4.3 Alternative Assessment Methods

Alternatives to direct measurement of optical radiation may be needed when reliable measurement instruments are not available or when installation of a source is being planned or designed. Alternative methods include calculations of radiometric values and use of lamp classifications. Other source‐related guidelines, such as the UV Index (UVI) for solar radiation and shade numbers for welding, are discussed in Section 6.

4.3.1 Calculation of Effective Radiometric Values

Lamp manufacturers should be able to provide spectral distribution data on potentially hazardous lamp output in the range 200–1400 nm expressed as spectral radiant power, spectral radiance, spectral radiant intensity, or spectral irradiance (42). The spectral radiant exitance of a blackbody source such as a furnace can be calculated using Planck's formula (Eq. (9)). The spectral distribution of the source can then be weighted by the appropriate spectral weighting function for the biological effect of interest, yielding an effective radiant power, effective radiance, effective intensity, effective radiant exitance, or effective irradiance, as the case may be.

If the relevant exposure guideline is expressed in terms of effective irradiance at the exposed skin or eye, that effective irradiance can be calculated based on the spatial characteristics of the source and the geometry of exposure. For a point source (i.e. an isotropic source with dimensions that are very small relative to the distance r between the source and the exposed surface), the effective irradiance can be calculated from the effective radiant power or effective radiant intensity using the inverse square law (Eq. (6)). For a flat Lambertian source of area A swhere r is at least five times greater than the longest dimension of the source, the effective irradiance may be calculated from the effective radiance using Eq. (8). Calculation of irradiance from a cylindrical source, such as a low‐pressure mercury‐vapor tube used for a germicidal lamp or a “black light,” involves more complicated geometric considerations. An example of such a calculation may be found in the American National Standards Institute/Illuminating Engineering Society of North America (ANSI/IESNA) Recommended Practice for Photobiological Safety for Lamps and Lamps Systems – Measurement Techniques (43).

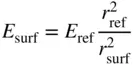

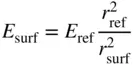

If the source data are reported in terms of spectral irradiance, the manufacturer should provide information on the geometric configuration at which the spectral irradiance was measured. If the measurement distance exceeded five times the longest dimension of the source, then the following version of the inverse square law can be used to calculate the effective irradiance at the exposed surface of the skin or eye, E surf:

(23)

where r surfis the distance between the source and the exposed body surface, E refis the effective radiance under the measurement conditions, and r refis the measurement distance.

TABLE 2 Illuminating Engineering Society of North America Risk Group classification criteria (44).

| Hazard |

Exempt Group |

RG‐1 very low risk |

RG‐2 low risk |

RG‐3 high risk |

|

Exposure limit will not be exceeded within a period of |

|

| Actinic UV hazard |

8 h |

10 000 s |

1000 s |

Fails RG‐2 criterion |

| UV‐A hazard |

1000 s |

300 s |

100 s |

Fails RG‐2 criterion |

| IR‐cornea/lens hazard |

1000 s |

100 s |

10 s |

Fails RG‐2 criterion |

| Retinal thermal hazard (arc sources) |

0.25 s |

n/a |

n/a |

Fails Exempt Group criterion |

| Blue‐light hazard |

10 000 s |

100 s |

0.25 s |

Fails RG‐2 criterion |

| IR‐retinal hazard, non‐lighting sources |

810 s |

10 s |

n/a |

Fails RG‐1 criterion |

h, hour; s, second.

4.3.2 Lamp Classifications

Radiation‐emitting devices, including optical radiation sources, are subject to regulation in the United States by the U.S. Food and Drug Administration (FDA) through its Center for Devices and Radiological Health. The FDA has not established a classification system, analogous to its laser classification system, for noncoherent optical radiation sources.

In the absence of governmental regulations requiring safety‐related classification of all lamps, the IESNA has published a voluntary guideline, ANSI/IES RP‐27.3, Recommended Practice for Photobiological Safety for Lamps and Lamps Systems – Risk Group Classification and Labeling (44). This recommended practice applies to all electrically powered sources emitting radiation between 200 and 3000 nm, except for LEDs used in fiber optic communications systems and lasers. Laser‐driven broadband light sources are included under the standard.

Under the RP‐27.3 recommended practice, the lamp manufacturer should evaluate the lamp for potential to exceed exposure guidelines for UV hazards, blue‐light hazard, IR‐corneal/lens hazard, and retinal thermal hazards. The spectral weighting functions and exposure limits are similar to current ACGIH guidelines (13, 18). An exception is the retinal thermal hazard for IR sources with weak visual stimulus, where the RP‐27.3 recommended practice uses an unweighted radiance. Based on these evaluations, a lamp is classified into one of four risk groups (RGs) – Exempt Group, RG 1 (very low risk), RG 2 (low risk), and RG 3 (high risk) – based on the potential for exceeding an exposure limit for one of these hazards within specified exposure durations. The criteria for RG classification are summarized in Table 2. The manufacturer is required to label packaging for lamps classified as RG‐1, RG‐2, and RG‐3 with appropriate statements prescribed in the RP‐27.3 recommended practice, including instructions on limiting the duration of exposure to the lamp and information that the lamp emits UV or IR radiation.

In a global context, the International Electrotechnical Commission's IEC 62471:2006 standard, which was based on the ANSI/IES RP‐27 standards, has been adopted as a regulatory requirement by the European Union (EU) and other countries and has also been widely implemented on a voluntary basis by manufacturers of non‐laser light sources.

5 OPTICAL RADIATION CONTROL PRINCIPLES

Traditionally, radiation control principles have been summarized under the rubric of “time, distance, and shielding.” “Time” as a control principle refers to reducing risk by limiting the duration of exposure to the radiation. “Distance” refers to the reduction in risk associated with increasing the distance from the source. “Shielding” refers to the presence of an opaque or filtering medium between the source and the worker.

An additional control principle to consider is source optimization. Optimizing a source would include operating a source at the lowest power necessary to do the job, and, if possible, selecting sources with reduced spectral output in the blue‐light, UV‐A, UV‐B, and/or UV‐C regions if these wavelengths are not needed for the practical application.

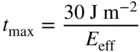

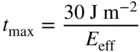

For actinic UV radiation, the maximum permissible exposure time is (15)

(24)

Читать дальше