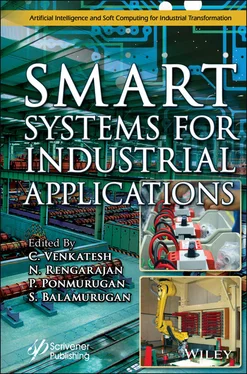

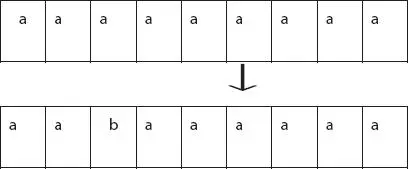

Mutation is the process in which the values of gene are altered. The gene to be mutated are curtained by the mutation parameter. Mutation results in the generation of novel features in the offspring. Occasionally, the feature may lead the offspring to be poor or superior. Figure 2.5exhibits the mutation phase.

Figure 2.5 Mutation.

2.5.2 GA Parameter Tuning

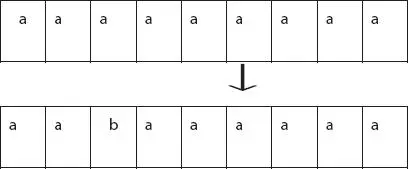

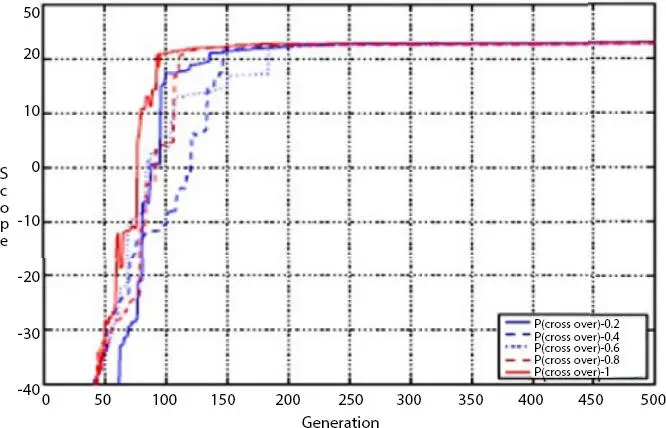

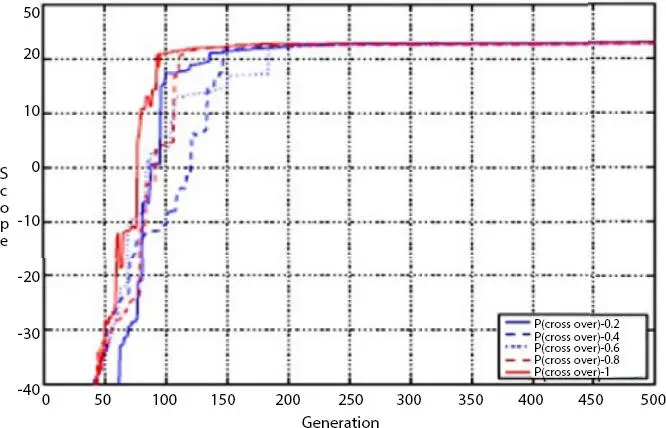

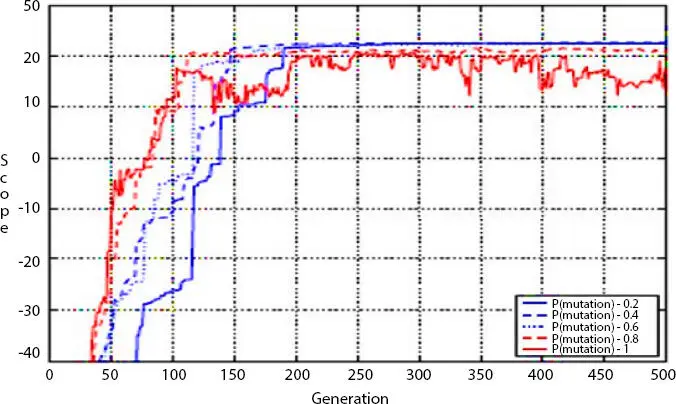

GA execution involves tuning of three parameters, namely, crossover probability, mutation probability, and the number of optimal generations. The population evolution depends on crossover and mutation whereas number of generations are chosen such that the solution is an optimal one. Studies had been carried out with crossover probability ranging between 0.2 and 0.1. Its corresponding mutation probability is taken as 0.4, and hence, maximum fitness is reached. Figures 2.6and 2.7show the results of GA tuning.

Figure 2.6 Fitness with crossover probabilities.

Figure 2.7 Fitness with mutation probabilities.

2.6 Simulation Results and Discussion

2.6.1 MATLAB Genetic Algorithm Tool Box

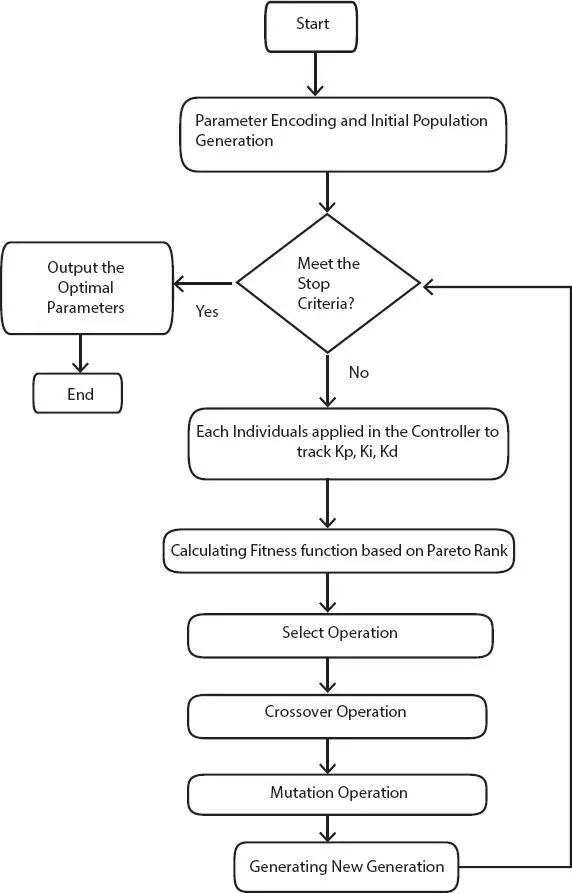

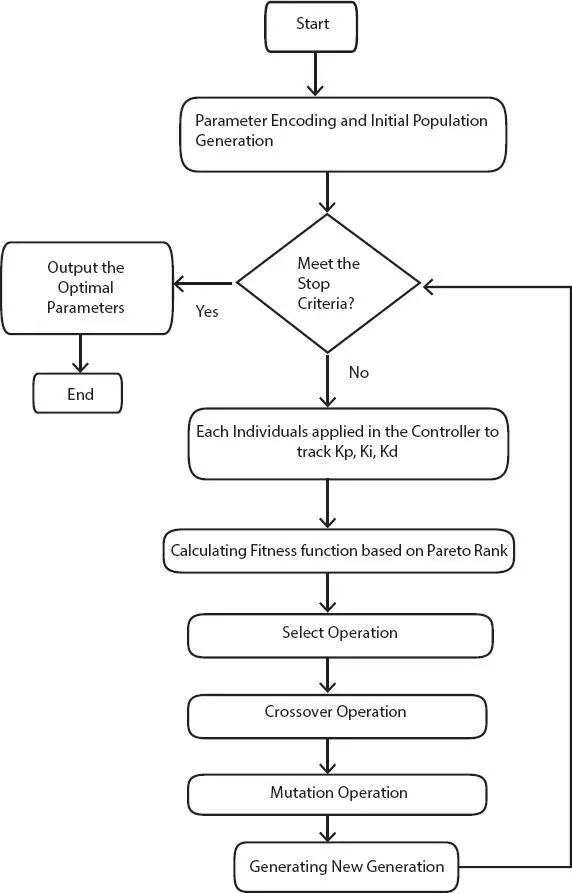

MPLAB established by Microchip Technology is an exclusive integrated software setting for the improvement of applications in PIC microcontrollers. MPLABX is the state-of-the art edition of MPLAB, developed on the Net Beans platform. They support project management, code editing, debugging, and programming of Microchip 8-bit PIC and AVR (including ATMEGA) microcontrollers, 16-bit PIC24 and dsPIC microcontrollers, as well as 32-bit SAM (ARM) and PIC32 (MIPS) microcontroller ( Figure 2.8).

GA finds its extensive application in control engineering. MATLAB has an integrated GA toolbox which helps the control engineers to apply genetic search methods effectively. Figure 2.9is the GA toolbox in finding solution to control system design problems.

A high level matrix language containing M file with MATLAB code is developed to set the five parameters for position control of the piston. The software is analyzed for different values of reference input and the characteristics graph are taken down with the gain of Kp, Ki, and Kd.

Figure 2.8 Flowchart of genetic algorithm.

2.6.2.1 Reference = 500 (Error)

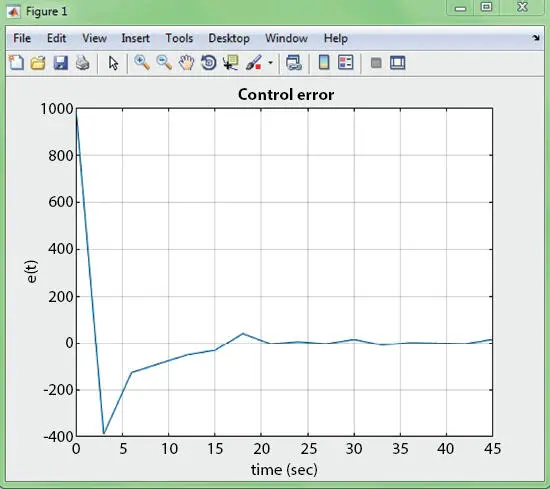

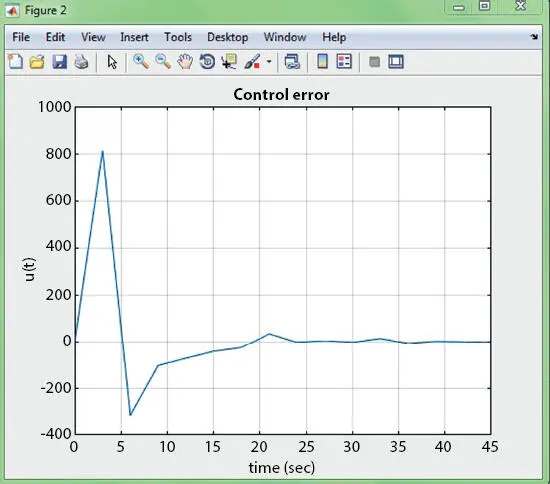

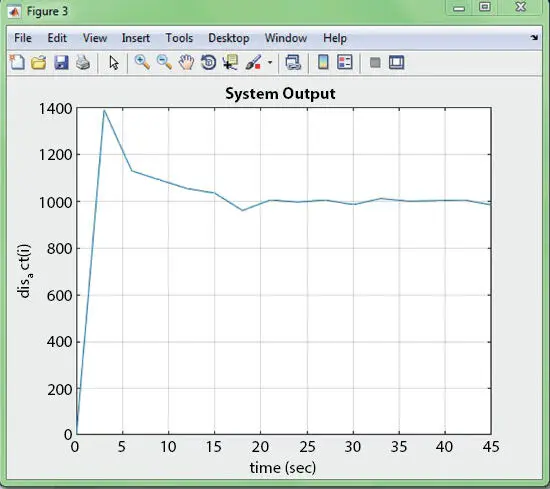

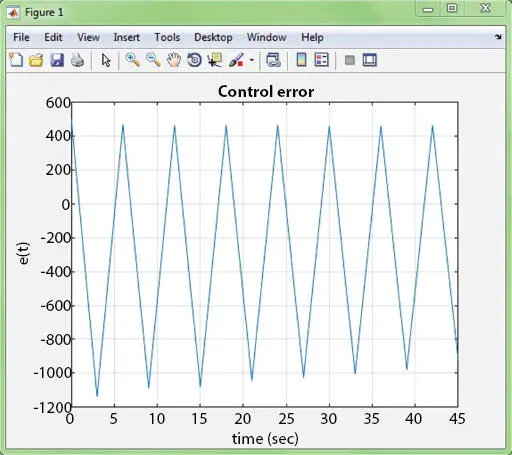

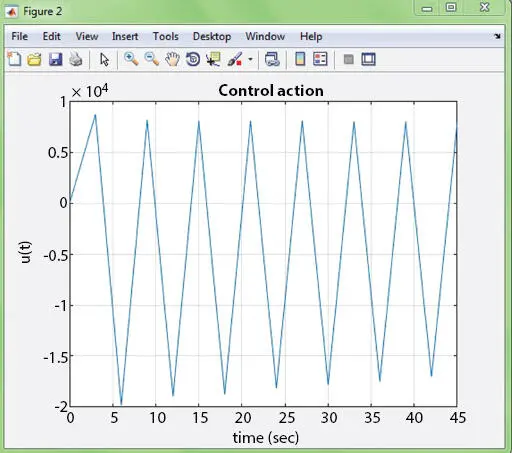

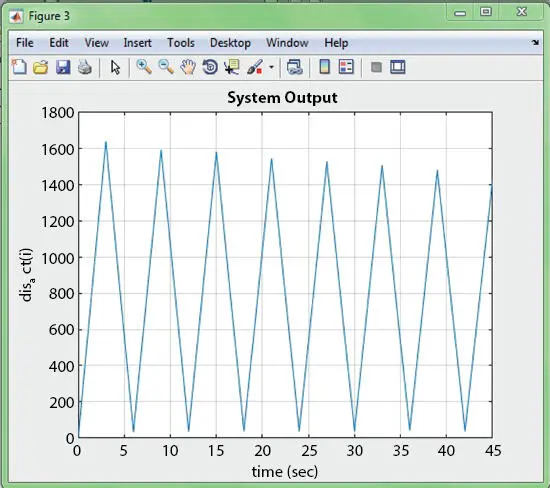

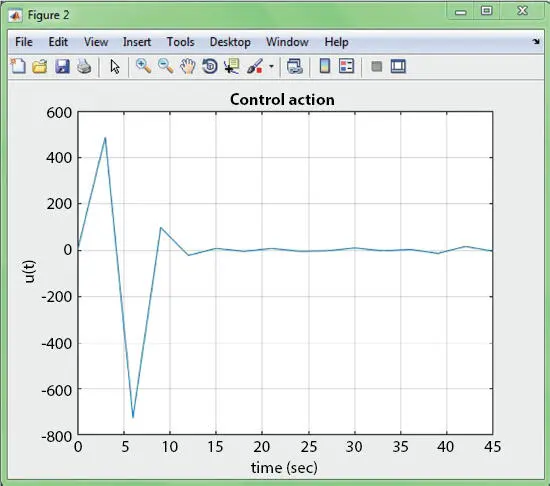

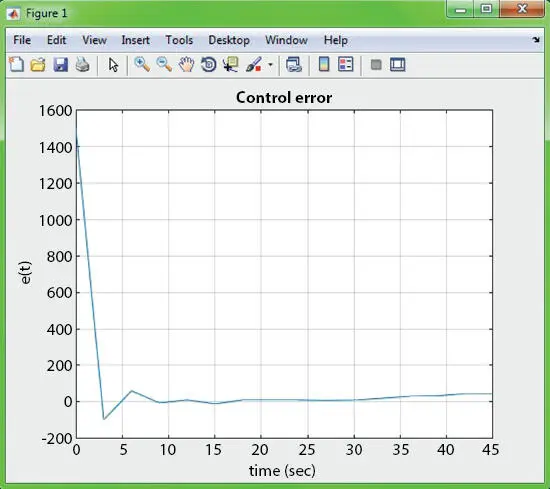

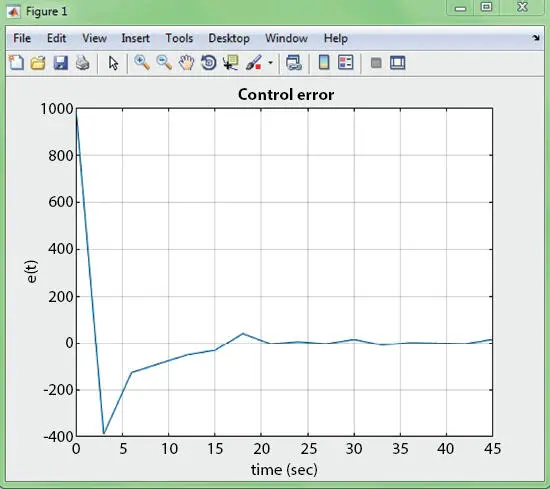

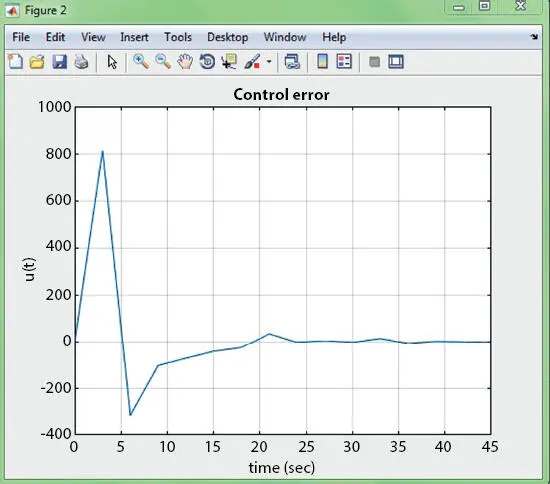

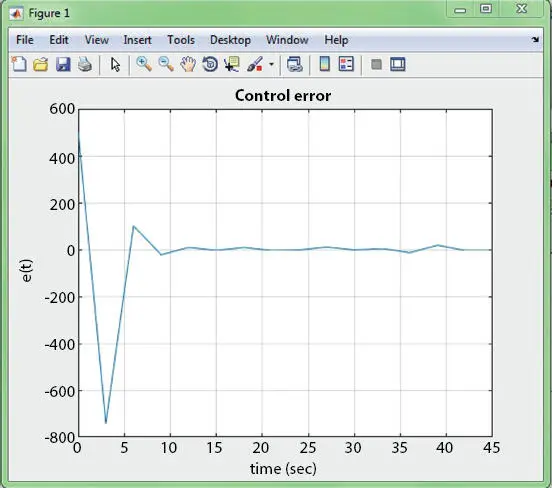

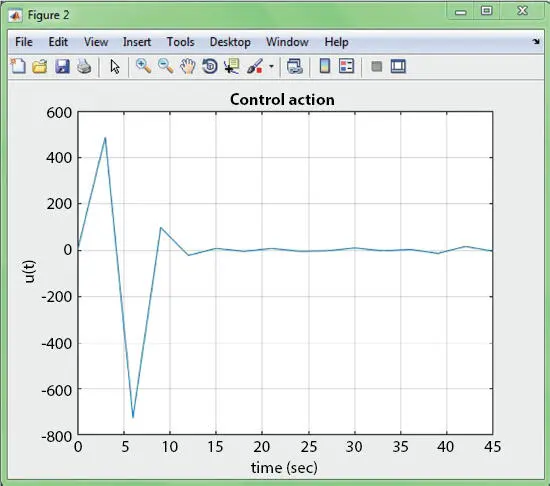

When the reference value is set as 500 and the Kp, Ki, and Kd values are taken manually (10, 0.5, and 3) without using GA, then the output will be coming as follows. Figures 2.10, 2.11and 2.12shows the control error, control action and system output.

Figure 2.9 Genetic algorithm tool box.

Figure 2.10 Control error.

Figure 2.11 Control action.

Figure 2.12 System output.

Figures 2.13 a, band c shows the piston displacement at a reference = 500 (error) using Kp = 10, Ki = 0.5 and Kd = 3 without GA.

Figure 2.13 (a) Control error for reference value 500 (error).

Figure 2.13 (b)Control action for reference value 500 (error).

Figure 2.13 (c)System output for reference value 500 (error).

Here, the displacement of the piston is not settled at a reference value. Hence, this output is considered as error. To rectify this, we use GA.

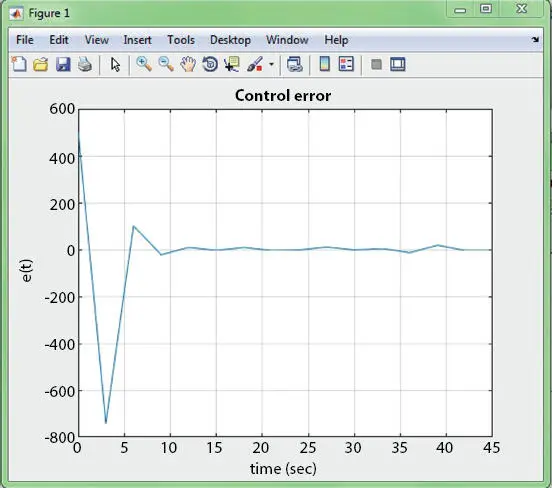

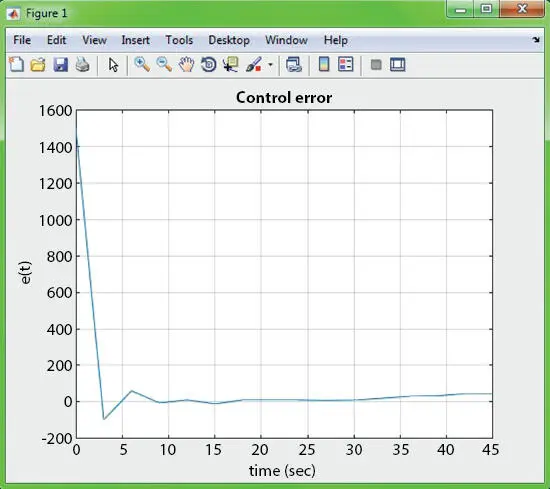

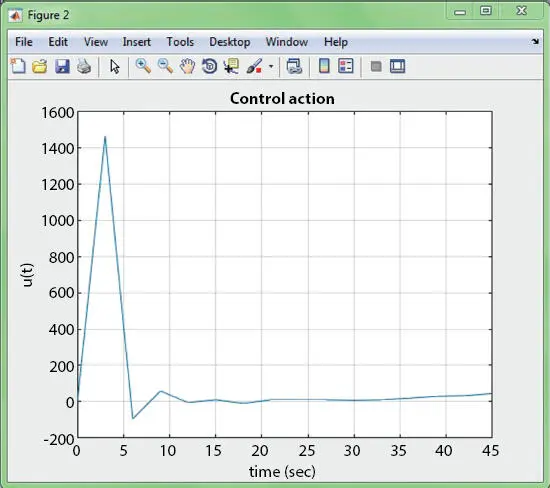

When the reference value is set as 500 and the Kp, Ki, and Kd values are taken by execution of iterations in GA, then the error is minimized and the displacement is settled at the reference value in the output as shown in Figures 2.14a, band c.

The Kp, Ki, and Kd values obtained by GA are 0.221923828125,1.32339 6901967211, and 0.12735267270242523.

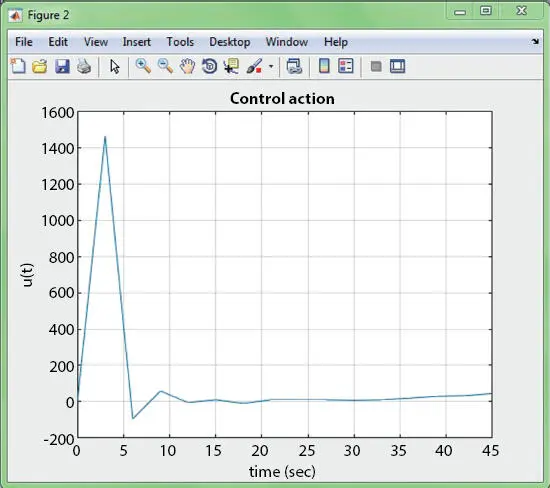

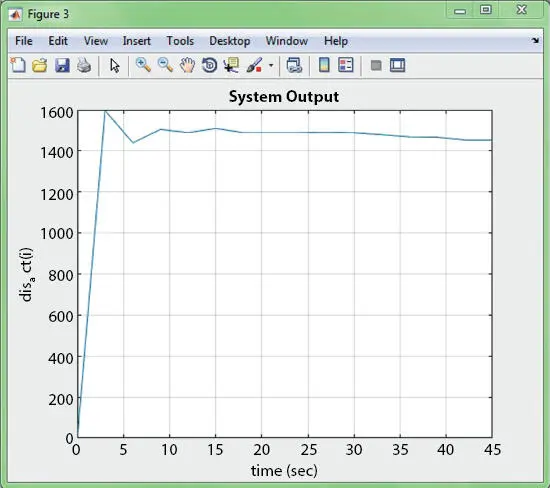

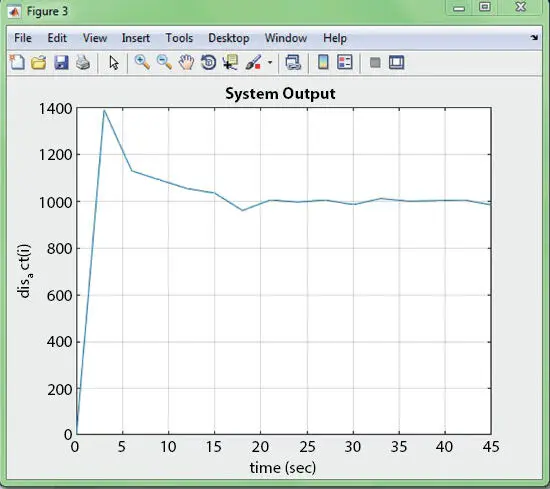

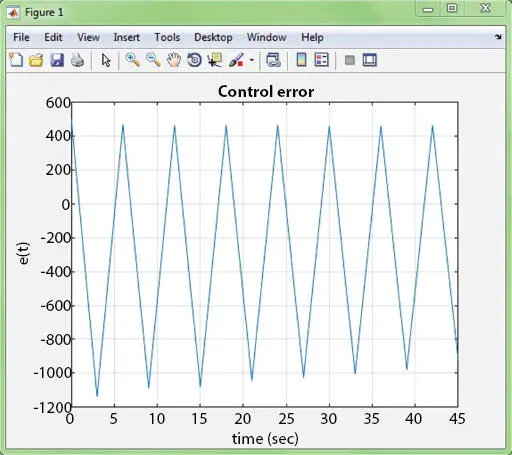

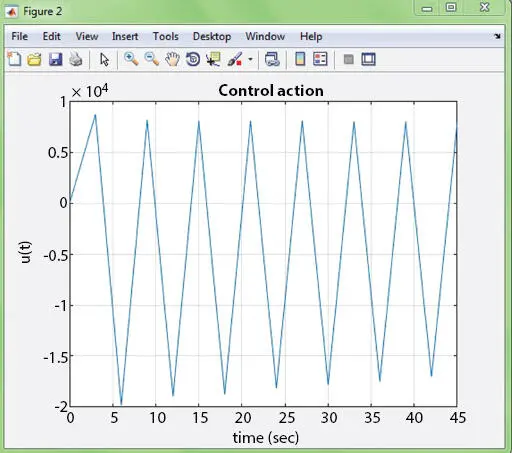

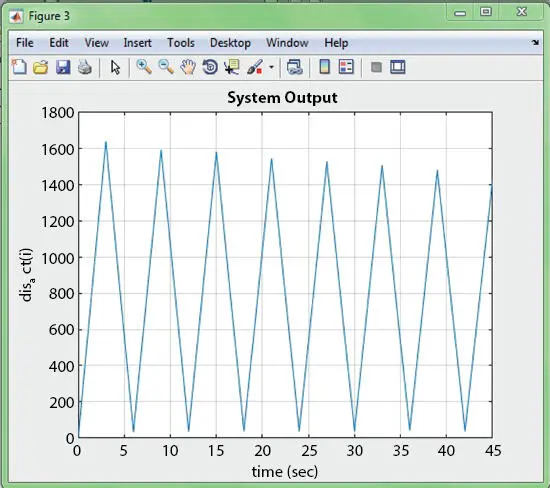

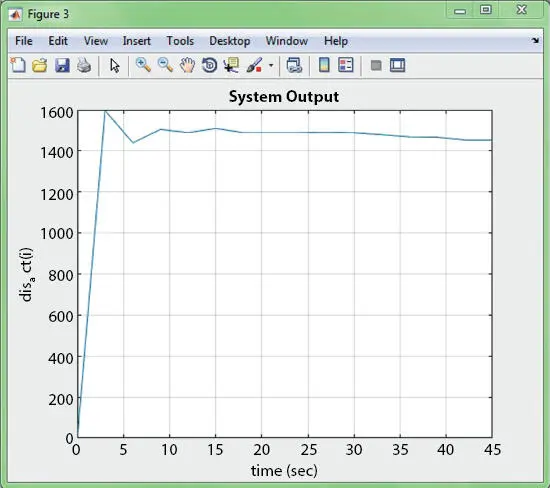

2.6.2.3 Reference = 1,500

When the reference value is set as 1,500 and the Kp, Ki, and Kd values are taken by execution of iterations in GA, then the error is minimized and the displacement is settled at the reference value in the output as shown in Figures 2.15 a, band c.

The Kp, Ki, and Kd values obtained by GA are 0. 38281, 0.19672, and 0.24252.

Figure 2.14 (a) Control error for reference value 500.

Figure 2.14 (b)Control action for reference value 500.

Figure 2.14 (c)System output for reference value 500 (error).

Figure 2.15 (a) Control action for reference value 1,500.

Figure 2.15 (b)Control action for reference value 1,500.

Figure 2.15 (c)System output for reference value 1,500.

Читать дальше