Table 2.1 Analysis report.

| Distance |

Kp |

Ki |

Kd |

Settling time |

| Error 500 |

10 |

0.5 |

5 |

NIL |

| 500 |

0.22192 |

1.32339 |

0.12735 |

11 seconds |

| 1,000 |

0.93028 |

0.31099 |

0.75421 |

8 seconds |

| 1,500 |

0. 38281 |

0.19672 |

0.24252 |

9 seconds |

The MATLAB software has been analyzed for different values of reference. Kp, Ki, and Kd and settling time have monitored across each references ( Table 2.1).

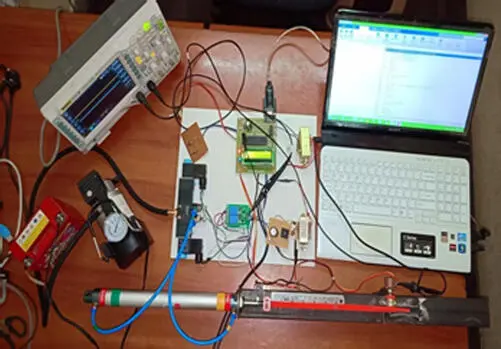

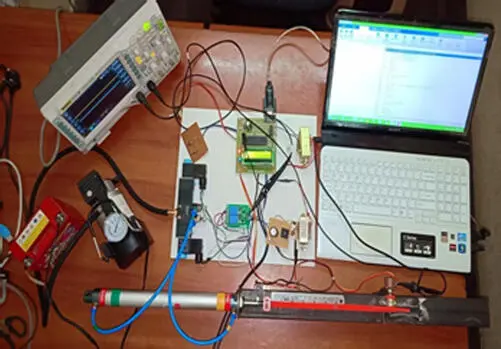

The displacement of the piston is measured and converted to digital signal and then given to the System. The FOPID using GA generates the most accurate value using successive iterations. This value is given to the controller, which moves the piston to that value. Thus, the position is controlled using FOPID controller. Figure 2.16shows the hardware setup of the position servo system.

Figure 2.16 Hardware setup of position servo system.

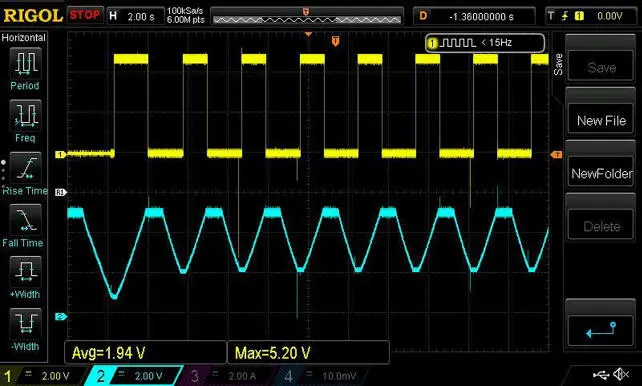

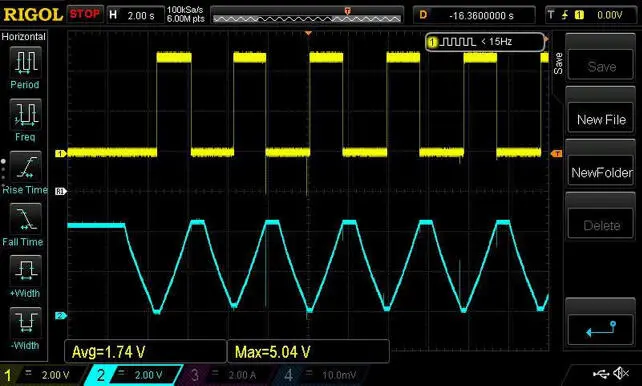

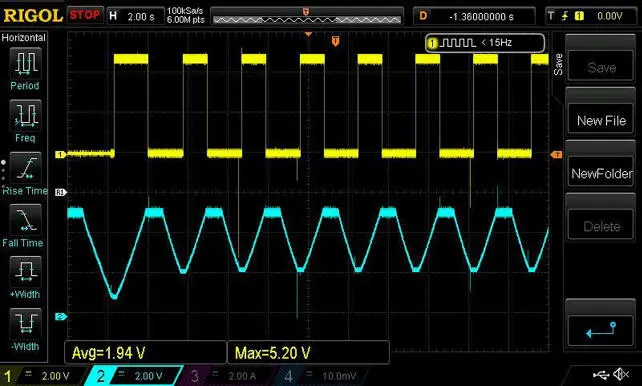

Figure 2.17illustrate the average output voltage of piston using hardware module.

Figure 2.17 CRO output waveform.

CRO output consist of average output voltage of piston based on displacement.

The displacement of the piston is not settled at a reference value. Hence, this CRO output waveform is considered as error. To rectify this, we use GA. Figure 2.18shows average output waveform of 500 reference (error).

Figure 2.18 CRO output waveform of 500 reference (Error).

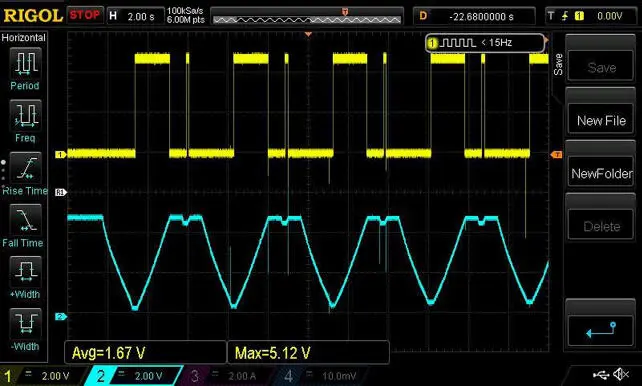

Figure 2.19a shows the average output waveform for reference value of 500 with GA.

Figure 2.19 (a) CRO output waveform of 500 reference.

When the reference value is set as 500 and the Kp, Ki, and Kd values are taken by execution of iterations in GA, then the error is minimized and the displacement is settled at the reference value. The Kp, Ki, and Kd values obtained by GA are 0.221923828125,1.323396901967211, and 0.12735267270242523.

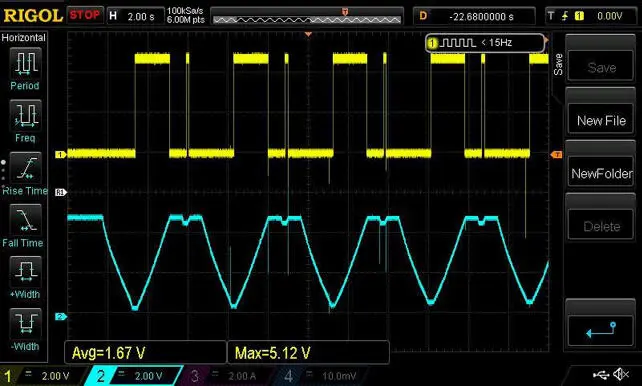

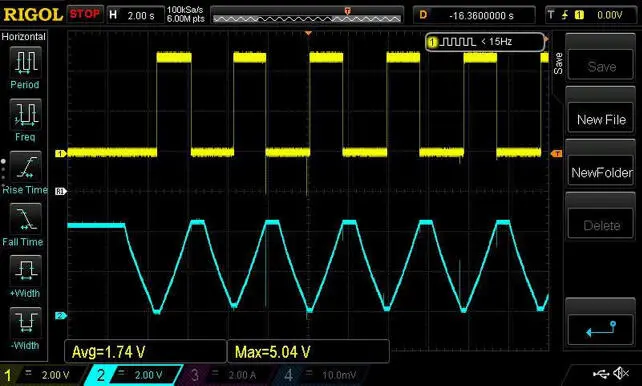

Figure 2.19 (b)CRO output waveform of 1,500 reference.

When the reference value is set as 1,500 and the Kp, Ki, and Kd values are taken by execution of iterations in GA, then the error is minimized and the displacement is settled at the reference value. The Kp, Ki, and Kd values obtained by GA are 0. 38281, 0.19672, and 0.24252. Figure 2.19 bshows the average output waveform for reference value of 1500 with GA.

Resembling the fractional-order dynamics of gas flow, the pneumatic system also has similar dynamics. Based on the analysis from the literature survey, it has been found that the fractional-order controllers provide enhanced control for the systems that possess fractional-order dynamics. Hence, in this work, FOPID controllers are used to control pneumatic position servo system. One of the challenging issues while applying FOPID controller is the tuning of parameters. In this paper, MMGA method based on Pareto rank is proposed for tuning FOPID parameters. It is evident from the results that FOPID is exceeding IPID in terms of greater accuracy and less energy consumption. It is worthwhile to point out that the dynamic behavior of FOPID controllers are superior to PID controllers. The efficacy of the proposed method is also exhibited by comparing its performance with six methods proposed in the literature. The pneumatic position control system using FOPID gives the best performance than IPID controller. GA is used to find the optimized values of FOPID controller. This paper discussed about the implementation of optimized FOPID controller using GA to find the maximum fitness solution. Simulation results in MATLAB and hardware results from PIC microcontroller validated the proposed algorithm thereby showing the superior performance of FOPID over IPID controller in a pneumatic position servo system.

1. Ren, H.-P., Wang, X., Fan, J.-T., Kaynak, O., Adaptive backstepping Control of a Pneumatic System with unknown Model Parameters and Control Direction. IEEE Access , 7, 64471–64482, 2019.

2. Salim, S.S.N., Rahmat, M.F., Faudzi, M., Ismail, Z.H., Sunar, N., Position control of pneumatic actuator using self-regulation nonlinear PID. Math. Probl. Eng ., 2014, Article ID 957041, 12, 181–195, 2014.

3. Gong, Q.H., Control of pneumatic servo system based on neural network PID algorithm. Appl. Mech. Mater ., 457, 1344–1347, 2014.

4. Ren, H.-P. and Chao, H., Experimental tracking control for pneumatic system. IECON 2013-39th Annual Conference of the IEEE Industrial Electronics Society , pp. 4126–4130, 2013.

5. Taheri, B., Case, D., Richer, E., Force and stiffness backstepping-sliding mode controller for pneumatic cylinders. IEEE/ASME Trans. Mechatron ., 19, 6, 1799–1809, 2014.

6. Garmsiri, N. and Sepehri, N., Emotional learning based position control of pneumatic actuators. Intell. Autom. Soft Comput ., 20, 3, 433–450, 2014.

7. Essa, ME-SM., Aboelela, M.A.S., Hassan, M.A.M., Abdraboo, S.M., Fractional Order Fuzzy Logic Position and Force Control of Experimental Electro-Hydraulic Servo System, in: 2019 8th International Conference on Modern Circuits and Systems Technologies (MOCAST) , IEEE, pp. 1–4, 2019.

8. Ren, H.-P., Wang, X., Fan, J.-T., Kaynak, O., Fractional order sliding mode control of a pneumatic position servo system. J. Franklin Inst ., 356, 12, 6160– 6174, 2019.

9. Al-Dhaifallah, M., Kanagaraj, N., Nisar, K.S., Fuzzy fractional-order PID controller for fractional model of pneumatic pressure system. Math. Probl. Eng ., 2018, 9, 2018.

10. Liu, L. and Zhang, S., Robust fractional-order PID controller tuning based on Bode’s optimal loop shaping. Complexity , 2018, 14, 2018.

11. Dastjerdi, A.A., Saikumar, N., HosseinNia, S.H., Tuning guidelines for fractional order PID controllers: Rules of thumb. Mechatronics , 56, 26–36, 2018.

12. Kumar, P., Chatterjee, S., Shah, D., Saha, U.K., Chatterjee, S., On comparison of tuning method of FOPID controller for controlling field controlled DC servo motor. Cogent Eng ., 1, 1357875, 2017.

13. Machado, J.A.T., Optimal tuning of fractional controllers using genetic algorithms. Nonlinear Dyn ., 1–2, 447–452, 2010.

14. Ren, H.-P., Fan, J.-T., Kaynak, O., Optimal design of a fractional-order proportional-integer-differential controller for a pneumatic position servo system. IEEE Trans. Ind. Electron ., 66, 8, 6220–6229, 2018.

Читать дальше