James A. Jahnke - Continuous Emission Monitoring

Здесь есть возможность читать онлайн «James A. Jahnke - Continuous Emission Monitoring» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Continuous Emission Monitoring

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 80

- 1

- 2

- 3

- 4

- 5

Continuous Emission Monitoring: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Continuous Emission Monitoring»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

The new edition of the only single-volume reference on both the regulatory and technical aspects of U.S. and international continuous emission monitoring (CEM) systems Continuous Emission Monitoring

Continuous Emission Monitoring:

Continuous Emission Monitoring, Third Edition

Continuous Emission Monitoring — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Continuous Emission Monitoring», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

MODULAR SAMPLING SYSTEMS

Miniaturization in extractive sampling system design has gone a step further through the development of modular, miniaturized sampling systems. Sponsored by the Center for Process Analysis and Control (CPAC), at the University of Washington, a consortium of equipment manufacturers and end‐users was formed for this purpose. Intended primarily for the process industries, refineries, and chemical companies, the “New Sampling Sensor Initiative” or “NeSSI” established the ISA standard, ISA 76.00.02‐002, for the design of modular sampling platforms (ANSI/ISA 2002). The goals of the program were to simplify and standardize sampling system design by using modular flow components that could be arranged like building blocks.

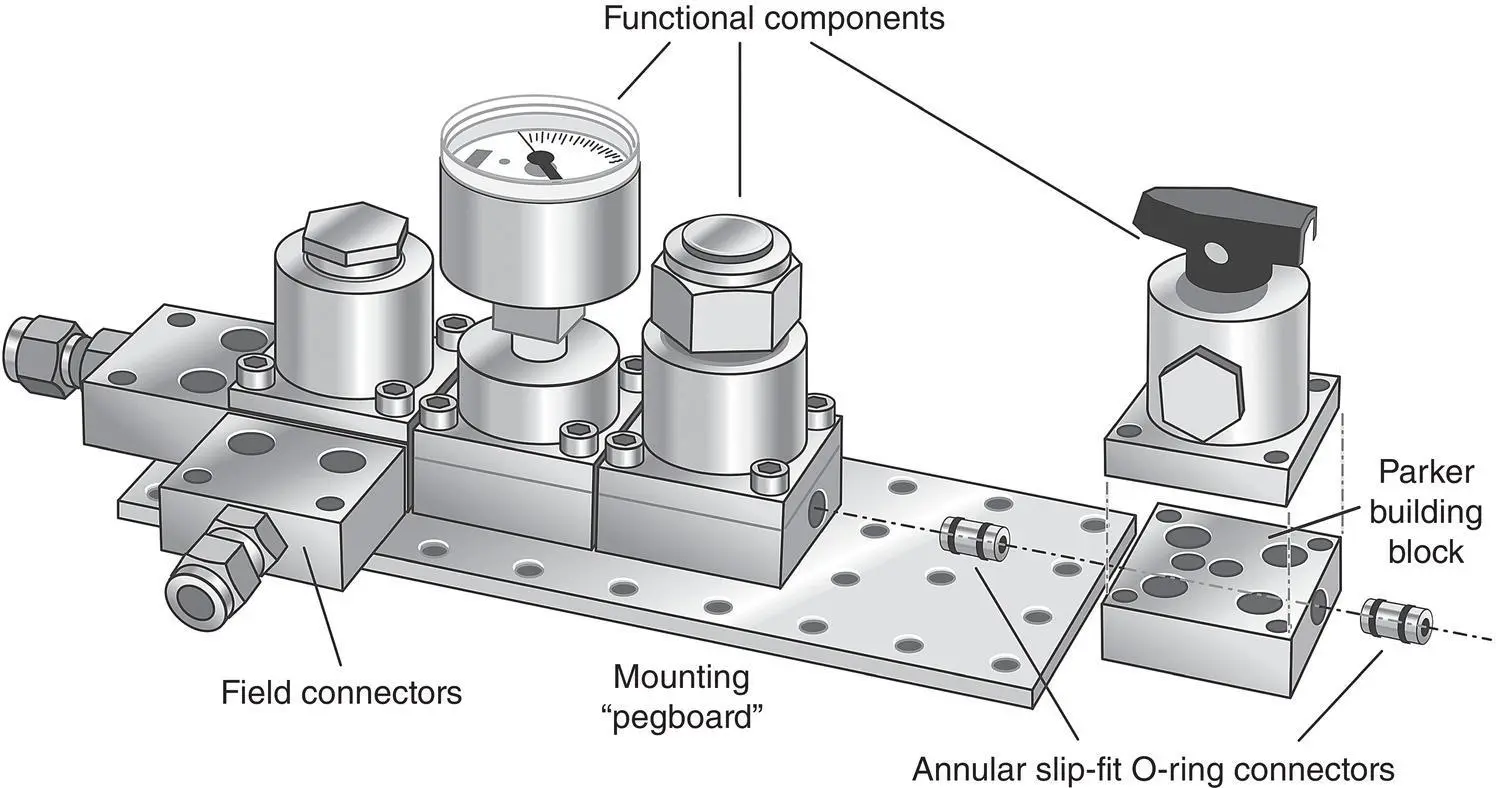

Derived from modular concepts developed in the semiconductor industry, functional components such as valves, gauges, regulators, sensors, and analyzers are mounted on interconnected building blocks. The standard specifies that each building block is to have a “footprint” of about one and a half square inches. The building blocks are machined with holes and passages in configurations that allow the functional components to be interconnected. Instead of stainless steel or Teflon tubing with nut and ferrule fittings, common in traditional extractive systems, the functional components (valves, gauges, regulators, and so on) are interconnected by the use of annular o‐ring slip‐fit pressure connectors or connecting tubes having specially designed o‐ring boss end fittings.

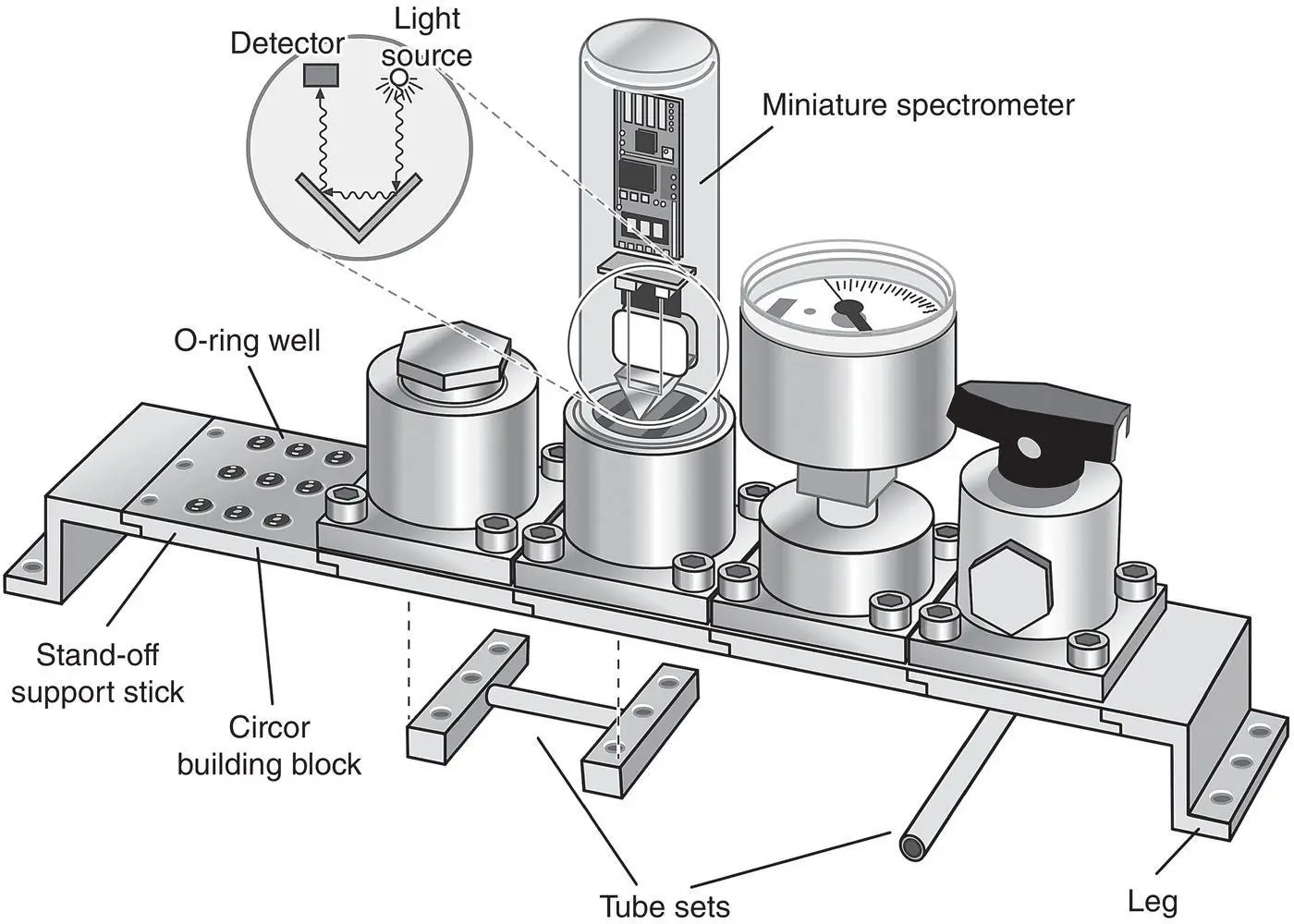

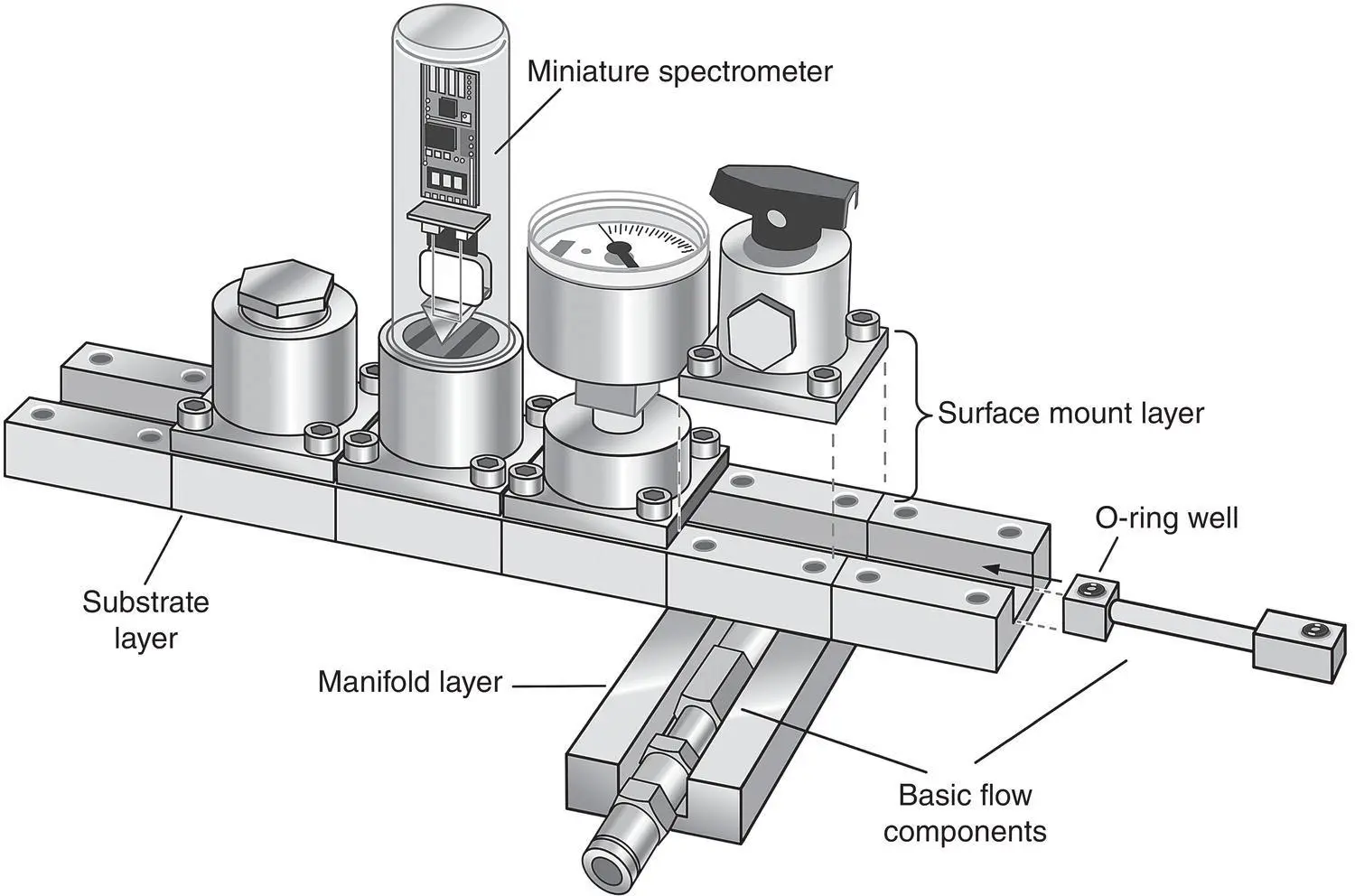

Parker‐Hannifin, Swagelok, and Circor have designed ISA 76–compliant sampling systems; however, each company uses their own approach to interconnecting the blocks ( Figure 3‐28a– c).

In the Parker‐Hannifin system (Dudley and Cost 2012), the modular blocks are arranged on a pegboard, or other support, where they are interconnected by annular slip‐fit pressure connectors. The flow channels of the Parker‐Hannifin system are all in one plane, allowing for straightforward topology.

In the Circor system (Sherman 2005), the building blocks interlock, creating their own structure, which then may be mounted on a plate using a stand‐off support. The system utilizes a single building block in conjunction with various types of tube sets (“standard flow tube sets”). Flanges on the blocks allow them to be connected together as a “stick,” with the tube sets connected under the blocks to route the gases through the blocks to the functional components.

In the Swagelok design (Wawroski 2004), interconnecting tubes called “basic flow components” (similar to the Circor tube sets) are inserted in channels machined into a platform called a “substrate layer.” The building blocks are mounted on top of the substrate layer and are interconnected to the flow tubes from the bottom. A separate manifold layer, beneath the substrate layer platform, is used to connect the flows between the substrate channels. The building blocks joined with the valves, regulators, gauges, sensors, and other system components constitute the “surface‐mount” layer.

Figure 3‐28a Parker‐Hannifin NeSSI interconnection system.

Figure 3‐28bCircor NeSSI interconnection system.

Figure 3‐28c Swagelok NeSSI interconnection system.

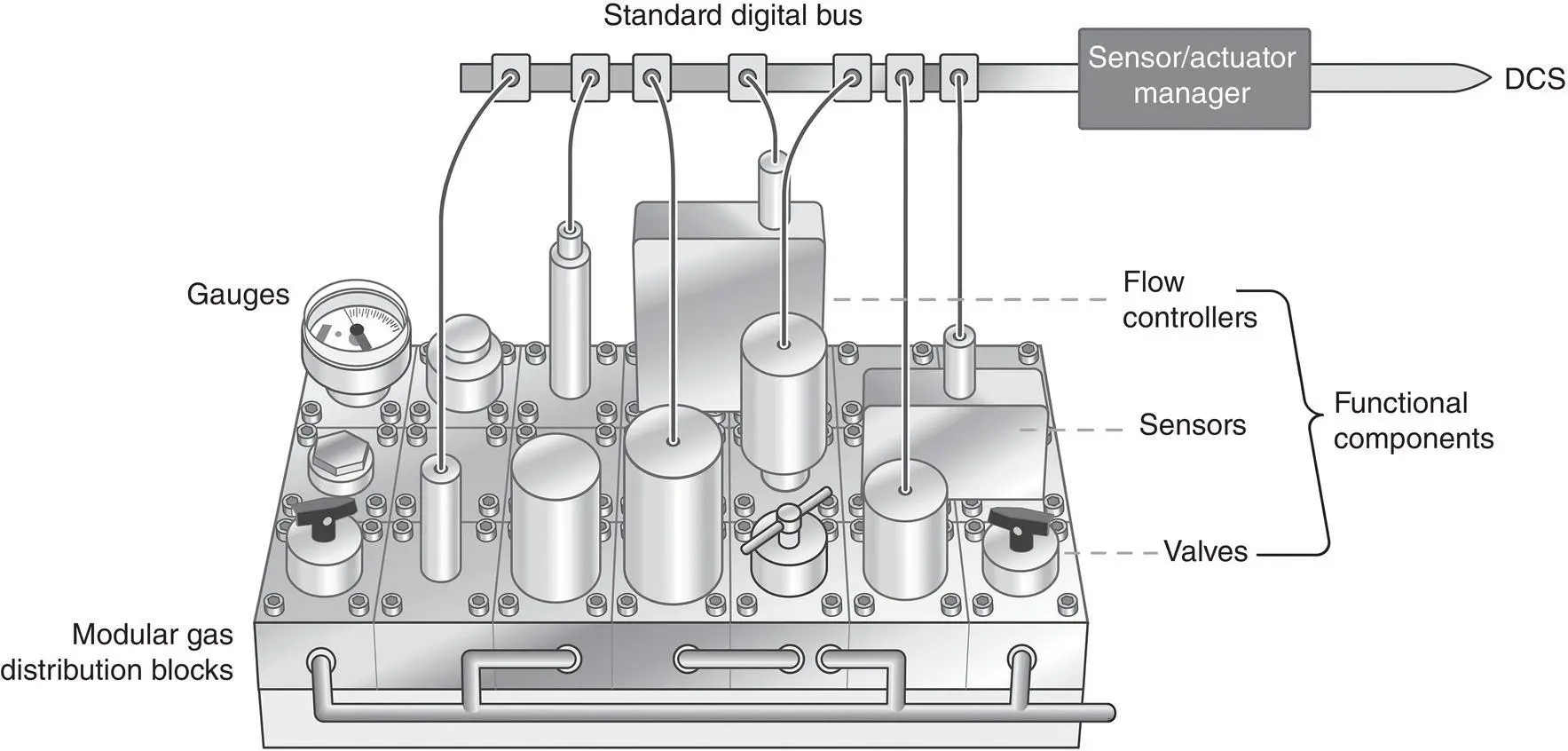

Regardless of the platform, sensors and other system components are accessible from the top of the platform. Translating a traditional flow schematic into a NeSSI system may be challenging for someone unfamiliar with the manufacturer’s architecture. However, computer software has been designed to assist in the development of NeSSI structures from a given schematic. Figure 3‐29illustrates a generic miniature modular CEM system.

Figure 3‐29 Example of a miniature modular CEM system.

These modular sampling systems have less dead space than the tube and fitting system and are less likely to leak than the traditional nut and ferrule fittings by using surface‐mounted o‐rings. However, if a leak occurs, it may be more difficult to find and resolve the leak.

NeSSI systems have seen the greatest application when multiple identical extractive systems are required. In other applications, NeSSI components may be substituted for part of an extractive system, such as the calibration gas distribution system for daily CEM system verifications, or calibration gas dilution systems. The size and modularity of the modular platforms make them ideal for the application of miniature and micro sensors and analyzers (Aquino 2003; Chon 2004). The University of Washington Center for Process Analysis and Control (CPAC) is the primary information resource for conference proceedings, publications, and current progress on NeSSI systems (Dubois 2009; Dubois et al. 2004; Marquardt et al. 2009).

REFERENCES

1 Aldina, G.J. (1985). Continuous Emission Monitoring System for Dry‐Basis Pollutant Mass Rate Measurements. Private communication.

2 American National Standards Institute (ANSI)/Instrument Society of America (ISA) (2002). ISA Standard: Modular Component Interfaces for Surface‐Mount Distribution Components. ISA 76.00.02002. New York.

3 American Society of Mechanical Engineers (ASME) (1971). Fluid Meters – Their Theory and Application, 6ee. New York: ASME.

4 Appel, D. (1994). Calibration of Dilution Extractive Systems. Franklin, MA: Thermo Environmental Instruments, Inc.

5 Aquino, D. (2003). The incredible shrinking sampling system. CEP Magazine. December 2003, 912.

6 Baldwin, T. (1995). Evaluation of stack criteria pollutant gas absorption in the new generation thermoelectric water condenser fitted with laminar impinger type heat exchangers. In: Proceedings of Acid Rain & Electric Utilities: Permits, Allowance, Monitoring, and Meteorology, 555–574. Pittsburgh: Air & Waste Management Association.

7 Batug, J.P., Romero, C.E., Yilmaz, A. et al. (2004). Emission monitoring system and method. US Patent 6,701,255 B2.

8 Baugham, L. (1996). Active control of dilution probes. In: Proceedings – Continuous Compliance Monitoring Under the Clean Air Act Amendments, 154–161. Pittsburgh: Air &Waste Management Association.

9 Baugham, L. (1997). Dilution control method and apparatus. U.S. Patent No. 5,596,154. 21 January 1997.

10 Bembe, R. (2019). Heated sample line maintenance. Power Point Presentation at ESC Fall 2019 User Group Meeting. Austin: Environmental Systems Corporation.

11 Bergshoeff, G. and van Ijssel, F.W. (1978). Monitoring gases – a new stack sampler: Parts 1 and 2. International Environment & Safety March: 32–34; (June):134–136.

12 Berry, R. (1999). Optimizing CEMS Performance Through Advanced QA/QC Practices. TE‐1114127. Palo Alto, CA: Electric Power Research Institute.

13 Berry, R.S. (2000). Evaluating the measurement biases in CEMS. Paper presented at the Air & Waste Management Association Meeting, Salt Lake City, paper 264 (18–22 June 2000).

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Continuous Emission Monitoring»

Представляем Вашему вниманию похожие книги на «Continuous Emission Monitoring» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Continuous Emission Monitoring» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.