Manufacturing systems became highly distributed for enhanced flexibility and adaptability to meet the needs of regional markets promptly. The high‐speed 3G, 4G, and 5G wireless networks helped to mobilize product information so that the PLM could be accessed by mobile apps. From the perspective of information technology, we have entered the fourth industrial revolution, where nearly every device will be networked, which allows continuous data streams to populate in memory databases. The Internet of Things (IoT) will transform the manufacturing sector in the coming years. More and more cloud‐based solutions will be available to manufacturing enterprises to support their operations (Bi et al. 2014; Wang et al. 2014; Morley 2014).

Virtual enterprise ( VE ) is a temporary alliance of businesses for partners to share core competencies, resources, and skills in order to take advantage of emerging business opportunities. VE is facilitated by computer networks (Wikipedia 2019d). The core competencies, resources, and skills in VE are mainly for CATs. Figure 1.17shows that using the virtual environment over the Internet, designers across different regions, domains, enterprises, and disciplines can collaborate on all of the CAD activities involved in the lifecycle of product development (Wu et al. 2015; Wu 2014).

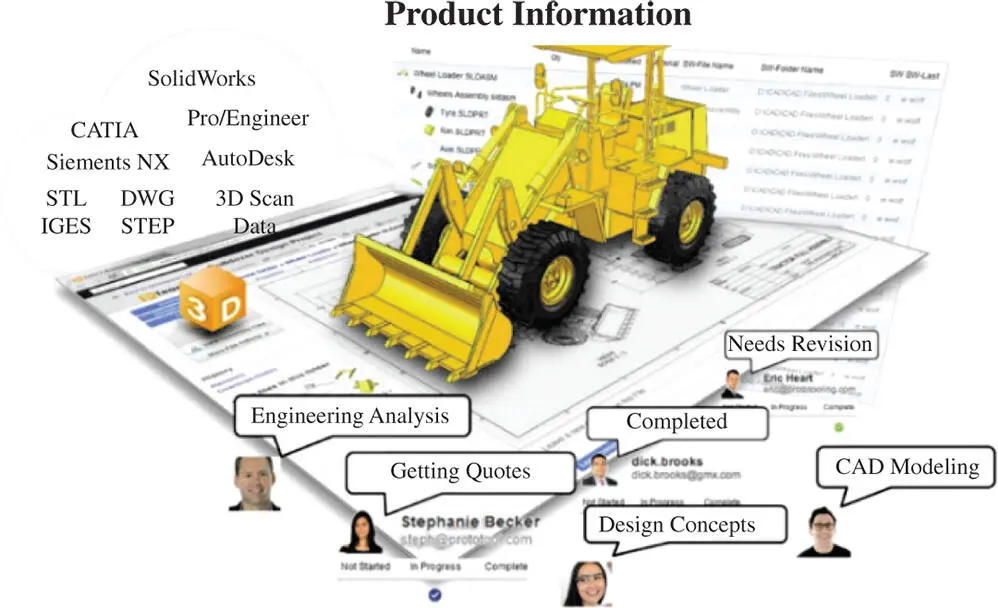

Figure 1.17Computer aided collaboration in virtual environment (Wu et al. 2015; Wu 2014).

1.5 Computer Aided Technologies in Manufacturing

A manufacturing system is involved in numerous decision‐making activities and computers outperform human beings at many tasks in both materials and information flows, such as machine operation, planning and scheduling, engineering, analysis, data acquisition and sharing , computing , data storage , data retrieval , and inspection (Cummings 2014; Sotala 2012). The importance of computer aided technologies can be clearly evidenced by the growing number of computer aided tools exemplified in Figure 1.5. The rapidly developing information technologies (IT) make all of these advanced manufacturing technologies practical.

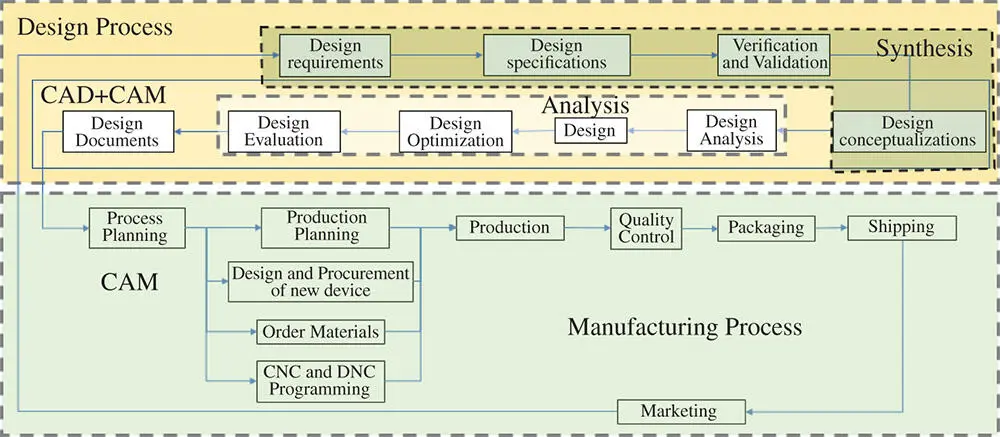

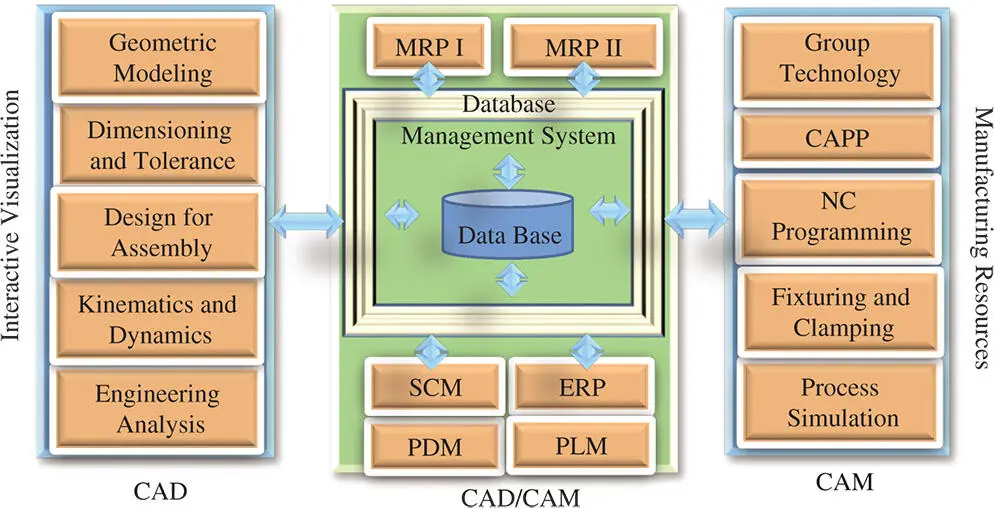

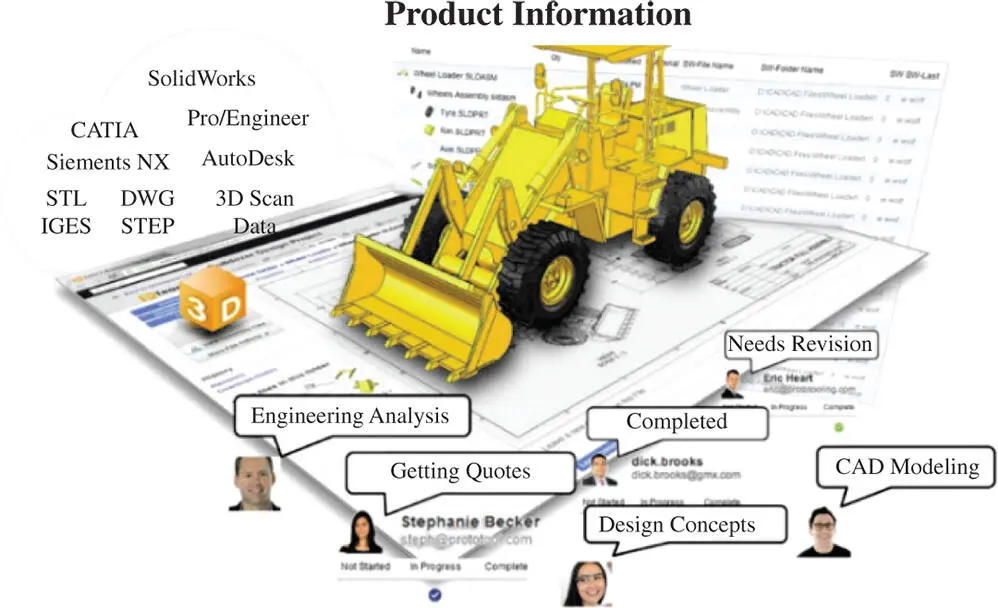

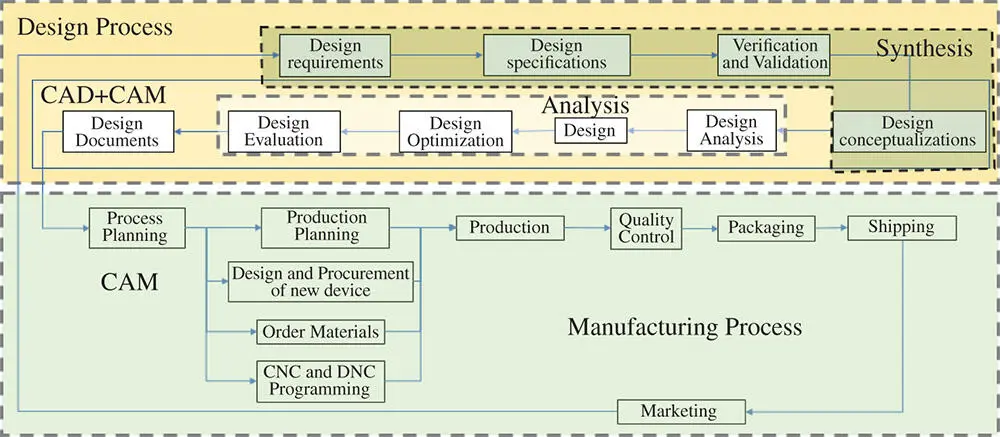

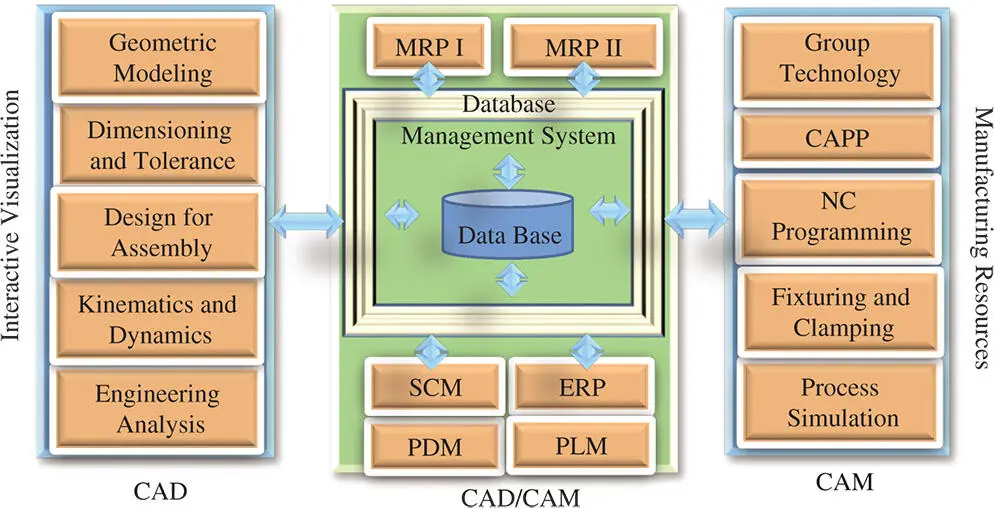

Figure 1.18shows some typical manufacturing activities in a product lifecycle from the identification of design requirements of products to the delivery of final products to end‐users. The fulfilment of these manufacturing activities is mostly assisted by computer programs. For example, CAD tools are used to create, modify, and optimize the design of parts, products, processes, and systems by using computer systems. CAM tools use computer software to control machine tools and related machinery in the manufacture of workpieces. CAD/CAM tools provide an integrated solution to bridge CAD and CAM systems. Figure 1.19gives some typical computer aided tools under the categories of CAD, CAM, and CAD/CAM tools. For example, the CAD tools for geometric modelling , dimensioning and tolerance , design for assembly , kinematic and dynamic simulation , and engineering analysis will be covered in this book.

Figure 1.18CATs in designing, manufacturing, and assembling and system integration.

Figure 1.19Typical computer aided tools in CAD, CAM, and CAD/CAM.

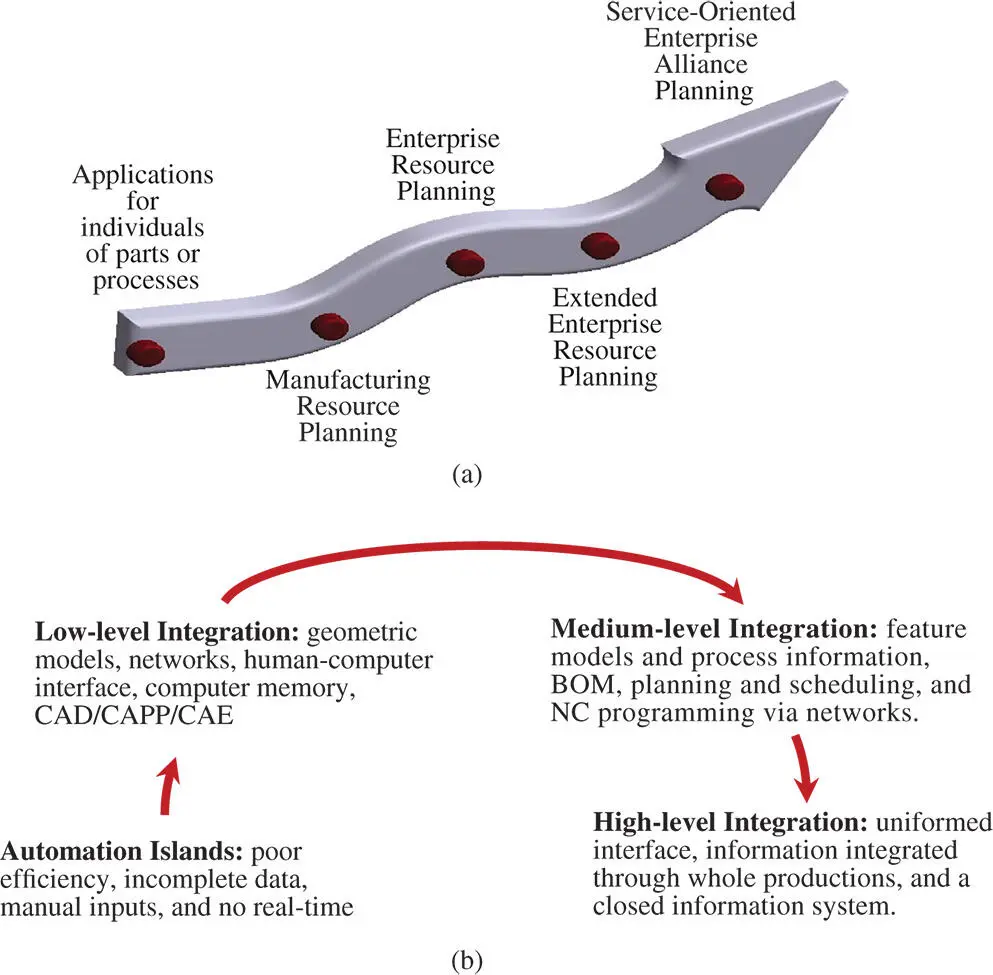

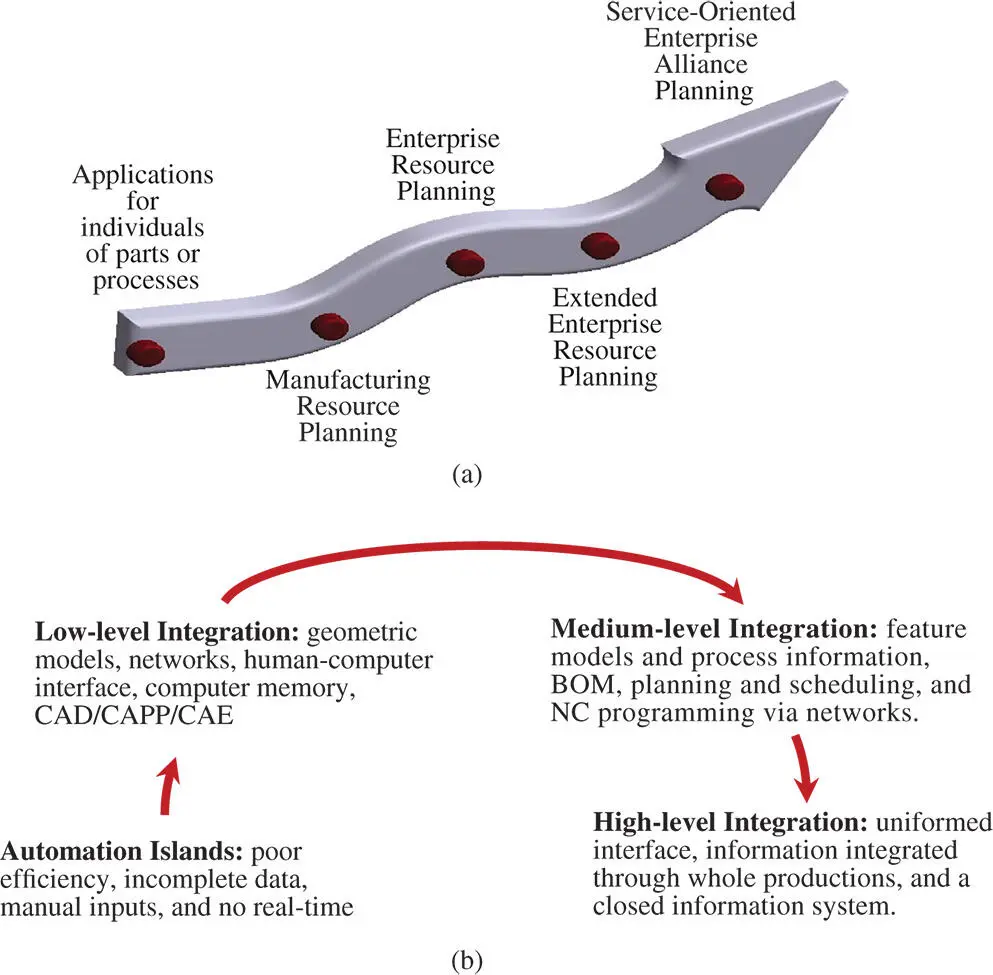

Figure 1.20shows that the capabilities of CATs have been continuously expanded in two aspects: (i) the variety of functionalities from isolated applications for individuals of parts or processes at a lower level to the planning for service‐oriented enterprise alliances at a higher level and (ii) the level of system integration from isolated system components to holistic integration across enterprises.

Figure 1.20The evolution of computer aided technologies in manufacturing, (a) The increasing varieties of system functionalities and (b) the increasing level of system integrations.

1.6 Limitation of the Existing Manufacturing Engineering Curriculum

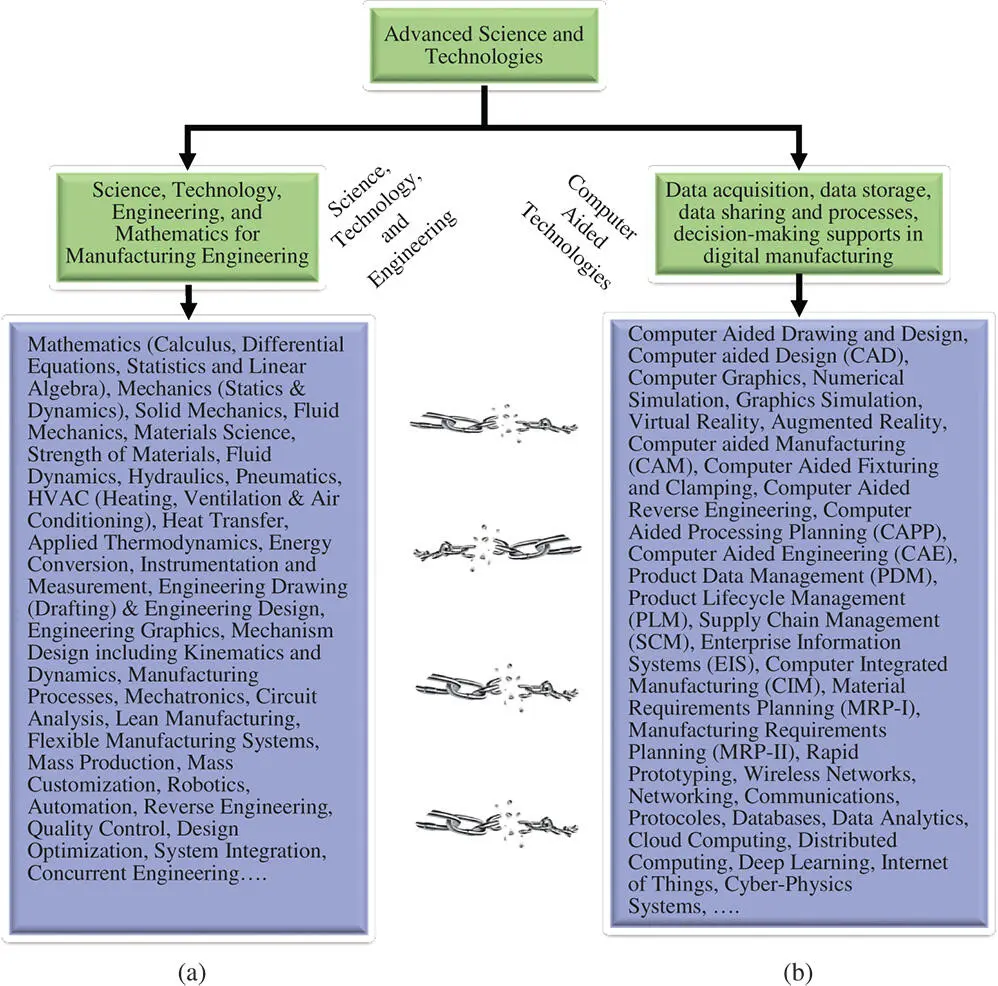

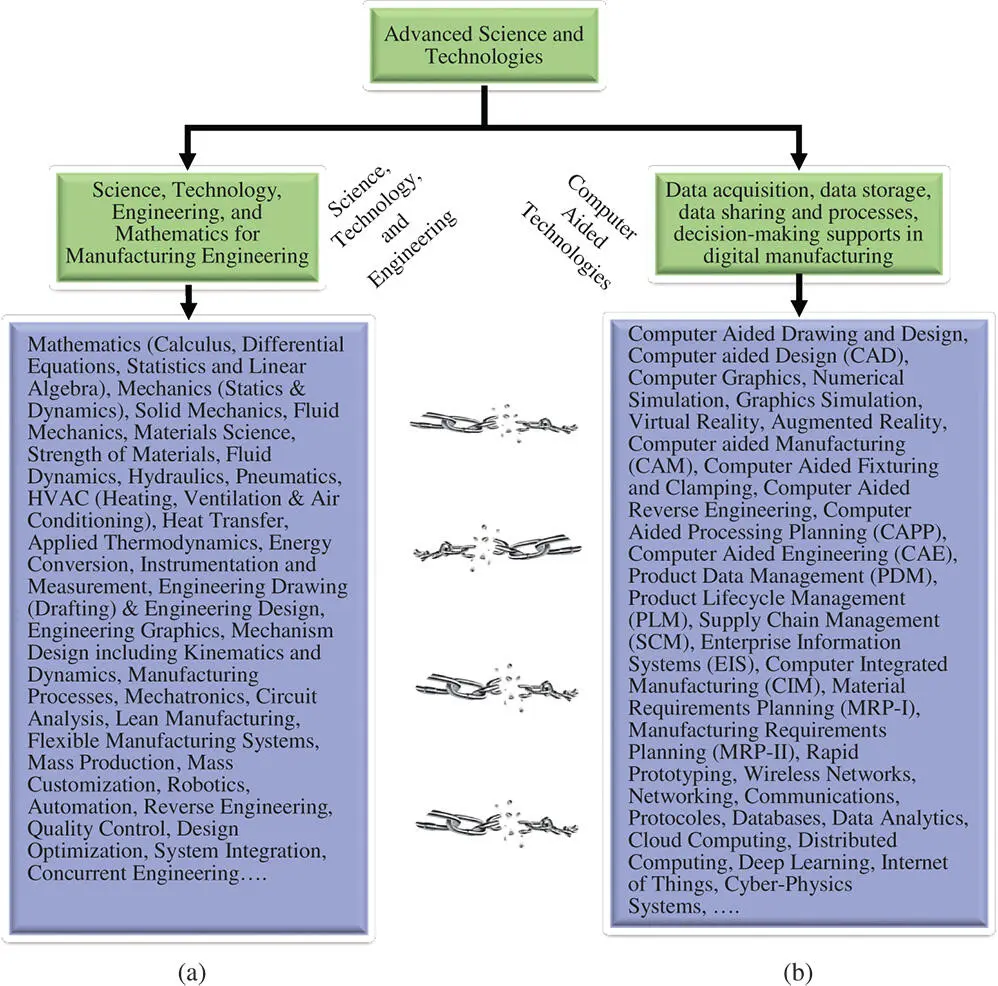

Manufacturing engineering is to apply mathematics and science in practice to design, manufacture, and operate products. Engineers in the manufacturing sector focus on design, development, and operation of manufacturing systems to make competitive products. The existing engineering curricula usually include some core courses in mathematics , physics , computing engineering , and management , as well as some sophisticated courses in mechanical and manufacturing engineering such as materials science , statics and dynamics , thermodynamics , and fluid mechanics . Engineering curricula are generally designed to cover as many sub‐disciplines of mechanical and manufacturing engineering as possible. Students have options to specialize in one or more sub‐disciplines. Some typical courses for the bachelor's degree in design in manufacturing engineering are listed in Figure 1.21a (Wikipedia 2017). From this perspective, existing curricula are mostly discipline‐oriented.

Figure 1.21Mismatch of subdisciplines and computer aided tools in manufacturing engineering. (a) Subdisciplines in manufacturing engineering and (b) computer aided tools in digital manufacturing.

From the perspective of computer aided technologies, numerous computer aided tools become commercially available. However, these software tools are application‐oriented, and most of the tools are developed based on the theories in multiple disciplines. Figure 1.20b shows a list of commonly used computer aided tools in the manufacturing sector. Due to the strong decoupling of multidisciplinary knowledge in these software tools, the classification of disciplines in manufacturing engineering is not well aligned with the classification of available computer aided tools. Figure 1.20shows that there is no one‐to‐one correspondence between sub‐disciplines and available computer aided tools.

The misaligned engineering curricula and a broad scope of computer aided tools in manufacturing pose a great challenge in the teaching of manufacturing engineering. On the one hand , the sub‐disciplines in manufacturing engineering are so diversified that an ever‐increasing number of elective technical courses are needed in engineering programmes. Meanwhile, public education systems are facing the pressure to reduce the number of credit hours for college degrees. Taking as an example the mechanical engineering program at Purdue University, Fort Wayne, the number of required credit hours for a bachelor degree has been reduced from 126 in the spring of 2012 to 120 in the spring of 2017 (Bi and Mueller 2016). On the other hand , engineering programmes are responsible for preparing students for an appropriate set of knowledge and skills using advanced computer aided tools; however, more and more computer aided tools are becoming commercially available and so their functionalities need to be upgraded and expanded continuously. This proves to be a great challenge to integrate disciplinary theories and computer aided tools in the limited selection of engineering courses.

Читать дальше