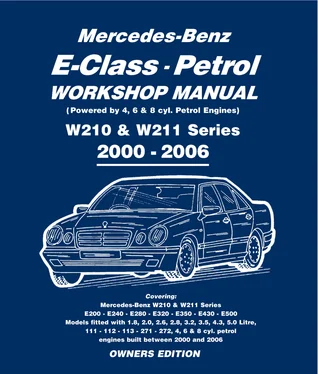

The V6 six-cylinder engine with 18 valves is fitted to models E240, E280 and E320. Most engines belong to the series "112", but "272" engines are fitted to model series W211. A V6 engine with 24 valves is fitted to models E350 (engine type "272"). Finally there is the V8 engine in the model range. Engine type "113" us used for both capacities.

The advantages of a multi-valve technology

One of the basic problems of a four stroke engine is the filling of the cylinders during the induction stroke with the necessary amount of the fuel/air mixture. The problem is made worse with increasing engine speed, as the opening period of the valves is shortened. Technicians refer to filling loss. To compensate the valve diameters are selected as large as possible so that more fuel/air mixture can enter, but the disadvantage is, of course, the larger diameter of the compression chamber.

This is the main reason for the introduction of the multi-valve technology. Four valve heads make up a larger opening area than two large valve heads and the size of the compression chamber can remain the same.

The advantages of the four valves can therefore be given as follows:

• Four valves enable larger opening diameters for inlet and exhaust gases. This helps the engine performance and the fuel consumption. This is one of the reasons that an engine with four valves per cylinder has a better consumption than a engine with two valves.

• Engines with four valves per cylinder have smaller valves and thereby less weight to be moved. A quicker response of the valve gear is therefore possible. One more advantage of this construction is that valve springs with a lower pressure are necessary to close the valves.

• Smaller valves are able to cool down quicker during the closing period.

• Engines with four valves per cylinder are also enable to obtain a higher compression ratio.

• The spark plugs can be centred in the compression chamber to provide the best possible igniting of the fuel/air mixture.

The vehicles covered in this manual are fitted with a six-speed manual transmission or an automatic transmission with five or seven speeds or a 4-Matic transmission.

The W210 and W211 series have a double wishbone front suspension with coil springs and telescopic shock absorbers and a stabiliser bar.

The so-called multi-link independent rear suspension comprises the rear axle carrier, provided with double-row angular ball bearings. The wheel carriers are guided by 5 specially located links, referred to as camber strut, pulling strut, pushing strut, track rod and spring links, the latter being the actual suspension arms. The hydraulic shock absorbers are fitted between the spring links and the body. A torsion bar is fitted to the spring links and the frame floor by means of a connecting link. The well-known level control system in other Mercedes Benz models is either fitted as standard or as an optional extra throughout the range.

Disc brakes on all four wheels, with dual-line brake system and brake servo is fitted. The handbrake acts on the rear wheels.

The rack and pinion steering with servo-assistance, introduced during the introduction of series W210 has been retained for series W211.

0.1. Vehicle Identification

The type identification plate is located at the R.H. side on the upper face of the radiator frame and contains the vehicle type, chassis number, permissible maximum weight and the permissible axle load on front and rear axle. The paint code is located in the plate opposite.

The chassis number can also be found in the engine compartment bulkhead. The first six numbers refer to the vehicle type, the 7 thnumber refers to the steering and the 8 thnumber to the transmission. The following six numbers are the actual serial number.

The engine number is stamped into the cylinder block on the side of the starter motor, immediately below the intake tube.

The code numbers and letters must always be quoted when parts are ordered. Copy the numbers on a piece of paper and take it to your parts supplier. You will save yourself and your parts department delays and will prevent you from ordering the wrong parts.

0.2. General Servicing Notes

The servicing and overhaul instructions in this Workshop Manual are laid out in an easy-to-follow step-by-step fashion and no difficulty should be encountered, lf the text and diagrams are followed carefully and methodically. The "Technical Data" sections form an important part of the repair procedures and should always be referred to during work on the vehicle.

In order that we can include as much data as possible, you will find that we do not generally repeat in the text the values already given under the technical data headings. Again, to make the best use of the space available, we do not repeat at each operation the more obvious steps necessary – we feel it to be far more helpful to concentrate on the difficult or awkward procedures in greater detail. However, we summarise below a few of the more important procedures and draw your attention to various points of general interest that apply to all operations.

Always use the torque settings given in the various main sections of the manual. These are grouped together in separate sub-sections for convenient reference.

Bolts and nuts should be assembled in a clean and very lightly oiled condition and faces and threads should always be inspected to make sure that they are free from damage burrs or scoring. DO NOT degrease bolts or nuts.

All joint washers, gaskets, tabs and lock washers, split pins and "O" rings must be replaced on assembly. Seals will, in the majority of cases, also need to be replaced, if the shaft and seal have been separated. Always lubricate the lip of the seal before assembly and take care that the seal lip is facing the correct direction.

References to the left-hand and right-hand sides are always to be taken as if the observer is at the rear of the vehicle, facing forwards, unless otherwise stated.

Always make sure that the vehicle is adequately supported, and on firm ground, before commencing any work on the underside of the car. A small jack or a make shift prop can be highly dangerous and proper axle stands are an essential requirement for your own safety.

Dirt, grease and mineral oil will rapidly destroy the seals of the hydraulic system and even the smallest amounts must be prevented from entering the system or coming into contact with the components. Use clean brake fluid or one of the proprietary cleaners to wash the hydraulic system parts. An acceptable alternative cleaner is methylated spirit, but if this is used, it should not be allowed to remain in contact with the rubber parts for longer than necessary. It is also important that all traces of the fluid should be removed from the system before final assembly.

Always use genuine manufacturer's spares and replacements for the best results.

Since the manufacturer uses metric units when building the cars it is recommended that, these are used for all precise units. Inch conversions are given in most cases but these are not necessarily precise conversions, being rounded off for the unimportant values.

Removal and installation instructions, in this Workshop Manual, cover the steps to take away or put back the unit or part in question. Other instructions, usually headed "Servicing", will cover the dismantling and repair of the unit once it has been stripped from the vehicle it is pointed out that the major instructions cover a complete overhaul of all parts but, obviously, this will not always be necessary and should not be carried out needlessly.

There are a number of variations in unit parts on the range of vehicles covered in this Workshop Manual. We strongly recommend that you take care to identify the precise model, and the year of manufacture, before obtaining any spares or replacement parts.

Читать дальше