| Material |

Ratio of sample to Li 2B 4O 7 |

Ratio of sample to Li 2B 4O 7+ LiBO 2(mixture of 1 : 1) |

Ratio of oxidizer (LiNO 3) to the sample flux mix |

| Alumina |

|

0.6 : 6 |

|

| Bauxite |

|

0.5–1 : 6 |

|

| Cement |

2–3 : 6 |

|

|

| Chromium oxide |

|

0.1 : 10 |

|

| Coal ash |

0.6 : 6 |

|

1 : 1 |

| Ferric oxide |

|

0.4 : 6 |

|

| Ferrous oxide |

|

0.4 : 6 |

1 : 1 |

| Magnesia |

0.6 : 6 |

|

|

| Rocks |

|

0.5–1 : 6 |

|

| Silica |

|

1 : 6 |

|

| Slags |

0.5–1 : 6 |

|

|

| Sulfate |

|

1 : 6 |

|

| Sulfide concentrates |

0.3–0.6 : 6 |

|

2–3 : 1 |

| Sulfide ores |

0.4–0.8 : 6 |

|

2 : 1 |

| Titania |

|

0.4–0.6 : 6 |

|

| Zirconia |

|

0.4–0.6 : 6 |

|

The fluxes are used in varying ratios to the sample and sometimes also with an additional oxidizer depending on the different sample qualities. Table 3.10gives an overview of the different types of powder materials, the ratio of the amount of the flux to the amount of the sample to be used, and if an additional oxidizer is recommended. The weighing should be carried out with an uncertainty of approximately 1 mg. In any case, it is recommended to make tests in the preparation of the different sample qualities to ensure the manufacturing of high-quality fusion beads.

It has to be taken into account that due to the flux the sample is diluted, which means both the slope of the calibration curve and the sensitivity of the analysis will be reduced with increasing flux content.

Fluxes are hygroscopic, in particular lithium tetraborate. Therefore, the melting agents should be dried before use, and preheating at 105 °C over a longer period (overnight) is recommended.

Other additives are sometimes also used in the melting process. These may be oxidizing agents and glass-forming agents, but also substances that aim to improve the quality of the fusion bead or have an influence on the analytical process.By strong absorbers, such as BaO or La2O3, the matrix interaction is increased and fusion beads can then be treated as infinitely thick samples, in which the intensity of the fluorescence signal does not depend on the sample thickness, i.e. their information depth is smaller.

Sometimes, also lithium bromide (LiBr), lithium iodide (LiI), or ammonium iodide (NH4I) is added to the molten sample in small amounts (one or two drops) to increase the surface tension of the melt (especially when using lithium metaborate as flux). This allows for a loss-free pouring of the melt into the cooling mold and a subsequent simple separation of the sample from the mold. For these additives, care must be taken again that no interferences with analyte elements occur. Examples are overlaps of the Br-Lα line with the Al-Kα line or the Mg-Kα line, and the I-Lβ lines with the Ti-Kα line. However, the contents of Br and I in the fused bead are very small, also caused by their high volatility. At the melting point of lithium metaborate half of the initial amount of Br or I is evaporated within approximately eight or two minutes, respectively.

A good mixture of the sample material, additives, and the melting agent is very important. It should be carried out in ball mills in order to prevent segregation of the different components. Mixing in the melting vessel does not lead to a sufficient result and can also disturb the surface of the crucible, which can prevent the complete pouring of the sample or lead to its early destruction.

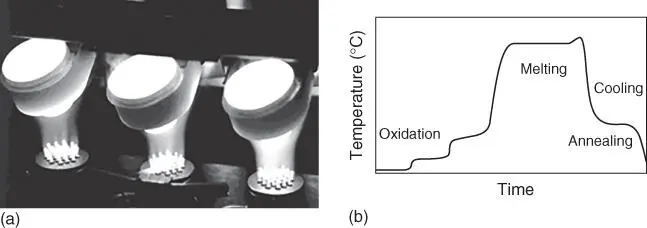

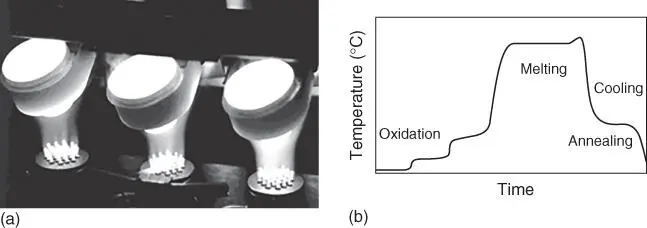

The oxidation and melting process usually take place above a gas flame, but electrically heated muffle furnaces are also used. In order to increase the productivity of the sample preparation, usually several samples can be processed simultaneously.A mound in the bottom of the Pt mold improves the mixing effect during the pivoting of the crucible.

In order to increase the quality of the fusion beads and to standardize them, the temperature profiles of the ovens are mostly controllable. The temperatures for the melt process should be about 150–200 °C above the melting point of the melt. However, in order to reduce the loss of volatile elements such as alkali metals or sulfur, the melting temperatures should not be too high. This can be achieved using Na2B4O7 (see Table 3.9).

Equipment for fusion melting is offered by companies such as Claisse Inc., Fluxana GmbH, or XRF Scientific Ltd. (Table B.1). All of them are temperature controlled, mix the melt automatically by pivoting or rotating the crucible during the melting process, and pour the melt into a preheated casting mold, which is then cooled by a predetermined temperature profile. The casting mold then already has the required size of the X-ray spectrometer being used. The companies also offer prepared recipes for the preparation of a wide variety of sample materials.

Figure 3.14ashows the Pt crucible over a burner during the melting process, and Figure 3.14ba typical temperature profile for the complete melting process.

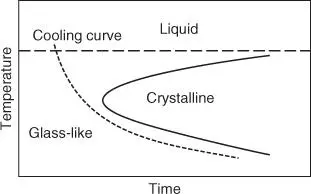

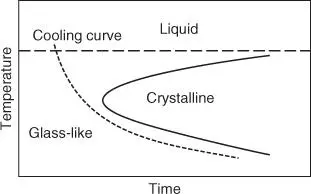

The cooling process strongly influences the quality of the glass beads as well. The aim is to prepare stress-free and homogeneous glass-like beads. The influence of the cooling rate on the quality of the glass beads is shown in the graph of Figure 3.15. In order to avoid crystallization of the sample material, sufficient rapid cooling is required. On the other hand, too rapid cooling can lead to high stresses in the bead, which can result in the breakage of the bead; at a minimum it leads to micro-cracks or milky beads. Therefore, the casting molds are preheated before casting, and cooled by an air flow to appropriately control the cooling process. This procedure also depends on the respective melting agent, additives, and the sample material, and must be optimized by testing. In selecting the flux, a shift in the separation between amorphous and crystalline condensation along the time axis according to Figure 3.15is possible, i.e. the cooling rate can be influenced. However, one has to take into account that the various melting agents have different dissolving properties.

Figure 3.14 (a) Pt crucibles over a gas burner. (b) Temperature profile of the melting process.

Figure 3.15 Cooling curve to produce glass pellets.

The manufacturing of fusion beads requires not only a relatively long time, but also a high manual effort. Various efforts have been made to automate this process (see for example Flock and Ohls 1987).

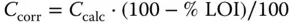

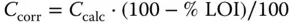

During the melting process, the weight of the sample can be changed due to the loss of volatile elements or compounds, especially by the evaporation of moisture or gas inclusions in the sample material. This loss – LOI – must be taken into account in the later quantification. The following relationship is used:

(3.2)

Читать дальше