Former editions:

1st edition September 1993 by S. Probert, S. Forrester-Coles

1st main revision September 1998 (general update)

2nd main revision October 2002 (general update) by A. Löfgren

small revision January 2003(small revision/update of integrity testing sections) by A. Löfgren

3rd main revision April 2007 (update in general and regarding the revised FDA guidance)

by E. Dewhurst

4th main revision Nov. 2011/March 2012 (general update, Media Fills, SIP, implementation of

rotary machine type 4010) by K. Downey, M. Haerer, S. Marguiller, P. Åkerman

5th corrected version December 2016

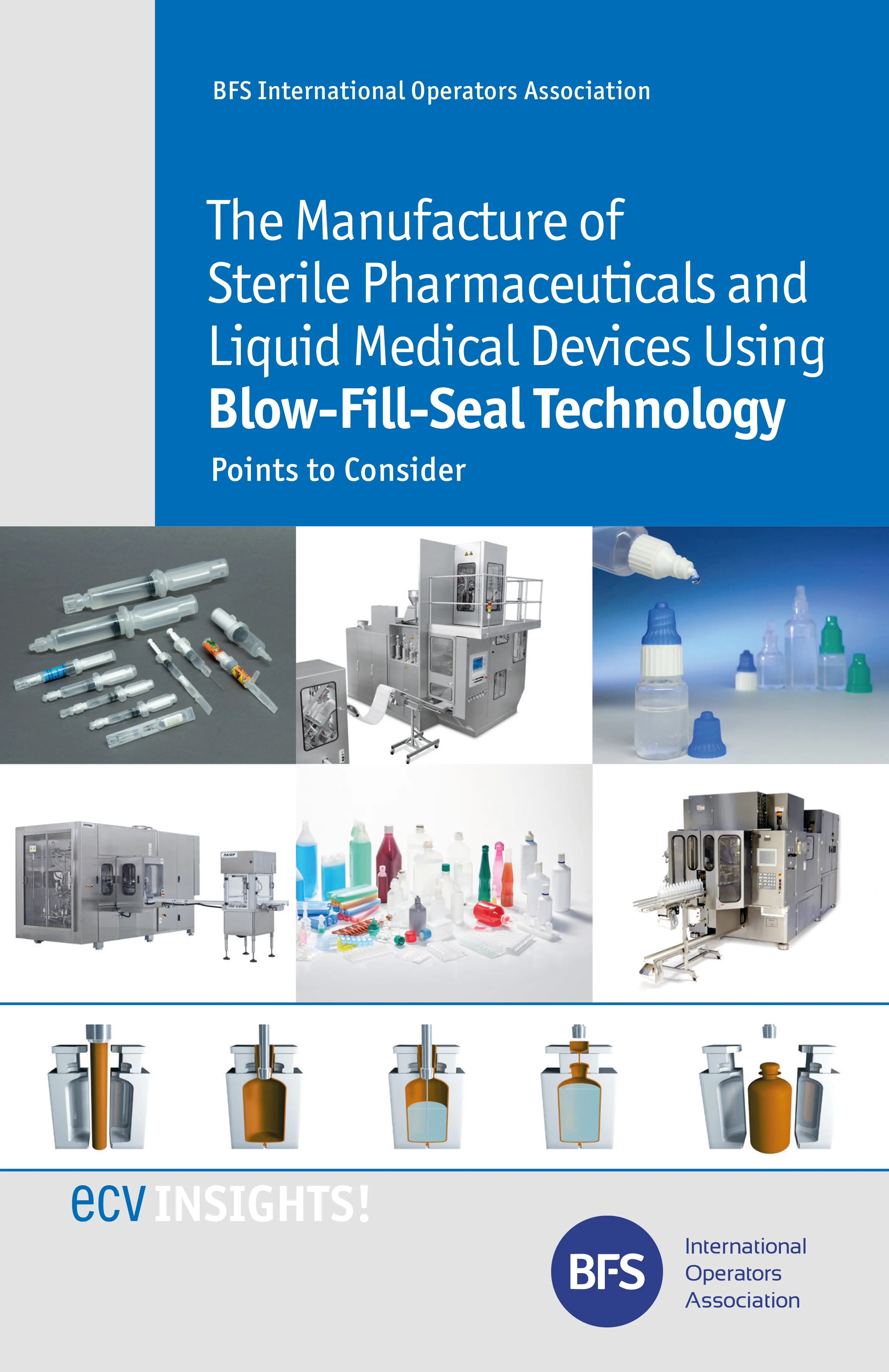

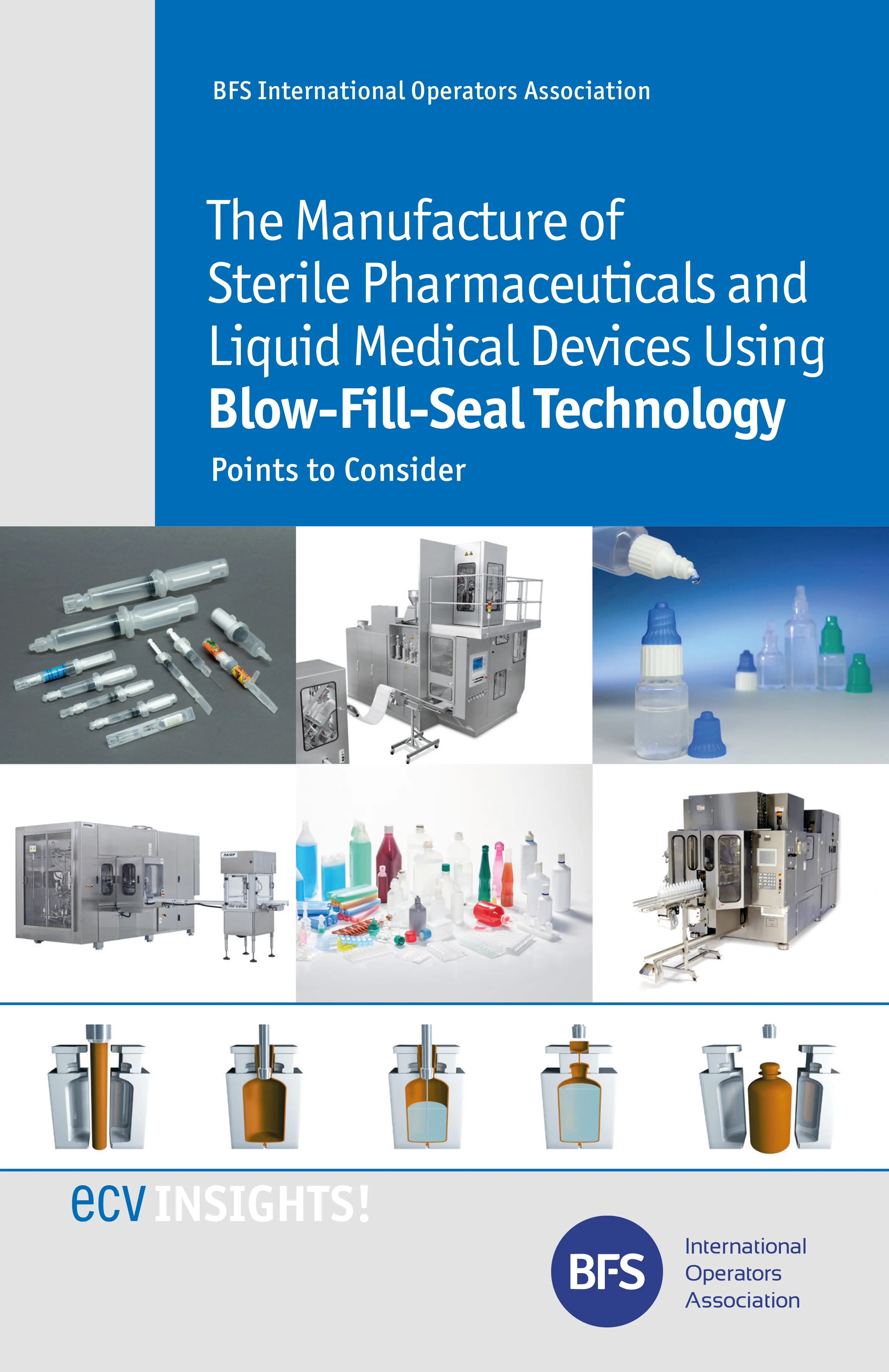

The pictures on the front cover are sponsored by Brevetti Angela, Rommelag and Weiler Engineering.

Bibliographic data available from the German National Library

The German Library catalogs this publication in the German National Bibliography; detailed bibliographic information can be found on the internet website: http://dnb.ddb.de.

The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to Consider

ISBN 978-3-87193-443-8

© 2017 ECV · Editio Cantor Verlag für Medizin und Naturwissenschaften GmbH, Aulendorf (Germany).

All rights, in particular those of duplication, distribution, and translation are reserved by BFS International Operators Association c/o Melitek A/S, DK-4840 Nørre Alslev, and the publisher without any limit in time. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise without the prior written permission of the publisher. The absence of the symbol ® after any name does not imply that this name is not under trademark protection.

ECV · Editio Cantor Verlag on the internet www.ecv.de

Typesetting: Reemers Publishing Services GmbH, Krefeld

Printing: HOLZMANN DRUCK GMBH & CO. KG, Bad Wörishofen

Contents

Disclaimer 7

1. INTRODUCTION 9

2. OBJECTIVE 11

3. BFS PROCESS OUTLINE 12

3.1 Shuttle Type Machines 12

3.2 Rotary Filling Machines 14

3.3 Additional Applications 16

4. ADVANTAGES & CHALLENGES OF BLOW-FILL-SEAL TECHNOLOGY 18

4.1 Advantages 18

4.2 Challenges 19

5. DESIGN 21

5.1 Product Design 21

5.1.1 Aseptic processing versus terminal sterilisation 21

5.1.2 Terminal sterilisation 21

5.1.3 Polymer 22

5.1.4 Container design 23

5.1.5 Secondary packaging 24

5.2 Equipment Design 25

5.2.1 General 25

5.2.2 Control of critical zone environment 26

5.2.3 Air shower design (shuttle type machines) 27

5.2.4 Product pathway 28

5.2.5 Mould design 28

5.2.6 Deflashing 29

5.2.7 Equipment Monitoring 29

5.2.8 Container closure system leak detection 30

5.3 Facility Design 31

5.3.1 Aseptic Processing Area (APA) 31

5.3.2 Support areas 34

5.3.3 Polymer storage and distribution 34

5.3.4 Utilities 35

6. QUALIFICATION AND VALIDATION 36

6.1 PRODUCT VALIDATION 36

6.1.1 Container/Closure integrity testing 36

6.1.2 Process capability 36

6.2 Equipment Validation 37

6.2.1 Extruder 37

6.2.2 Air Flow 38

6.2.3 Clean in Place (CIP) of the product pathway 38

6.2.4 Sterilisation in Place (SIP) of the product pathway 38

6.2.5 Process simulation (media fill) for aseptic filling lines 40

6.2.6 Moulding and filling system 44

6.2.7 Downstream process 44

6.2.8 Controls 44

6.2.9 Filtration 45

6.3 Facility Validation 45

7. OPERATION 46

7.1 Process Operation 46

7.1.1 In-process controls 46

7.1.2 Start-up procedures 47

7.1.3 Interventions 47

7.1.4 Environmental monitoring 48

7.2 Equipment Operation 51

7.2.1 Sanitisation of “critical” surfaces 51

7.2.2 Equipment cleaning 51

7.2.3 Cooling systems 51

7.2.4 Extruder control 51

7.2.5 Maintenance 52

7.3 Facility Operation 52

7.3.1 Gowning 52

7.3.2 Polymer handling 53

7.3.3 Use of regrind polymer material 53

7.3.4 Training 53

8. RISK ASSESSMENT 55

8.1 Product contamination 55

8.2 Other product quality attributes 57

APPENDIX 59

GLOSSARY 60

GUIDANCE REFERENCES 62

GENERAL REFERENCES 63

Disclaimer

This document was produced and is disseminated by the Pharmaceutical Blow-Fill-Seal International Operators Association (the “Association”) as a service of the Association solely for the convenience of its members. These ‘Points to Consider’ are an effort to provide a compilation of current Blow-Fill-Seal (“BFS”) manufacturing operations and practices. In producing this document, the Association has attempted to reflect accurately the current state of BFS manufacturing operations on a worldwide basis. However, the Association makes no claim whatsoever regarding these ‘Points to Consider’ to any user of these ‘Points to Consider’, including without limitation, any claim that the document:

– contains no errors

– covers all actual or potential aspects of BFS operations

– is in all instances completely up to date in its description or outline of current practice

– represent the unanimous [or consensus] opinion of the BFS industry or the Association members

– reflects the requirements of all applicable laws

All use of these ‘Points to Consider’ shall be at the user’s sole risk.

This document, and the procedures contained in the ‘Points to Consider’, has not been reviewed by, nor have they been endorsed by, filed or registered with, any governmental agency having jurisdiction over these matters. This document do not create any rights for, or confer any rights upon, any person, nor do they operate to bind the international and national authorities (FDA, European Commission, any other federal, state or local regulatory agency), or the public, in any manner. Where these ‘Points to Consider’ reiterate a requirement imposed by statute or regulation, the requirement’s having the force and effect of law is not changed or affected in any way by virtue of its inclusion in this document, nor does such inclusion give these ‘Points to Consider’ the force of law.

The mention in this document of commercial products, their sources, or their use in connection with matters described in the ‘Points to Consider’ is not, and is not to be construed as, either an actual or implied endorsement of such products by the Association.

The Association shall not be liable for, and disclaims all liability for, any and all losses, costs or damages, however arising, whether direct or indirect, incidental, consequential, punitive or exemplary, incurred as a result of or in connection with any person’s following, or failing to follow, these ‘Points to Consider’.

The BFS process is a technical one and appropriate and adequately trained expert personnel must be employed at each stage of the BFS process.

1. INTRODUCTION

Blow-Fill-Seal (BFS) technology has been used for pharmaceutical and liquid medical device manufacturing since the 1970s. This processing technology has become accepted worldwide for both aseptic and terminally sterilised liquid products and is currently used in more than 50 countries throughout the world.

Читать дальше