suppose we have an impeller with a dimensionless blend time of 10. How quickly would it blend the tank operating at 30 rpm?

If τ*N =10, τ = 10/N = 10/30(1/min) = 1/3 min = 20 s. Note that one can use any units for shaft speed; the resultant blend time units will be determined by this. Note also that as long as the dimensionless blend time is fixed, the result is independent of tank size. This means, for a given D/T and Reynolds number, the blend time at 30 rpm will be the same in any size tank. However, the P/V goes up exponentially when trying to keep the same D/T and the same shaft speed. So, designing for the same blend time in a large tank as a small one can be problematic.

It is not the purpose of this book to be a treatise on rheology. Indeed, many books have been written on the subject. However, due to the extreme difficulty of dispersing gases into viscous liquids, highly viscous liquids are not used or produced in industrially significant fermenters. (I know, some will object, saying they have viscous fermentations. But it is a matter of perspective. While a Gellan gum fermentation may seem viscous to someone operating a fermenter, it doesn’t seem so viscous to those in the polymer industry. But they do not disperse gas into plastic or synthetic rubber melts. The difference is that a very high fermentation viscosity may be 5000 cP at the impeller, whereas in the polymer industry, they may see hundreds of thousands or even several million cP.)

Therefore, we will focus on a few simple models that do an adequate job of describing the behavior of fermentation broths. We will look at shear stress versus shear rate and assume that normal (i.e. at right angles to the shear plane) stresses, such as found in viscoelastic fluids, do not apply. We will also confine ourselves to time‐independent models, because the fluids in fermenters are always under shear and in a quasi‐steady state.

Newtonian fluids are those which have a shear stress that is directly proportional to shear rate (also called velocity gradient). Mathematically, this can be represented as:

(3.19)

where μ, the coefficient on shear rate, is also known as viscosity. This can be arranged to:

(3.20)

Most low viscosity fluids (<50 cP) are Newtonian. Intermediate and even some high viscosity fluids can be Newtonian if they are true solutions, especially if they are solutions of small molecules. For example, honey and corn syrups are often Newtonian even at 30 000 cP. Some silicone solutions are Newtonian even at 20 000 000 cP, but this is quite rare. Most suspensions of more than 5–10% solids exhibit at least some non‐Newtonian behavior. High solids slurries can be very non‐Newtonian.

Low‐solids fermenter broths operating in a water‐like fluid are usually Newtonian. High solids broths may not be, and those containing both an aqueous and an oil phase usually are not. But the overall viscosity for most fermenter broths is less than 1000 cP. The exception is some filamentous broths and those containing soluble gums, such as Xanthan. Chapter 12will cover these in more detail.

Pseudoplastic or Shear Thinning, Model (Aka Power Law Fluid)

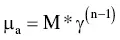

These fluids are called shear thinning because the slope of the shear stress vs. shear rate curve decreases as the shear rate increases. The behavior may be described by a power law model:

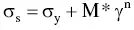

(3.21)

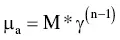

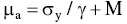

The exponent n is called the power law exponent. When it has a value of 1, the equation reverts to Newtonian. When it is less than 1, it is shear thinning. While it can be greater than 1, which would mean a shear thickening behavior, I have never seen a shear thickening fermenter broth. The apparent viscosity can be expressed by dividing by the shear rate on both sides of the equation:

(3.22)

where M is the viscosity coefficient, or the viscosity at a shear rate of 1 (usually in units of 1/s).

Many fermenter broths exhibit this behavior at high cell density loading, or if there is a significant solids content in the broth.

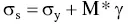

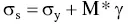

These fluids exhibit a yield stress. That is, until the fluid is exposed to a certain minimum shear stress, it will not move. Examples include some high solids slurries, toothpaste, and any fluid that can hold some of its shape after being disturbed. Above the yield stress, Bingham fluids exhibit a constant slope. Mathematically:

(3.23)

and

(3.24)

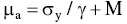

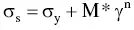

These fluids combine a yield stress with shear‐thinning behavior above the yield stress:

(3.25)

Читать дальше