3School of Energy Science and Engineering, Vidyasirimedhi Institute of Science and Technology (VISTEC), Payupnai, Wangchan, Rayong, Thailand

Abstract

This chapter will focus on the development of bio-based polymers such as polyamides (PA), polylactide (PLA), and polyhydroxyalkanoates (PHAs) produced from renewable resources. Nylon TMplastic is a kind of PA is a long chain fiber-forming recalcitrant and biodegradable and degradable polymer with diverse applications. Polylactic acid (PLA) is biodegradable aliphatic polyester derived from a naturally occurring organic acid (lactic acid). On the other hand, PHAs are the high molecular weight biodegradable polyesters synthesized by a wide array of microbes. However, they have an undesirable influence on the environment and substantially impact waste deposition and utilization. This chapter will emphasize the application and microbial degradability of these three kinds (PLA, PHA, and PA) of plastics.

Keywords :Degradation, polyamides microbes, polylactide, polyhydroxyalkanoates

Research and development in the field of materials science over the past two decades have dramatically increased the production of synthetic or bio-based polymers [1, 2]. Plastics are usually hard to decompose but marginally affected by exposure to natural conditions such as sunlight, heat, oxygen, or biological and hydrolytic processes. Long-term undesirable accumulation of plastics in soil and water imposes a significant threat to the environment, and it can take from a year to decades for them to decompose [1–3]. Rising demands of plastics in both commercial and domestic sectors make it challenging for its proper disposal [4]. Although, several methods such as modification of molecular structure, side chain, reinforcement, and addition of some side-chain in plastics were developed, aiming to plastic waste management [5]. However, these modifications affect its molecular chain, morphology, chemistry, degree of polymerization, thermal properties, and hydrolytic behaviors [5]. There are widely used synthetic or bio-based polymers like polyamide (PA), polylactic acid (PLA), and polyhydroxyalkanoates (PHAs) with low melting temperature and degraded faster than other high-performance polymers such as PBO (polybenzoxazole), PBI (polybenzimidazole), and PI (polyimide) [1–3]. PAs were considered to be exciting materials since 1930 due to its molecular structure (-CONH-). However, its fibers are resistant to biodegradation because of chain symmetry [6]. But nylon degradation can occur after side-chain modification; scission of the chain, as well as a low oligomer, can be degraded [6, 7]. Hashimoto and Naoka et al . reported about especially nylon 4 degrade under the soil in the presence of marine bacteria [7, 8]. Recently, Kaneko et al . (2014) reported itaconic acid-based heterocyclic PAs, which are environmentally degradable under soil and water in the presence of UV light [8]. Naturally occurring polymers, bio-derived plastics, and synthetic bio-based plastics from renewable resources are the existing bases for establishing a sustainable society [9, 10]. Replacing bio-sourced materials over the existing fossil-fuel-based plastics are the prime focus of recent research [9]. However, different microbial-derived well-known bio-polyester like PHAs and PLA has low melting temperature tensile strength, and its biodegradable nature can replace the petrochemical-based plastics. There are various methods for the degradation of the polymer.

1 1. Thermal degradation

2 2. Photo-oxidative degradation

3 3. Hydrolytic degradation

4 4. Mechanochemical degradation

5 5. Soil degradation

6 6. Biodegradation

Some of the factors that affect the degradation process such as

- Color changes

- Scission of the backbone

- Modification of one or more end-groups

- Disruption of a side chain

- Mechanical

- Photo/thermal

- Chemical

- Cracking and charring (weight loss)

- The effect of light, heat, air, and moisture reflects the polymer structure.

Biodegradation can be defined as the breaking down material when exposed to microbes such as bacteria, fungi, actinobacteria, or other biological means anaerobically or aerobically [2]. Moreover, polymers biodegradation is possible by different enzymatic and non-enzymatic hydrolysis without thermal oxidation, radiolysis, or photolysis [3]. Alternatives to the existing fossil fuel and other non-renewable sources are the prime focus of today now. This chapter describes the broad spectrum of bioavailability, biosynthesis and biodegradability of PA, PLA, and PHAs.

Definition

Nylon TMis a necessary term that represents an important class of PAs. PA with amide linkage exhibits high thermomechanical properties and higher softening temperature because of hydrogen bonding, which provides chain symmetry [9]. Presence of amide linkages in PA used as engineering thermoplastics as a film or fibers form. Nylon 6-6 is the most commercialized polymer widely used because of its high thermomechanical properties [11].

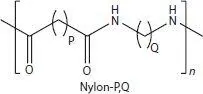

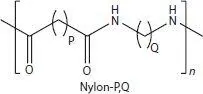

The Nylon-P,Q ( Figure 4.1) refers to the number of carbon atom used in the monomeric chain, which was commercialized as Nylon TMis petroleum-derived nylon-6,6 and nylon-6 [6, 9]. PAs are generally a non-biodegradable polymer, although amide linkages were degraded by disrupting the hydrogen bonding [6]. Petroleum-based polymers are posing a significant threat to the environment and its sustainability. Bio-based materials can be alternatives to these petroleum-based polymers. Bio-derived PAs are very much sustainable. The establishment of these sustainable bio-based PAs reduces the use of petroleum-based polymers and reduces ecological problems. PAs, on the other hand, are one of the most consumed polymers as it consumed globally around 7.4 million tons/ annum for the year 2016. Total consumption of PA in 2016 is divided into two parts: PA fibers and film shares 55% globally but 45% share textiles industries used as seats, carpet, sportswear, and different clothes. Some of the bio based, especially fatty acids in vegetable oils, are the source of various monomers to achieve PA.

Figure 4.1 Structures of polyamide with trade name NylonTM (Nylon-P, Q).

4.2.1 Bioavailability and Production

Nondegradable polymers are one of the big issues and create lots of stress over the environment because of PA dumping. A sustainable polymer helps in reducing this stress over the environment. Variety of bio-PAs are derived from renewable raw materials such as PA 4,6; PA 4,4; PA 4,10; PA 4; PA 6,10; PA, 10,10; PA 10,12; and PA 11 [6, 9]. Five decades back, European company Arkema first developed Rilsan, which is 100% castor oil-based PA (PA-11) [6]. Many bio-based polymers were synthesized from castor oil-based with 60% sebacic acid, which exhibits superior performances than petroleum-derived PA 6 and PA 6,6. Nylon 4 is synthesized after ring-opening polymerization of 2-pyrrolidone [2, 5a, 7]. Recently, itaconic acid-based heterocyclic PA has been introduced environmentally degradable, which can reduce the burden of polymer waste [8].

4.2.2 Biodegradability of Polyamides

PAs containing amide linkage have strong hydrogen bonding that is less susceptible to the degradation, but some bacteria can attack their low molecular chain [6, 11, 12]. It should be kept in mind that according to IUPAC terminology, the biodegradable polymer is able to undergo chain scissions, resulting in a decrease in molar mass due to enzymatic process from the action of cells; however, in vitro activity of isolated enzymes cannot be considered as biological activity [12, 13]. Even though bio-based material is composed or derived in whole or natural products issued from the biomass, it does not mean that the material is biodegradable. Certain aliphatic PAs are susceptible to biodegradation by microorganisms (fungi or bacterium) [2]. Some of the thermophilic bacteria isolated from the soil favor the degradability of PA 12 and PA 66 in the culture medium [2]. Some of the white-rot fungal strains have these three kinds of enzyme which are able to degrade the nylon [5b, 12, 13]. Some of the marine bacteria degraded the PA 6 and PA 66, such as Bacillus sphericus , Vibrio furnisii and Brevundimonas vesicularis . The PA can be degraded due to the endogenous enzymatic hydrolysis of an amide linkage [3]. The 14C-labeled nylon-6,6 exposed to various enzyme solutions in vitro , but it was unaffected by some of the enzyme-like esterases, but it degraded after exposure of chymotrypsin, trypsin, and papain.

Читать дальше