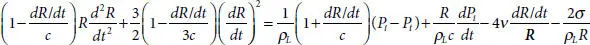

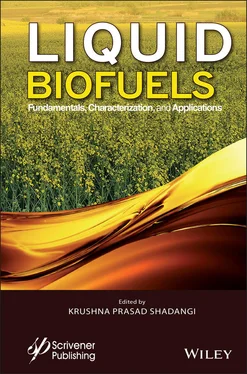

The model consists of four ODE (ordinary differential equations) and can be solved by taking boundary conditions based on the physical properties of liquids. The model starts with the radial motion equation for a bubble derived from the work of Keller and Miksis [105]:

(2.3)

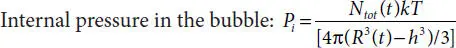

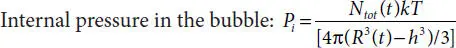

Internal pressure inside the bubble as well as bulk pressure in the liquid medium can be determined by using following equations [18]:

(2.4)

(2.5)

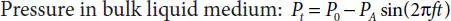

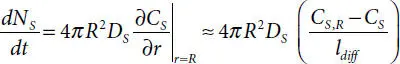

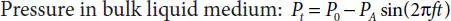

The ODE for determining the diffusive flux of solvent is as follows:

(2.6)

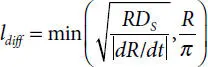

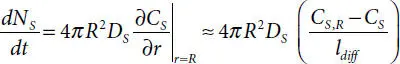

During the expansion of bubbles, the instantaneous diffusive penetration depth of solvent vapors into the cavitation bubbles can be predicted by:

(2.7)

As the compression and expansion of bubbles occurs, the heat conduction across the boundary walls of bubbles can be determined using following equations:

(2.8)

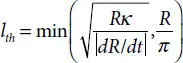

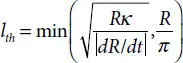

where, thermal diffusion length is expressed as:

(2.9)

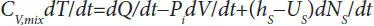

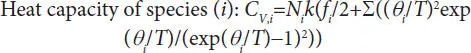

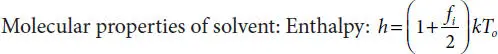

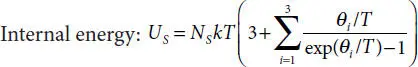

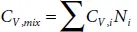

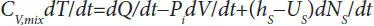

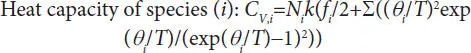

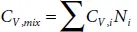

Finally, the overall energy balance can be carried out using equations given below:

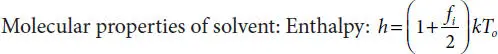

Mixture heat capacity:  ; where i = N 2/O 2/Solvent

; where i = N 2/O 2/Solvent

(2.10)

(2.11)

(2.12)

(2.13)

It was assumed that during the transient collapse of bubbles, the temperature and pressure reach the extreme values inside an exceptionally small volume of the bubble. The kinetics of dissociation reaction is much higher than bubble dynamics, and thus thermodynamic equilibrium is presumed inside the bubble [28, 29, 106].

Thus, the mathematical models presented herein are the most relevant and developed, repeatedly used in the estimation of cavitational effects in the reaction mixture. Moreover, more complex equations are needed to fully explain the intricate working of the cavitation zone, which considers non-linear behaviour of bubbles or clusters, non-uniform size of the bubbles or clusters, and heat and energy loss from or clusters during the growth of bubbles. The next section deals with the scale-up process of cavitational reactors based on computational fluid dynamics (CFD) approach.

2.5 Scale-Up of Cavitational Reactors

The ultrasound has been useful in resolving the mixing issues, challenges associated with clogging of particles for small-scale flow reactors. Similarly, large-scale batch reactors were designed to intensify mixing, increase reaction rates, and mass transfer in many chemical and biological processes [11, 107]. However, scaling up of conventional flow reactor in combination with ultrasound is a challenging task, and therefore, the application of large-scale industrial ultrasonic reactors is seldom seen. The main challenges are improving the energy efficiency of the reactor, the efficient transfer of ultrasound energy, and enhancing ultrasonic effects. The presence of complex flow patterns in a conventional flow reactor and non-uniformity of acoustic fields, scaling-up, is difficult. Cavitational reactors operate at two frequency ranges: low frequency (20-100kHz) and high frequency (>1 MHz). The low-frequency ultrasound helps to break up agglomerates in solid particles by shear forces induced by the collapse of cavitation bubbles. In contrast, the high-frequency ultrasound helps to prevent clogging due to the centering of particles in flow channels. Since the high-frequency ultrasound operates at a power level below the cavitation threshold, the cavitation effects are not observed, and effects such as acoustic streaming are observed [108]. Thus, to scale up a cavitational reactor, benefits of both low-frequency and high-frequency ultrasound to retain the advantages of micro- and mili-fluidic-reactor, and to control the acoustic pressure distribution across the scales is necessary.

Over the last two decades, two strategies have been developed to scale-up cavitational reactors. The first approach is to increase the characteristic size of the channel and the second one by operating several identical units in parallel or series. The characterization of primary and secondary effects of the ultrasound across the scale is important, and the main parameter to be controlled across reactor scales is the acoustic pressure field distribution in the liquid media. Verhaagane et al. [109] scaled up micro-reactor with increasing efficiency and reproducibility using the numbering up strategy and overserved the cavitation phenomena. Jamshid et al. [110] have used channel characteristics approach to scale-up cavitational reactors and used numerical simulation to obtain acoustic pressure distribution through the reactor. A combination of both the scale-up approach has also been studied by many researchers [107, 108, 111].

However, the scale-up of the cavitational reactor also depends on the understanding of the mechanism of ultrasound and efficient coupling between the ultrasonic device and the reactor. Currently, numerical method to quantify thermal or viscus loss due to cavitation is done by COMSOL simulations to connect and optimize the vibration response of solid materials, dynamic behavior of piezoelectric materials, structure vibrations and its connection to the surrounding fluid, both outside and inside of the closed volumes in the reactor. Further, modification of the numerical model for nonlinear response caused by cavitation can also be done in the software and thus COMSOL offers a powerful tool for scaling-up cavitational reactor efficiently. Figure 2.3the graphical illustration of acoustic pressure field variation across the reactor configuration by the COMOSOL.

Johansson et al. [111] reported the design of a scalable cavitational reactor using COMSOL. Delacour et al. [108] also successfully demonstrated the scale-up of cavitational reactor using COMSOL multiphasic. They highlighted the importance of developing experimental and numerical characterization methods of the ultrasound and cavitation effect for the design of scaled-up ultrasonic milli reactors. Bashir et al. [112] have reported computational fluid dynamics (CFD) tool to optimize the geometry of ultrasound reactors as given in Figure 2.4. The authors have used three parameters viz., the location of cavity inception, the pressure recovery rate, and the cavity growth time for optimization of venturi for cavitation application.

Читать дальше

; where i = N 2/O 2/Solvent

; where i = N 2/O 2/Solvent