1 ...7 8 9 11 12 13 ...21 Further polymerization is called end-wise polymerization involving coupling of monolignols with the phenolic end groups of di- or oligolignols or a coupling of two end group free radicals, yielding a branched polymer via tri-, tetra-, penta-, and oligolignols [11].

Summarizing the formation of lignin, as mentioned by Fengel and Wegener [11], it is evident that these macromolecules are not formed by a genetically prescribed regular mechanism, but by a random coupling of lignols to form a nonlinear polymer. The final constitution of lignin is therefore determined mostly by reactivity and the frequency of the building units involved in its polymerization.

Proportions of different types of linkages connecting the phenylpropane units in lignin are given in Table 1.1.

Table 1.1 Proportions of different types of linkages connecting the phenylpropane units in lignin.

|

Percent of the total linkages |

| Linkage typeb |

Dimer structure |

Softwooda |

Hardwooda |

| β- O -4 |

Arylglycerol-β-aryl ether |

50 |

60 d |

| α- O -4 |

Noncyclic benzyl aryl ether |

2–8 c |

7 |

| β-5 |

Phenylcoumaran |

9–12 |

6 |

| 5–5 |

Biphenyl |

10–11 |

5 |

| 4–0–5 |

Diaryl ether |

4 |

7 |

| β-1 |

1,2-Diaryl propane |

7 |

7 |

| β-β |

Linked through side chains |

2 |

3 |

aApproximate values based on data of Adler [26] obtained for MWL from spruce ( Picea abies ) and birch ( Betula verrucosa ).

bFor corresponding structures.

cValues have been reported [25].

dOf these structures, about 40% are of guaiacyl type and 60% are of syringyl type.

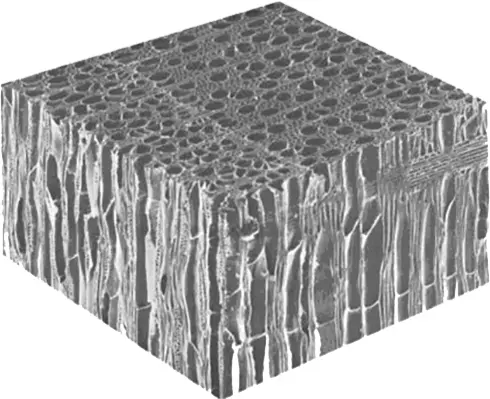

1.5 Influence of Hierarchical Structure of Wood on Wood–Adhesive Interaction

Marra [27] describes the process of adhesive bond formation in a wood substrate by five steps: flow, transfer, penetration, wetting, and solidification. The flow involves the spreading of the liquid on the wood surface. This is followed by transfer of adhesive to the adjacent wood surface. Capillary forces within the cell lumens promote penetration, and bulk flow occurs due to applied pressure. Wetting of the wood surface by the adhesive occurs to an optimum extent, which promotes the molecular contact between the adhesive and wood surface. Finally, solidification occurs as a result of the formation of three-dimensional cross-linked structure when the glue line is exposed to high temperature.

Penetration of adhesive into the porous network of wood cells is believed to have a strong influence on bond strength [28–30].

Damaged wood cells may be reinforced by the adhesive, and stresses may be more effectively distributed within a larger interphase region. The optimum depth of penetration is required to ensure mechanical adhesion [31], but excessive penetration causes insufficient adhesive remaining at the interface [27], leading to a starved bondline. This constitutes a weak boundary layer and a weak spot in the chain (see Figure 2.7) of Marra’s chain-link analogy [27] (see Section 2.15). This analogy emphasizes the fact that the overall strength of an adhesive bond in a composite is determined by the weakest portion of the chain. In other words, an adhesive bond is just as good as the weakest link in the chain. In this respect, adhesive penetration plays a vital role in this analogy.

The hierarchical structure of wood profoundly influences the adhesion phenomenon over a wide range of “length scales”. The adhesive phenomenon occurs first by transport phenomenon (bulk flow, penetration, and diffusion) followed by a number of possible processes ranging from mechanical adhesion to the formation of chemical bonds as shown in Table 1.3. Adhesive penetration in wood is commonly categorized into (a) gross penetration and (b) cell wall penetration. Gross penetration is the flow of liquid adhesive into the porous structure of wood in order to fill the lumens. For cell wall penetration, the adhesive enters the woody cell wall. Adhesive gross penetration and cell wall penetration are both critical to the performance and durability of adhesive joints [32–35].

1.5.1.1 Penetration in Different Size Scales

Laborie proposed a categorization of adhesive penetration in wood in terms of different size scales of adhesive penetration [32]. Accordingly, in the following classification, four scales of penetration are envisioned:

1 Macroscopic penetration (millimeters)

2 Microscopic penetration (microns to tens of microns)

3 Nanoscale penetration (nanometers to tens of nanometers)

4 Angstrom scale penetration (up to tens of angstroms)

Wood as a porous, cellular material displays roughness on the micron scale but can also exhibit roughness on the millimeter scale, depending on how a particular wood element to be bonded is produced. For example, production of rotary-peeled veneer can produce roughness on a millimeter scale due to the creation of lathe checks. Pores or free volume also occur within the amorphous regions of the cell wall material on the molecular level. The length scales over which the wood–adhesive interactions occur are given in Table 1.2[36].

Table 1.2 Comparison of wood–adhesive interactions relative to length scale.

| Component |

μm |

nm |

| Adhesive force |

0.0002–0.0003 |

0.2–0.3 |

| Cell wall pore diameter |

0.0017–0.002 |

1.7–2.0 |

| PF resin molecular length |

0.0015–0.005 |

1.5–5.0 |

| Diameter of particles that can pass through a pit |

0.2 |

200 |

| Tracheid lumen diameter |

4–25 |

|

| Glue line thickness |

50–250 |

|

In order to understand the adhesion phenomenon operating at different size scales in wood, the values of size scales shown in Table 1.2should be viewed in conjunction with the length scale (as shown in Table 1.3) [37] over which different wood–adhesive interactions take place.

Table 1.3 Comparison of adhesion interactions relative to length scale [36].

| Category of adhesion mechanism |

Type of interaction |

Length scale |

| Mechanical |

Interlocking or entanglement |

0.01–1000 μm |

| Diffusion |

Interlocking or entanglement |

10 nm-2 nm |

| Electrostatic |

Charge |

0.1–1.0 μm |

| Covalent bonding |

Charge |

0.1–0.2 nm |

| Acid-base interaction |

Charge |

0.1–0.4 nm |

| Lifshitz van der Waals |

Charge |

0.5–1.0 |

In its most simple approach, adhesive penetration can be measured in terms of depth of penetration. It typically spans from fractions of millimeters to several millimeters. One may therefore term this scale of penetration as macroscopic penetration.

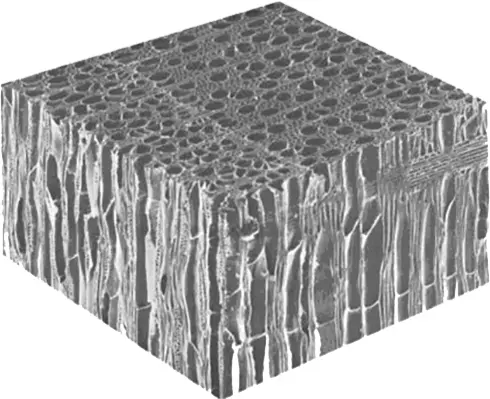

A finer observation scale of adhesive domains can be understood by reference to wood anatomy. Hierarchically structured wood is an orthotropic material, in which arrays of cells are aligned along the longitudinal and radial directions ( Figure 1.9).

Figure 1.9 Arrays of cells aligned along the longitudinal and radial directions.

Читать дальше