1.2 Environmental Management in Industries

Today many industries and companies have recognized the importance of proper environmental management and have switched over from traditional end‐of‐pipe solutions to the integration of environment management in overall management process of the industry. A few major driving forces for such changes are stringent legislation; demand for better work environment for employees; customers' demands; company's image; the growing pressure from all stakeholders regarding the environmental, economical, and social responsibilities. Environmental considerations are no longer regarded on ad‐hoc basis, rather these considerations form the part of industries' everyday reality. Still, there is a lack of holistic approach where environment management is a natural part of overall management system. While the environmental departments are busy with generating reports and petitions for external purposes, the top management is not making use of the competence already present within the organization. The main objective is to focus on the application of various environmental tools and methods so that there could be a shift from reactive regulatory approach to proactive environmental decision making; there could be full support of top management on the environmental information system; and the environmental issues could be prioritized and the implementation could be accelerated. Ultimately, the integration of the environmental responsibility with the environmental systems and allocation of the resources needed shall lead to implementation of the environmental strategies and it can contribute to both improvements in the environmental performance and in increasing long‐term profitability of the industry.

1.2.1 Environmental Challenges

Our avid interest in environmental sustainability and environmental management issues can be traced directly to awareness that as the world's population continues to expand and to consume natural resources, humanity faces shortages that threaten quality of life in developed areas and elsewhere on the Earth, life itself. In attempts to find solutions to these problems, we have created an ever growing inventory of manufactured goods, chemicals, drugs, ostensibly to improve the quality of life that has in fact contributed to the pollution of our environment. “Pollution prevention,” an environmental buzz word since the 1990s, encompasses designing processes that generate no waste to plants that emit only harmless compounds such as pure water.

Zero defect and zero effect (ZDZE) is different from pollution prevention in that it converts raw materials into useful products or valuable resources that have “no defect” in manufactured products and “zero effect” has no adverse effect on health and environment. In this book, the meanings of “Zero Effect,” “Zero Discharge,” or “Zero Emissions” are complimentary and all terms are used interchangeably (Das 2005). Within the ZDZE paradigm the goal of resource extraction, refining, or commodity production is approached in much the same way that the mining, iron and steel, pulp and paper, petroleum, energy, automobiles, petrochemical, pharmaceutical, fertilizer, agricultural, and chemical industries go about processing raw materials. Sometimes the conversion of wastes or by‐products into resources having value to another industry is more efficient than the implementation of pollution prevention techniques – that is industrial ecology (also see Chapter 9).

In this book, we will focus on the best management practices, best available industrial manufacturing processes, techniques, and technologies that treat raw materials into no‐defect products, as well as innovative and emerging processes that have best potential for achieving the highest standards in pollution prevention at the plant and industry levels, leading to no defect and zero effect (NDZE) – a common goal toward industrial environmental management. To move toward NDZE via process pollution prevention (P3) and profitable pollution prevention (P3), industries must use processes that deploy materials and energy efficiently enough to neutralize and control contaminants in the waste stream. The ultimate goal is to remove pollutants from the waste streams and convert them into products or feeds for other processes. Logically then, P3 refers to industrial manufacturing processes by which materials and energy are efficiently utilized to achieve the end product(s) that have “no defect,” while reducing or eliminating the creation of pollutants or waste at the source that is “zero discharge or zero effect.” The primary goal is to educate the engineering students to prepare them as current and future generation engineers who will learn and practice sustainable engineering and who will be our champion stewards in industrial environmental management as needed caretakers of the Earth.

A waste is defined as an unwanted by‐product or damaged, defective, or superfluous material of a manufacturing process. Most often, in its current state, it has or is perceived to have no value. It may or may not be harmful or toxic if released to the environment. Pollution is any release of waste to environment (i.e. any routine or accidental emission, effluent, spill, discharge, or disposal to the air, land, or water) that contaminates or degrades the environment.

1.4 Defining Pollution Prevention

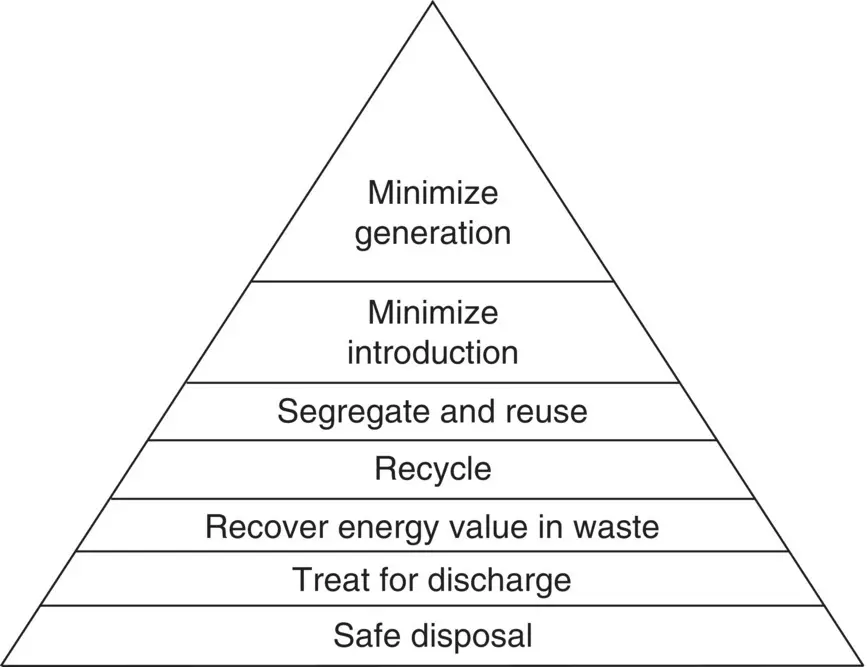

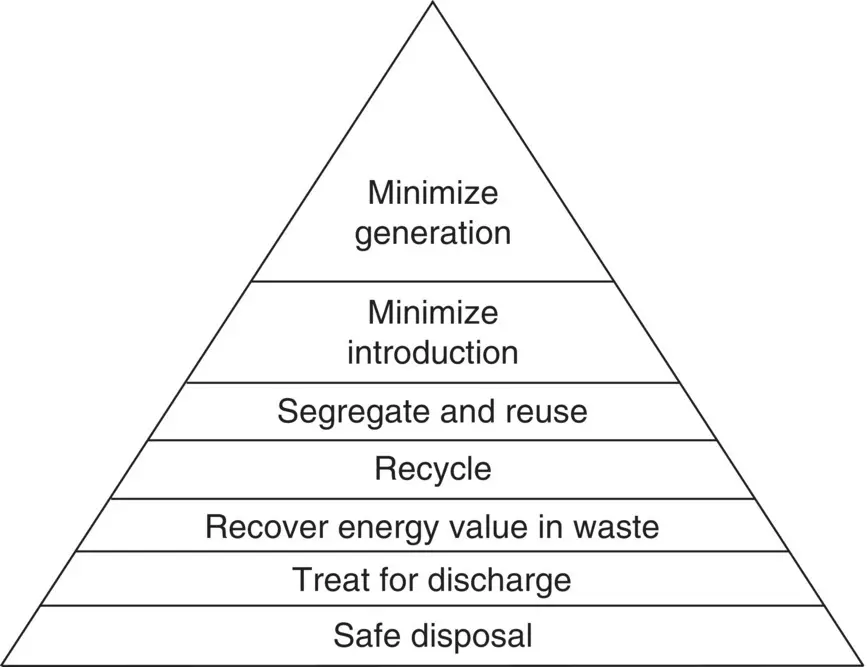

In this book, we define pollution prevention fairly broadly as any action that prevents the release of harmful materials to the environment. This definition manifests itself in the form of a pollution prevention hierarchy, with safe disposal forms at the base of the pyramid and minimizing the generation of waste at the source at the peak ( Figure 1.1).

Figure 1.1 Pollution prevention hierarchy.

In contrast, the U.S. Environmental Protection Agency (USEPA) (1992) definition of pollution prevention recognizes only source reduction and conservation, which encompasses only the upper two tiers in the hierarchy – minimize generation and minimize introduction. The USEPA describes the seven‐level hierarchy of Figure 1.1as “environment management options.” The European Community, on the other hand, includes the entire hierarchy in its definition of pollution prevention. The tiers in the pollution prevention hierarchy are broadly described as follows.

Minimize generation: Reduce to a minimum the formation of nonsalable by‐products in chemical reaction steps and waste constituents (such as tars, fines, etc.) in all chemical and physical separation steps.

Minimize introduction: Cut down as much as possible on the amounts of process materials that pass through the system unreacted or are transformed to make waste. This implies minimizing the introduction of materials that are not essential ingredients in making the final product. For examples, plant designers can decide not to use water as a solvent when one of the reactants, intermediates, or products could serve the same function, or they can add air as an oxygen source, heat sink, diluent, or conveying gas instead of large volumes of nitrogen.

Segregate and reuse: Avoid combining waste streams together with no consideration to the impact on toxicity or the cost of treatment. It may make sense to segregate a low‐volume, high‐toxicity wastewater stream from high‐volume, low‐toxicity wastewater streams. Examine each waste stream at the source and identify any that might be reused in the process or transformed or reclassified as valuable coproducts.

Читать дальше