Advantages of microwave heating can be accrued in one of three ways: (i) as a pre-dryer, (ii) as a booster dryer, or (iii) as a post-dryer. When used as a pre-dryer, volumetric heating due to microwave quickly forces internal moisture to the surface, facilitating the optimal operation of a conventional dryer. In booster drying, microwave energy is added as the drying rate begins to fall off, thereby sustaining or even increasing the drying rate. When used as a post-dryer, the microwave system greatly improves drying efficiency of the conventional dryer since the last one-third of water is most difficult to remove by the conventional dryer alone.

Microwave drying also produces clean coal with low-sulfur content using the ability to preferentially direct the microwave energy at the pyrite (FeS 2) in coal giving rise to localized thermo-desulfurization reaction between pyritic sulfur and other neighboring reactive compounds present in the solid (Weng and Wang, 1992). The polarization of microwave fields results in the cleavage of the iron-sulfur bonds, releasing sulfur in the form of hydrogen sulfide (H 2S), carbonyl sulfide (COS), or sulfur dioxide (SO 2).

3.6.4 Screw Conveyor Dryers

When there is need for simultaneous conveying and heating or cooling, a screw conveyor can be easily converted to a dryer or heat exchanger by providing the necessary heat to the moving solids either directly or indirectly and by removing the evaporated moisture by gentle gas flow or by application of vacuum (Osman et al ., 2011).

Typically, a screw conveyor dryer consists of a jacketed vessel (generally cylinder or U-trough) in which material is simultaneously heated and dried as it is conveyed. The heating medium, usually hot water, steam, or any thermal fluid, may also flow through the hollow flights and shaft to provide high heat transfer area without the need for additional space or material.

The screw conveyor dryer is essentially a modified screw conveyor system. Therefore successful implementation of the screw conveyer dryer not only depends on the target output properties of the processed coal, but also on the screw dynamics and physical attributes. To determine a suitable screw configuration, physical characteristics of the material to be handled such as flow pattern (related to angle of repose), abrasiveness, and size must be known beforehand. Subsequently, the volumetric feed rate, screw speed, screw size, power requirement, heat requirement, and length of screw can be determined.

3.6.5 Superheated Steam Dryer

Although the concept of drying using superheated steam was conceived more than a century ago, serious interest in superheated steam drying has emerged in the last three decades (Mujumdar, 1990). Many benefits are associated with superheated steam drying, which include (i) the reduced risk of spontaneous combustion, (ii) the increased drying rates, (iii) the better energy efficiency, and (iv) the improved grindability of the coal (Osman et al ., 2011).

In the process, the optimum pressure and drying time depend on the size of the coal particles and the resulting moisture content of the dried particle depends on the steam pressure and temperature, the particle size and moisture content of the coal feedstock.

Superheated steam drying requires less energy than hot gas dryer because there is no need to supply coal moisture with latent heat of vaporization. Drying in superheated steam also increases the apparent density of low-rank coal due to shrinkage of the particles on moisture removal. In addition, the decomposition of sulfur functional groups during steam drying process produces cleaner coal with high heating value. Because fire hazards associated with the spontaneous combustion of coal are eliminated in the superheated steam drying process, the target moisture content can be achieved in a short time by using higher steam temperature.

The total sulfur content of a raw coal is distributed throughout the macerals and minerals present and may occur as elementary sulfur, as sulfates, as sulfides, or in organic combination in the coal (Speight, 2013).

It has been customary to classify the forms of sulfur as inorganic, pyritic, and organic; inorganic sulfur comprising the sulfates, pyritic the sulfides, and organic the remainder, including any elemental sulfur that may be present. Standard methods of analysis have been devised for direct determination of total sulfur, sulfate sulfur, and pyritic sulfur, the organic sulfur being reported as the difference between the total sulfur content and the sum of sulfate content plus pyritic sulfur content. On a more localized basis such as in the United States ( Chapter 1), the sulfur content will vary significantly by region ( Table 3.7) thereby creating issues arising from sales to regional power producers because of the various laws relating to emission of sulfur oxides.

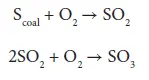

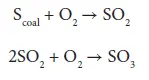

Even when coal has been prepared to meet the specifications for size, mineral (ash), and moisture contents, it may still be dirty by environmental standards. In this case, the important contaminant is sulfur, which is converted, during combustion, to gaseous product(s):

Table 3.7 Sulfur distribution in selected US Coals (Speight, 2013).

| Region |

Total sulfur (%) |

Inorganic sulfur (%) |

Organic sulfur (%) |

Inorganic/total sulfur (%) |

| Northern Appalachia |

3.01 |

2.01 |

1.00 |

67 |

| Southern Appalachia |

1.04 |

0.37 |

0.67 |

36 |

| Alabama |

1.33 |

0.69 |

0.64 |

52 |

| Eastern Midwest |

3.92 |

2.29 |

1.63 |

58 |

| Western Midwest |

5.25 |

3.58 |

1.67 |

68 |

| Western |

0.68 |

0.23 |

0.45 |

34 |

| Total United States |

3.02 |

1.91 |

1.11 |

63 |

Unless removed, the sulfur oxides end up as stack gas emissions.

In recent years, deliberate attempts been made to achieve coal desulfurization on an industrial scale by modification of the coal preparation practices. In part, this has been due to development of more precise methods for the separation of coal and minerals. However, these practices are usually very dependent upon the coal properties. Thus, where low-sulfur coal feedstock is a necessity, the deliberate selection of naturally occurring low-sulfur coal has been the most effective solution and has been the practice followed in producing metallurgical coals, political aspects notwithstanding as evidenced by the selection of higher sulfur (and inappropriate) coal for politically sensitive, rather than market, satisfaction.

There are strong incentives to develop processes for removing sulfur from coal before combustion (precombustion cleaning), during combustion or after combustion (post combustion cleaning) ( Chapters 12, 13, 14).

Indeed, since the passage of the original Clean Air Act of 1970, subsequently amended in November 1990, coal preparation efforts in the United States have emphasized development of technology for the reduction of sulfur.

Coal desulfurization can be achieved on a commercial scale by means of physical or physicochemical methods which generally use the principal of density separation techniques or other techniques that exploit the surface properties of coals and minerals. For example, the methods exploit the difference in properties that exist between the various forms of inorganic sulfur [pyrite and/or marcasite (FeS 2)and occasionally including galena (PbS)] and sulfur in the organic matrix of the coal.

Читать дальше