Allan T. Kirkpatrick - Internal Combustion Engines

Здесь есть возможность читать онлайн «Allan T. Kirkpatrick - Internal Combustion Engines» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Internal Combustion Engines

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

Internal Combustion Engines: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Internal Combustion Engines»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

New engine technologies and concepts Effects of engine speed on performance and emissions Fluid mechanics of intake and exhaust flow in engines Turbocharger and supercharger performance analysis Chemical kinetic modeling, reaction mechanisms, and emissions Advanced combustion processes including low temperature combustion Piston, ring and journal bearing friction analysis The

expands on the combined analytical and numerical approaches used successfully in previous editions. Students and engineers are provided with several new tools for applying the fundamental principles of thermodynamics, fluid mechanics, and heat transfer to internal combustion engines.

Each chapter includes MATLAB programs and examples showing how to perform detailed engineering computations. The chapters also have an increased number of homework problems with which the reader can gauge their progress and retention. All the software is ‘open source’ so that readers can see in detail how computational analysis and the design of engines is performed. A companion website is also provided, offering access to the MATLAB computer programs.

= −180

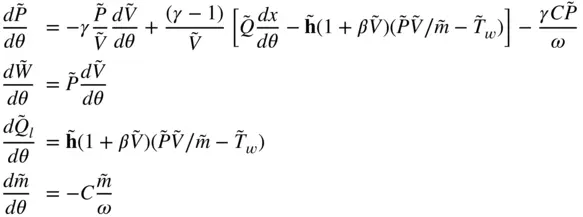

= −180  ), with initial inlet conditions given. The integration proceeds degree by degree to top dead center and back to bottom dead center. Once the pressure and other terms are computed as a function of crank angle, the overall cycle parameters of net work, thermal efficiency, and imep are also computed. The use of the program is detailed in the following example.

), with initial inlet conditions given. The integration proceeds degree by degree to top dead center and back to bottom dead center. Once the pressure and other terms are computed as a function of crank angle, the overall cycle parameters of net work, thermal efficiency, and imep are also computed. The use of the program is detailed in the following example. rpm with a compression ratio

rpm with a compression ratio  , bore

, bore  m, and stroke

m, and stroke  m. The cylinder wall heat transfer coefficient

m. The cylinder wall heat transfer coefficient  W/

W/  ‐K, the cylinder wall temperature

‐K, the cylinder wall temperature  K, and the mass transfer parameter is

K, and the mass transfer parameter is

. The initial cylinder pressure,

. The initial cylinder pressure,  , at bottom dead center is 1 bar, with a temperature

, at bottom dead center is 1 bar, with a temperature  at bottom dead center of 300 K. The heat addition,

at bottom dead center of 300 K. The heat addition,  = 1190 J, and the combustion duration

= 1190 J, and the combustion duration  is constant at 40 degrees. Assume that the ideal gas specific heat ratio

is constant at 40 degrees. Assume that the ideal gas specific heat ratio  is 1.4.

is 1.4. −20

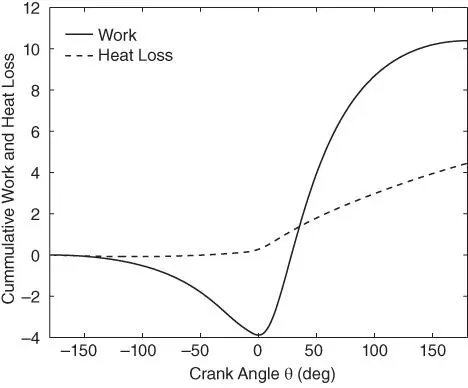

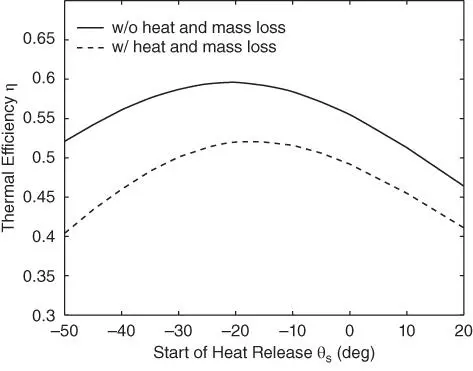

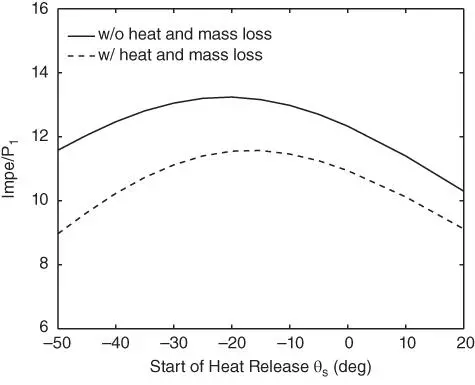

−20  . The cumulative work is initially negative due to the piston compression, and becomes positive on the expansion stroke. The heat transfer loss is very small during compression, indicating a nearly isentropic compression process, and is somewhat linear during the expansion process.

. The cumulative work is initially negative due to the piston compression, and becomes positive on the expansion stroke. The heat transfer loss is very small during compression, indicating a nearly isentropic compression process, and is somewhat linear during the expansion process. btdc, and the peak pressure crank angle remains at +11

btdc, and the peak pressure crank angle remains at +11  atdc. Experimentally, the optimum ignition timing, which gives maximum imep is measured on a brake dynamometer, and indicates the maximum brake torque (MBT) for a given throttle position. MBT timing is discussed in more detail in Chapter 13.

atdc. Experimentally, the optimum ignition timing, which gives maximum imep is measured on a brake dynamometer, and indicates the maximum brake torque (MBT) for a given throttle position. MBT timing is discussed in more detail in Chapter 13.

= −20

= −20  and

and  = 40

= 40